Method for preparing polycarboxylate water reducing agent

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of preparation of polycarboxylate water reducing agent, can solve the problem that it is difficult to take into account plasticity preservation and high water reducing rate, cannot achieve the effect of normal water reducing agent, and cannot meet the requirements of construction. and other problems, to achieve the effect of solving the easy discoloration of light, reducing the damage rate and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

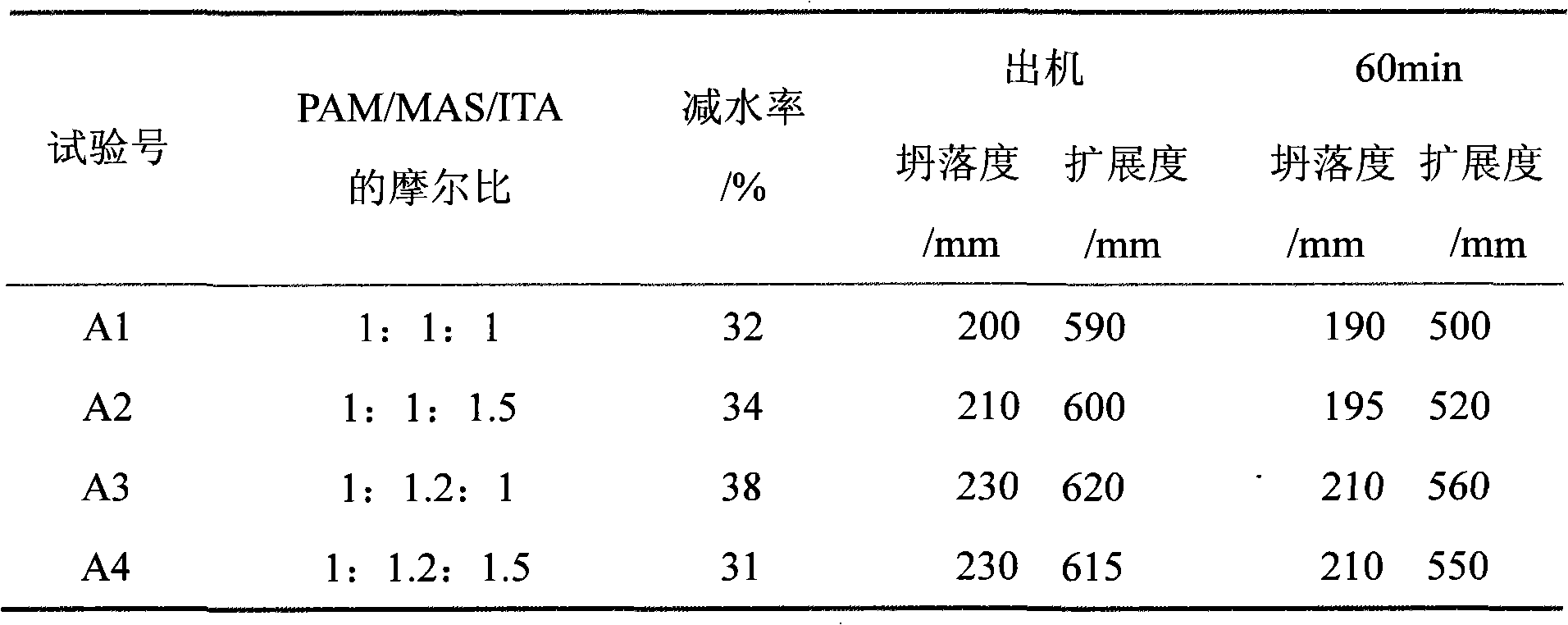

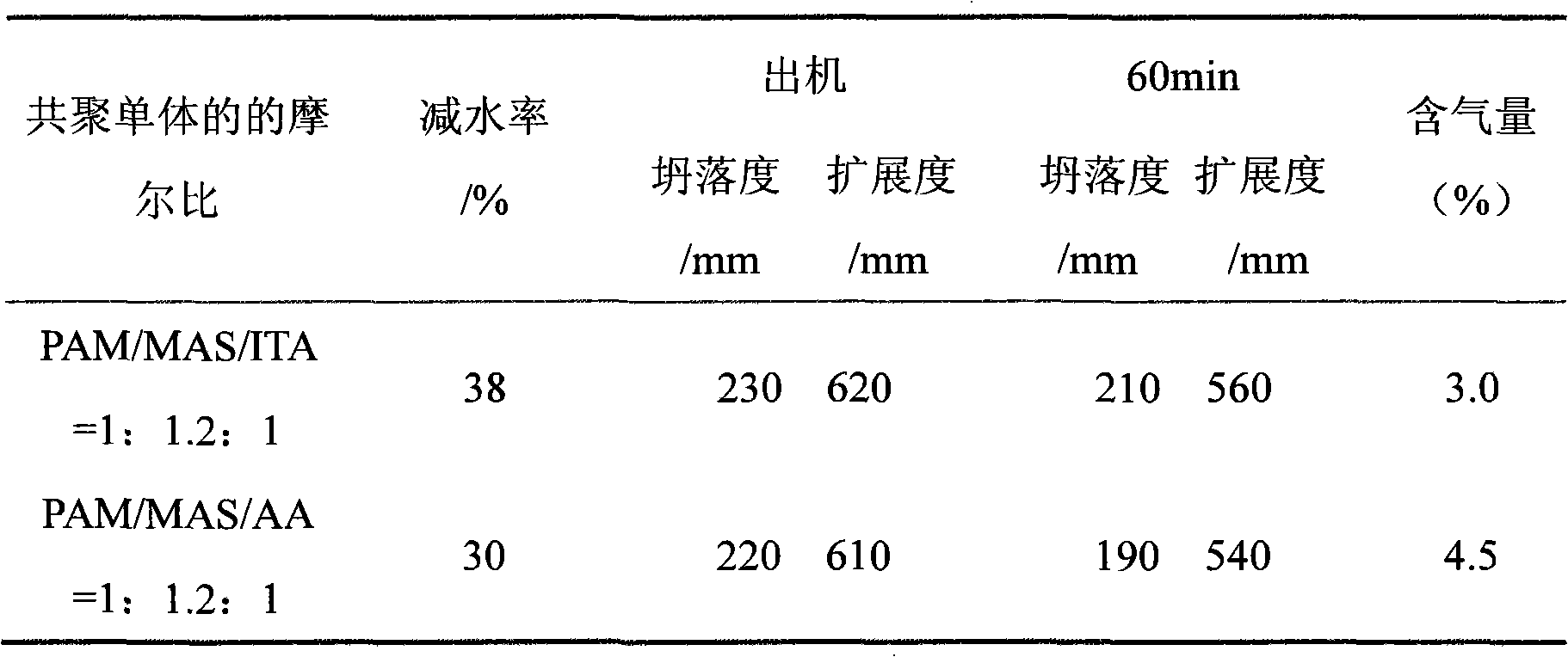

[0034] Terpolymer polycarboxylate superplasticizer PAM, MAS, ITA monomer molar ratio is 1: (1-1.2): (1-1.5), the following PAM, MAS, ITA molar ratio is 1:1:1 Taking the implementation method of synthesizing polycarboxylate superplasticizer as an example, discuss the influence of the ratio of polymerized monomers on the performance of concrete;

[0035] (1) Synthesis of PAM: put 12000kg MPEG-1200), 1176kg MAH, 20.664kg catalyst PTSA into the reactor and stir evenly, control the molar ratio of polyethylene glycol monomethyl ether, maleic anhydride, toluenesulfonic acid to be 1: 1.2 : 0.012, at normal pressure, temperature is 90 ℃ under the condition of esterification reaction 8h, take away moisture by inert gas as water-carrying agent, esterification rate is 90%, obtain 11682kg polyethylene glycol monomethyl ether maleic acid activity macromonomer PAM;

[0036] (2), step (1) 11682kg polyethylene glycol monomethyl ether maleic acid reactive macromonomer PAM and 1422kg sodium met...

