Multifunctional rubber modifier for all-steel radial tire and preparation technology thereof

A rubber modifier and multi-functional technology, applied in the field of rubber modifiers, can solve the problems of poor hydrolytic stability and single function of borate esters, and achieve the effects of easy production, simple operation, and improved cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

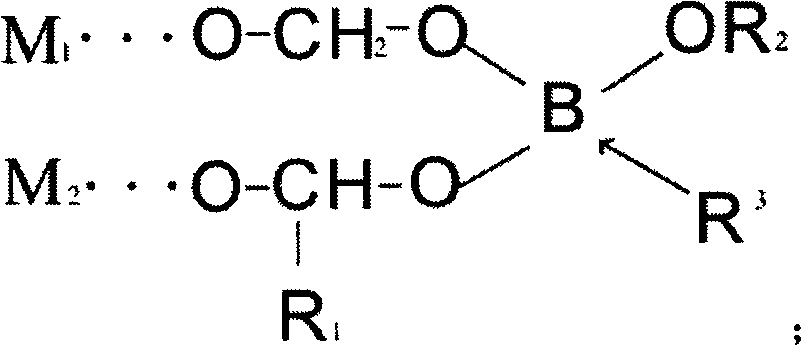

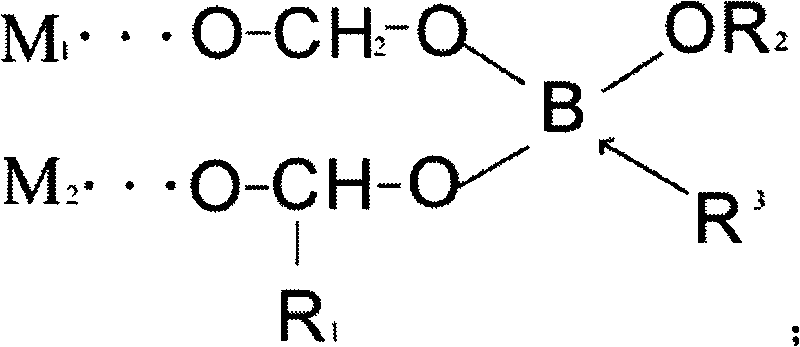

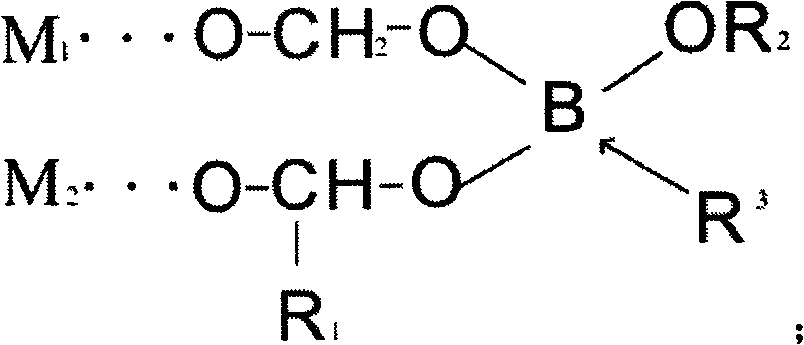

Method used

Image

Examples

Embodiment 1

[0019] A multifunctional rubber modifier for all-steel radial tires, which is prepared by the following steps:

[0020] First put glycerin with a set number of moles into a stainless steel reaction kettle, raise the temperature to 100°C, put in boric acid equal to the mole of glycerin, then seal the reaction kettle, heat up to 160°C under stirring conditions to react, and separate the small molecules through the oil-water separator. The by-products were removed, and the reaction was completed after the temperature in the kettle rose to 180° C. for 3-5 hours.

[0021] Then add PEG-1000 equimolar to glycerin, stir at 150 rpm, react for 3 hours under negative pressure of 300-500 mm Hg, extract and separate the by-products, and raise the temperature in the kettle to 220°C to complete the reaction. Then add diethanolamine in an equimolar amount to glycerin, maintain the temperature in the kettle at 180° C. for two hours, and the reaction ends; all the above processes are carried ou...

Embodiment 2

[0026] A kind of modified borate surfactant, it is made by following steps:

[0027] First put glycerin with a set number of moles into a stainless steel reaction kettle, raise the temperature to 60°C, put in boric acid equal to the mole of glycerin, then seal the reaction kettle, heat up to 120°C under stirring conditions to react, and separate the small molecules through the oil-water separator The by-products were removed, and the reaction was completed after the temperature in the kettle rose to 180° C. for 3-5 hours.

[0028] Then add equimolar C with glycerol 18 Fatty alcohol, stirred at 100 rpm, reacted for 5 hours under negative pressure of 300-500 mm Hg, extracted and separated the by-products, and raised the temperature in the kettle to 220°C to complete the reaction. Then add monoethanolamine in an equimolar amount to glycerol, maintain the temperature in the kettle at 160° C. for two hours, and the reaction ends; all the above-mentioned processes are carried out u...

Embodiment 3

[0033] A kind of modified borate surfactant, it is made by following steps:

[0034] First, put glycerin with a set number of moles into a stainless steel reaction kettle, raise the temperature to 80°C, put in boric acid equal to the mole of glycerin, then seal the reaction kettle, heat up to 140°C under stirring conditions to react, and separate the small molecules through the oil-water separator. The by-products were removed, and the reaction was completed after the temperature in the kettle rose to 180° C. for 3-5 hours.

[0035] Then add equimolar C with glycerol 18 Fatty acid, stirred at 120 rpm, reacted for 4 hours under negative pressure of 300-500 mm Hg, extracted and separated the by-products, and raised the temperature in the kettle to 220°C to complete the reaction. Then put in an equimolar amount of C with glycerol 18 Alkyl primary amines, maintain the temperature in the kettle at 170°C for two hours, and the reaction ends; all the above processes are carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com