Solid fermentation method for producing salt-tolerant cellulase by using oceanic Aspergillus niger

A marine Aspergillus niger and cellulase technology, applied in microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve problems such as low utilization efficiency and utilization limitations, and achieve high equipment utilization, simple cultivation process, Effects that are easy to control and magnify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

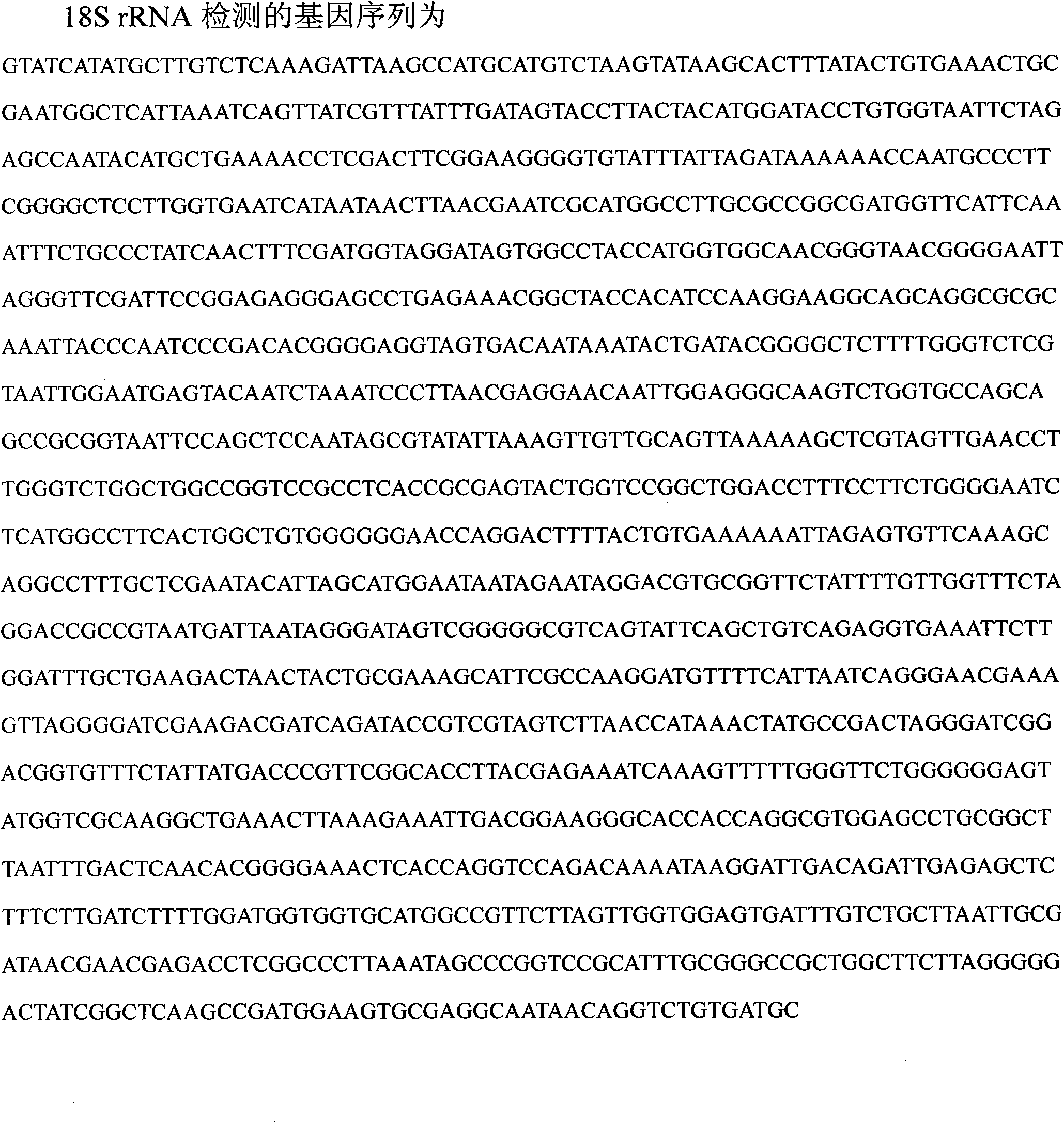

[0035] 1) A marine Aspergillus niger was screened from the soil at a depth of 10m off the coast of the East China Sea;

[0036] 2) Marine Aspergillus niger was inoculated on PDA medium, cultured at 40°C for 90 hours to obtain slant spores, which were stored at 4°C;

[0037] 3) The slant spores were inoculated in PDA-1 medium, and cultured at 40° C. for 90 hours to obtain activated spores;

[0038] 4) Put 60g of eggplant bottle slant culture medium into a 250ml eggplant bottle and compact it into a slant, seal the mouth of the bottle with 8 layers of gauze to obtain the slant of the eggplant bottle, inoculate the activated spores on the slant of the eggplant bottle, culture at 42°C for 74 hours, and obtain the expanded culture eggplant bottle slant spores;

[0039] 5) Put 400ml of artificial seawater into a 500ml volumetric flask, put it into a sterilizer, and sterilize it at 121°C for 20 minutes to obtain sterilized artificial seawater, and dilute the slanted spores of the eg...

Embodiment 2

[0047] 1) A marine Aspergillus niger was screened from the soil at a depth of 10m off the coast of the East China Sea;

[0048] 2) Marine Aspergillus niger was inoculated on PDA medium, cultured at 40°C for 90 hours to obtain slant spores, which were stored at 4°C;

[0049] 3) The slant spores were inoculated in PDA-1 medium, and cultured at 40° C. for 90 hours to obtain activated spores;

[0050] 4) Put 60g of eggplant bottle slant culture medium into a 250ml eggplant bottle and compact it into a slant, seal the mouth of the bottle with 8 layers of gauze to obtain the slant of the eggplant bottle, inoculate the activated spores on the slant of the eggplant bottle, culture at 42°C for 74 hours, and obtain the expanded culture eggplant bottle slant spores;

[0051] 5) Put 400ml of artificial seawater into a 500ml volumetric flask, put it into a sterilizer, and sterilize it at 121°C for 20 minutes to obtain sterilized artificial seawater, and dilute the slanted spores of the eg...

Embodiment 3

[0057] 1) A marine Aspergillus niger was screened from the soil at a depth of 10m off the coast of the East China Sea;

[0058] 2) Marine Aspergillus niger was inoculated on PDA medium, cultured at 40°C for 90 hours to obtain slant spores, which were stored at 4°C;

[0059] 3) The slant spores were inoculated in PDA-1 medium, and cultured at 40° C. for 90 hours to obtain activated spores;

[0060] 4) Put 60g of eggplant bottle slant culture medium into a 250ml eggplant bottle and compact it into a slant, seal the mouth of the bottle with 8 layers of gauze to obtain the slant of the eggplant bottle, inoculate the activated spores on the slant of the eggplant bottle, culture at 42°C for 74 hours, and obtain the expanded culture eggplant bottle slant spores;

[0061] 5) Put 400ml of artificial seawater into a 500ml volumetric flask, put it into a sterilizer, and sterilize it at 121°C for 20 minutes to obtain sterilized artificial seawater, and dilute the slanted spores of the eg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com