Embodiment 2

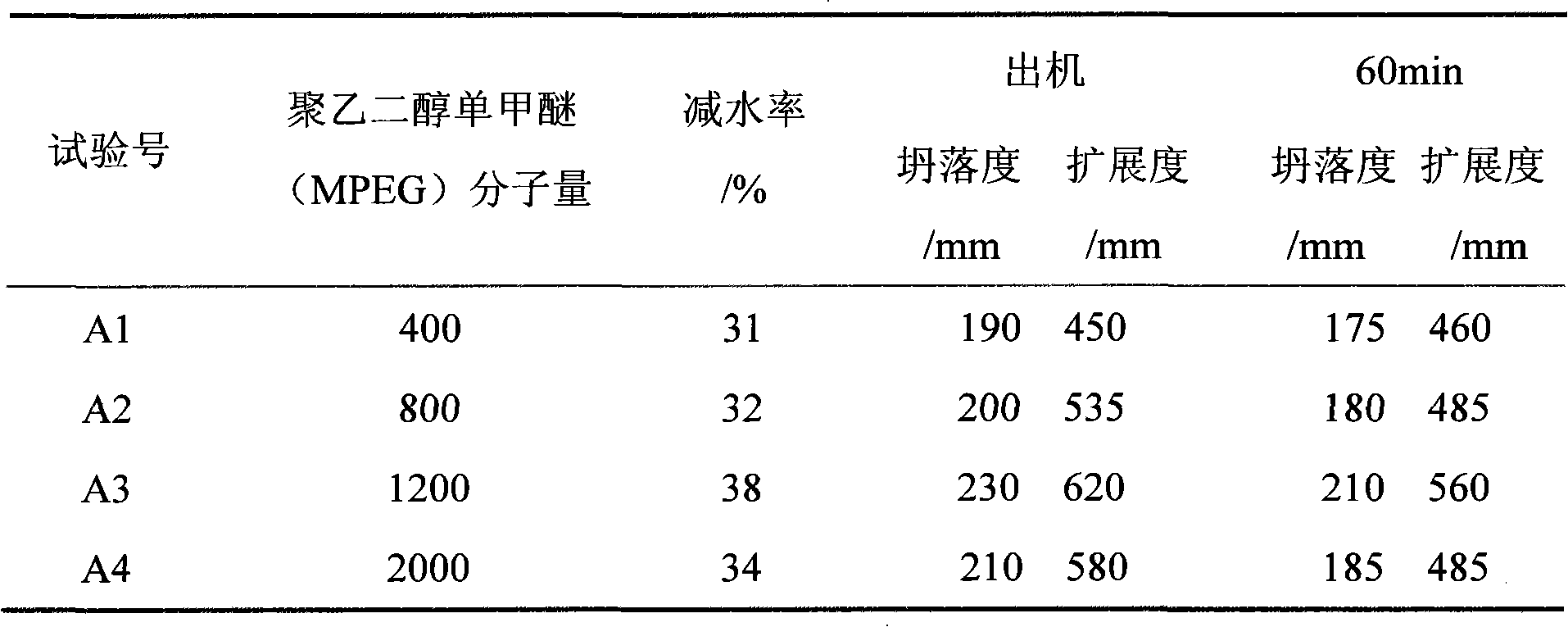

[0043] The molar ratio of the terpolymer polycarboxylate water reducer PAM, MAS, and ITA monomers is controlled as 1:1.2:1, and the influence of the molecular weight of MPEG on the performance of concrete mixed with polycarboxylate water reducer is discussed; the following uses MPEG The molecule is 1200 cases of synthetic polycarboxylate superplasticizer, other data can be analogized:

[0044] (1) Synthesis of PAM: 12000kg MPEG-1200, 1176kg MAH, and 20.664kg catalyst PTSA were dropped into the reactor and stirred evenly, and the molar ratio of polyethylene glycol monomethyl ether, maleic anhydride, and toluenesulfonic acid was controlled to be 1: 1.2:0.012, under normal pressure and temperature at 90°C, esterification reaction took place for 8 hours, and the moisture was taken away by inert gas as a water-carrying agent. The esterification rate was 90%, and 11682kg of polyethylene glycol monomethyl ether maleic acid was obtained. active macromonomer PAM;,

[0045] (2) step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com