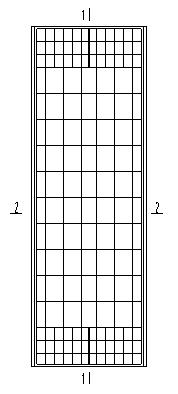

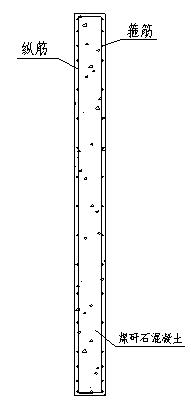

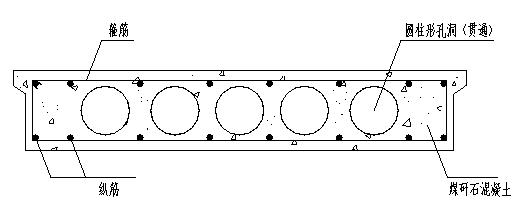

Prefabricated coal gangue concrete hollow shear wallboard

A technology of coal gangue concrete and shear wall, which is applied in the direction of building materials, building components, buildings, etc., to achieve the effect of reducing cost, simple production process and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention aims at the continuous improvement of the requirements for the anti-seismic ability of structures in our country, and the application of steel structures in multi-storey and high-rise buildings is becoming more and more extensive. Its anti-seismic performance has been greatly improved. The prefabricated coal gangue concrete hollow shear wall panel of the present invention can not only effectively improve the rigidity of the structure, but also not increase the self-weight of the structure too much. Compared with ordinary concrete shear wall panels, the new prefabricated gangue concrete hollow shear wall panels have their own characteristics. This is the requirement for the development of green buildings and the implementation of sustainable development strategies. The research on the new type of prefabricated coal gangue concrete hollow shear wall panel makes the frame-wall panel system formed by the new type of prefabricated coal gangue concrete h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com