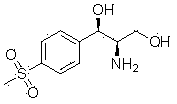

Method for synthesizing (1R, 2R)-1-p-methyl sulfone phenyl-2-amino-1,3-propanediol

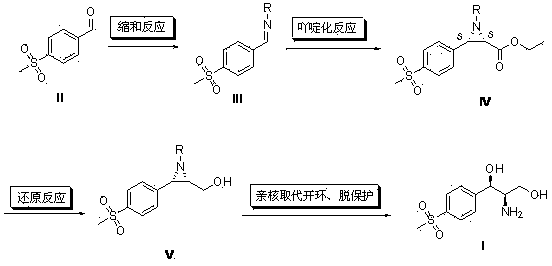

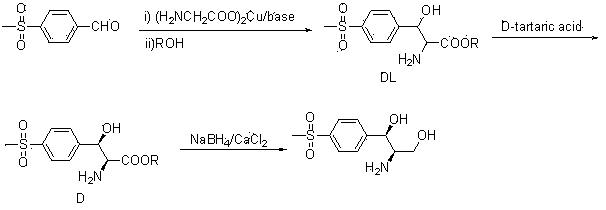

A technology for the synthesis of thiamphenylphenyl and its method, which is applied in the field of synthesis of 1-p-thiamphenylphenyl-2-amino-1,3-propanediol (I), and can solve the problems of lengthy steps and large dosage , to achieve the effect of short route, easy operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Put p-thymphenylbenzaldehyde (18.42 g, 0.10 mol), diphenylmethylamine (18.33 g, 0.10 mol), dichloroethane (200 mL), anhydrous magnesium sulfate (40.00 g) in a dry In the reaction bottle, react at room temperature for 12 hours. After the reaction was completed, filter and recover the solvent under reduced pressure to obtain a colorless oil, which was recrystallized with 95% ethanol and dried to obtain white crystals, namely compound (III) (9.60 g, 95%), mp: 139~140°C.

[0033] 1H NMR (CDCl 3 , ppm): δ=3.06 (s, 3H, CH 3 ), 5.67 (s, 1H, CH), 7.26 (m, 2H, ArH), 7.24-7.41 (m, 8H, ArH), 8.02 (m, 4H, ArH) 8.49 (s, 1H, NH).

[0034] ESI-MS: (m / z)=350.6 (M + ).

[0035] Two, (2 S , 3 S )-1-Benzhydryl-2-ethoxycarbonyl-3-sulfonylphenylacridine (IV).

Embodiment 21

[0036] Example 21 Under nitrogen protection, (2 R )-(+)-3,3'-diphenyl-[2,2'-binaphthyl]-1,1'-diol (4.39 g, 0.01mol), triphenyl borate (11.60 g, 0.04 mol) in a dry reaction flask, add 50 ml of toluene, heat to 80°C for 1 hour, recover the toluene under reduced pressure, keep it at 80°C for 0.5 hour under vacuum, cool to room temperature, dissolve with 50ml of anhydrous toluene, and Add to the suspension of compound (III) (69.8 g, 0.20 mol) in anhydrous toluene (700 ml), stir at room temperature for 5 minutes, cool down to -20°C, add ethyl diazoacetate (25.08 g, 0.22 mol) dropwise ), and continue to react for 6 hours. Then the solvent was recovered under reduced pressure, and the crude product was recrystallized twice with ethanol and water to obtain a colorless crystal which was compound (IV) (59.52 g, 68.3%), mp: 122~123°C, optical rotation [α] 25 D = -20.9° (1.05, CHCl 3 ), the ee value is 99.7%.

[0037] 1 H NMR (CDCl 3 , ppm): δ=1.00(t, 3H, J =7.0, CH 3 ), 2.77 (d...

Embodiment 22

[0039] Example 22 Under nitrogen protection, (3 R )-(+)-2,2'-diphenyl-[3,3'-diphenanthrene]-4,4'-diol (5.38 g, 0.01 mol), triphenyl borate (11.60 g, 0.04 mol ) in a dry reaction flask, add 50 ml of toluene, heat to 80 ° C for 1 hour, recover the solvent under reduced pressure, and keep it at 80 ° C for 0.5 hours under vacuum, cool to room temperature, dissolve with 50 ml of anhydrous toluene, and Add to the suspension of compound (III) (69.8 g, 0.20 mol) in anhydrous toluene (700 ml), stir at room temperature for 5 minutes, cool down to -20°C, add ethyl diazoacetate (25.08 g, 0.22 mol) dropwise ), and continue to react for 6 hours. Then the solvent was recovered under reduced pressure, and the crude product was recrystallized twice with ethanol and water to obtain a colorless crystal which was compound (IV) (58.20 g, 66.8%), melting point, optical rotation, 1 H NMR and MS consistent with Example 21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com