Method for producing furan ammonium salt by using furoic acid

A technology of furan ammonium salt and furan formic acid, which is applied in the direction of organic chemistry, can solve the problems of waste of alcohol and ammonia raw materials, unfavorable large-scale production, increase of production investment, etc., achieve good product quality, safe and reliable production process, and reduce resources wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

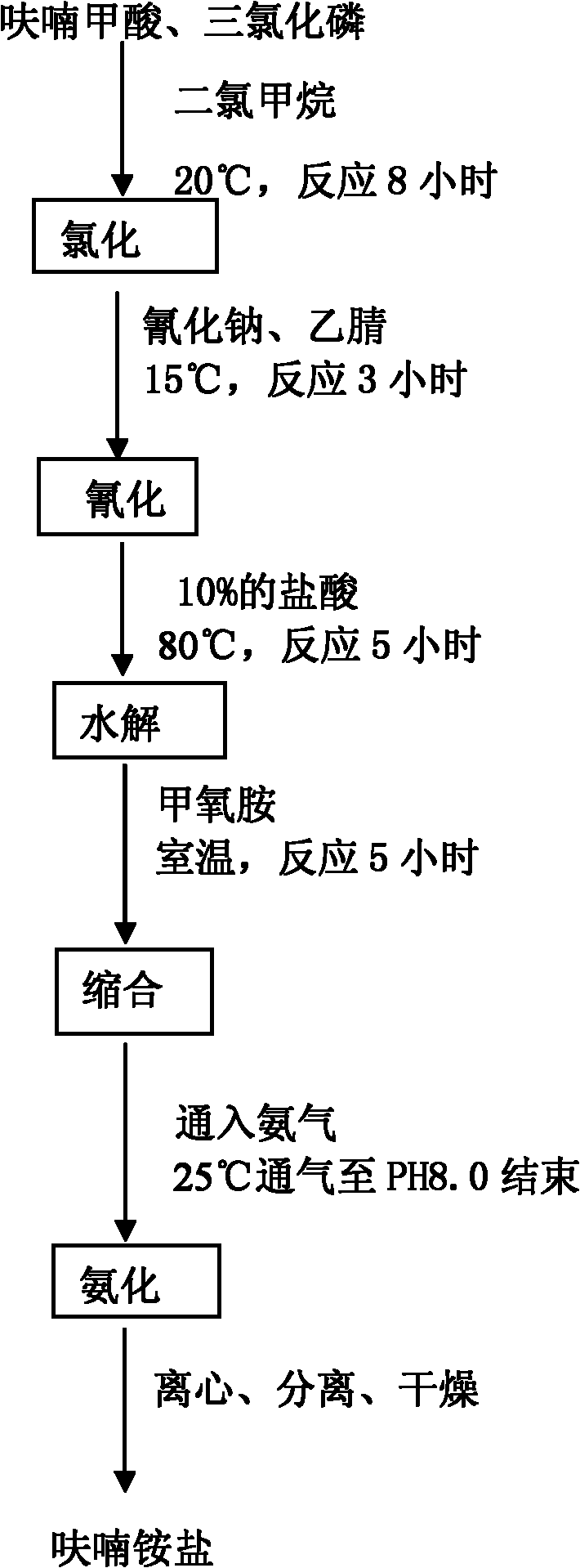

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] A kind of preparation method utilizing furan formic acid to produce furan ammonium salt, its steps are:

[0019] (1) Chlorination: 112kg of raw furan formic acid (outsourced) and 500kg of solvent dichloromethane are put into the glass-lined reactor, the stirring and heating system are turned on, and the temperature is controlled to 10 or 20 or 30 or 35 or 45 or 52 or 58 or 60 ℃, add chlorinating agent phosphorus trichloride 137.5kg (1000mol). The reaction was carried out for 5 or 6 or 7 or 8 or 9 or 10 hours, and the pressure was reduced to -0.08MPa to recover dichloromethane. Then at -0.095Mpa at 50°C, the product furoyl chloride was distilled off under reduced pressure to obtain about 125kg of the product.

[0020] (2) Cyanation: put 55kg (1000mol) of sodium cyanide in the reaction kettle and 120kg of acetonitrile, stir and cool down at -10 or -15 or -18 or -20℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com