Method for preparing animal blood plasma albumen powder

A plasma protein powder, livestock and poultry technology, applied in the field of livestock and poultry blood processing and utilization, can solve the problems of high ash content, poor quality, high energy consumption, etc., and achieve the effects of reducing energy consumption, improving recovery rate, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The original blood is fresh pig blood within 10 minutes of slaughtering and bleeding.

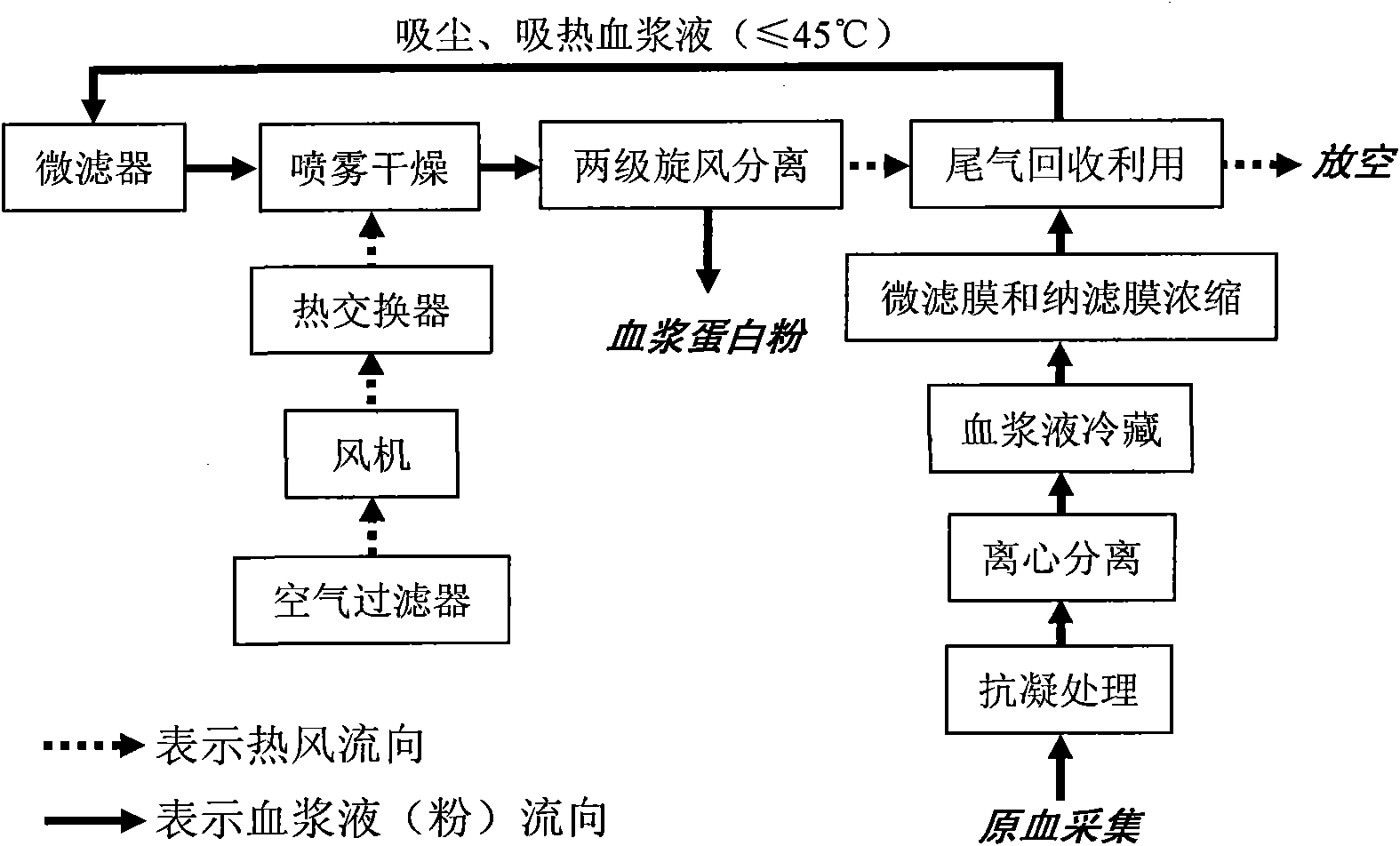

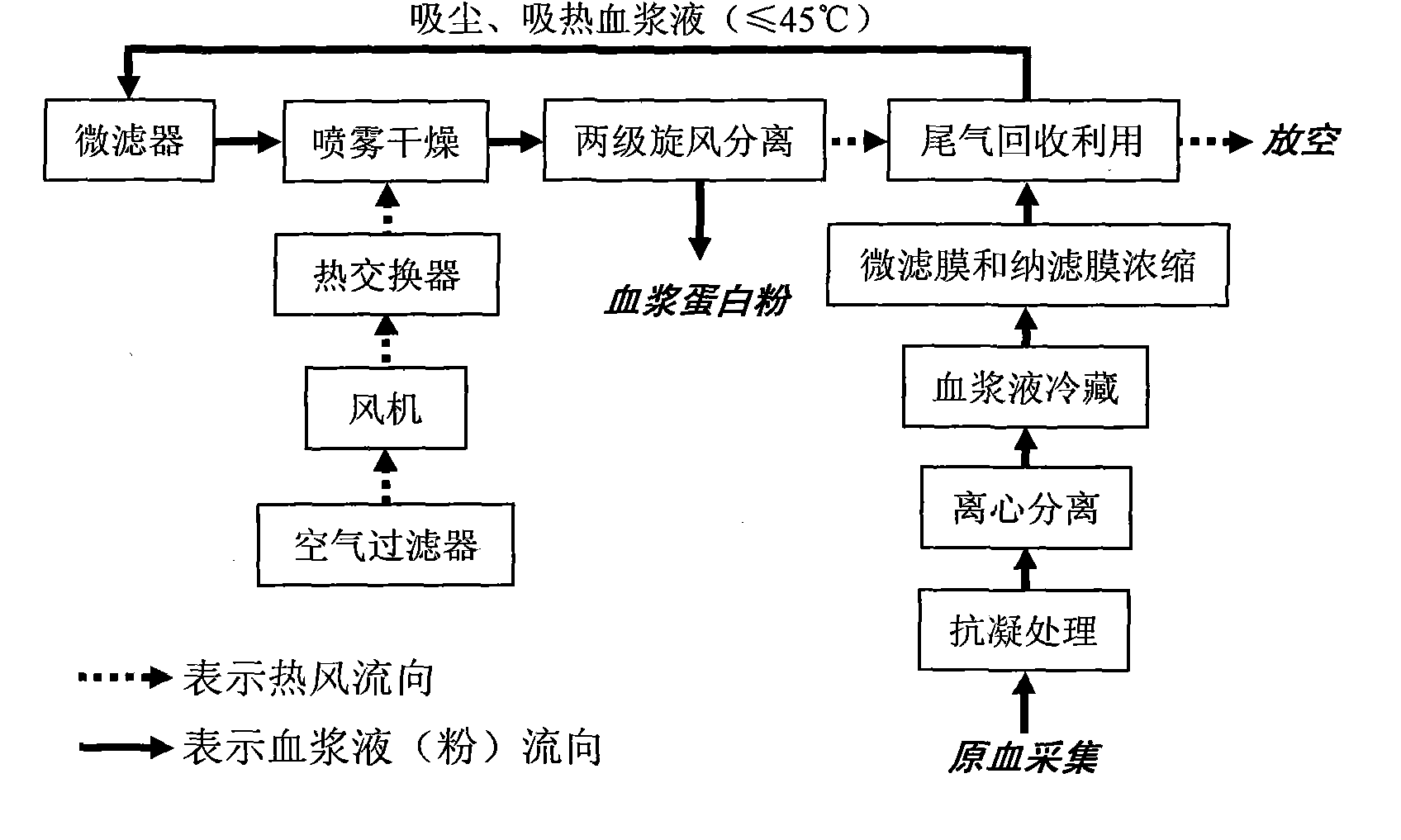

[0027] A kind of preparation method of the livestock and poultry plasma protein powder that takes fresh pig blood as raw material comprises the following steps (see figure 1 ):

[0028] (1) According to the mass concentration of 6-8% of sodium citrate, 3-4% of dipotassium EDTA and 3-4% of sodium hexametaphosphate, the compound anticoagulant aqueous solution (compound anticoagulant solution for short); The volume ratio of blood to compound anticoagulant aqueous solution is 1 / 19 (V / V), add compound anticoagulant solution to fresh pig blood, and stir and mix in time to realize anticoagulant treatment of pig blood; input the obtained anticoagulant pig blood Store in a sealed tank at 4-15°C for later use, and the tank storage time is ≤20h.

[0029] (2) Under the environment of 4-15°C, the anticoagulated pig blood is pumped into a tubular centrifuge to separate blood cell fluid and plasm...

Embodiment 2

[0034] Raw materials: fresh cattle blood slaughtered and bled within 10 minutes.

[0035] Other conditions are with embodiment 1. The product is bovine blood plasma protein powder.

Embodiment 3

[0037] Raw materials: fresh chicken blood slaughtered and bled within 10 minutes.

[0038] Method: except that the spray-drying air inlet temperature is 200°C-220°C, and the exhaust air temperature is 100-110°C, other conditions are the same as in Example 1. The product is chicken blood plasma protein powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com