Oxyfuel combusting boiler system and a method of generating power by using the boiler system

A boiler and fuel technology, applied in the field of oxy-fuel combustion boiler systems, can solve the problems of increased production costs and reduced net power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

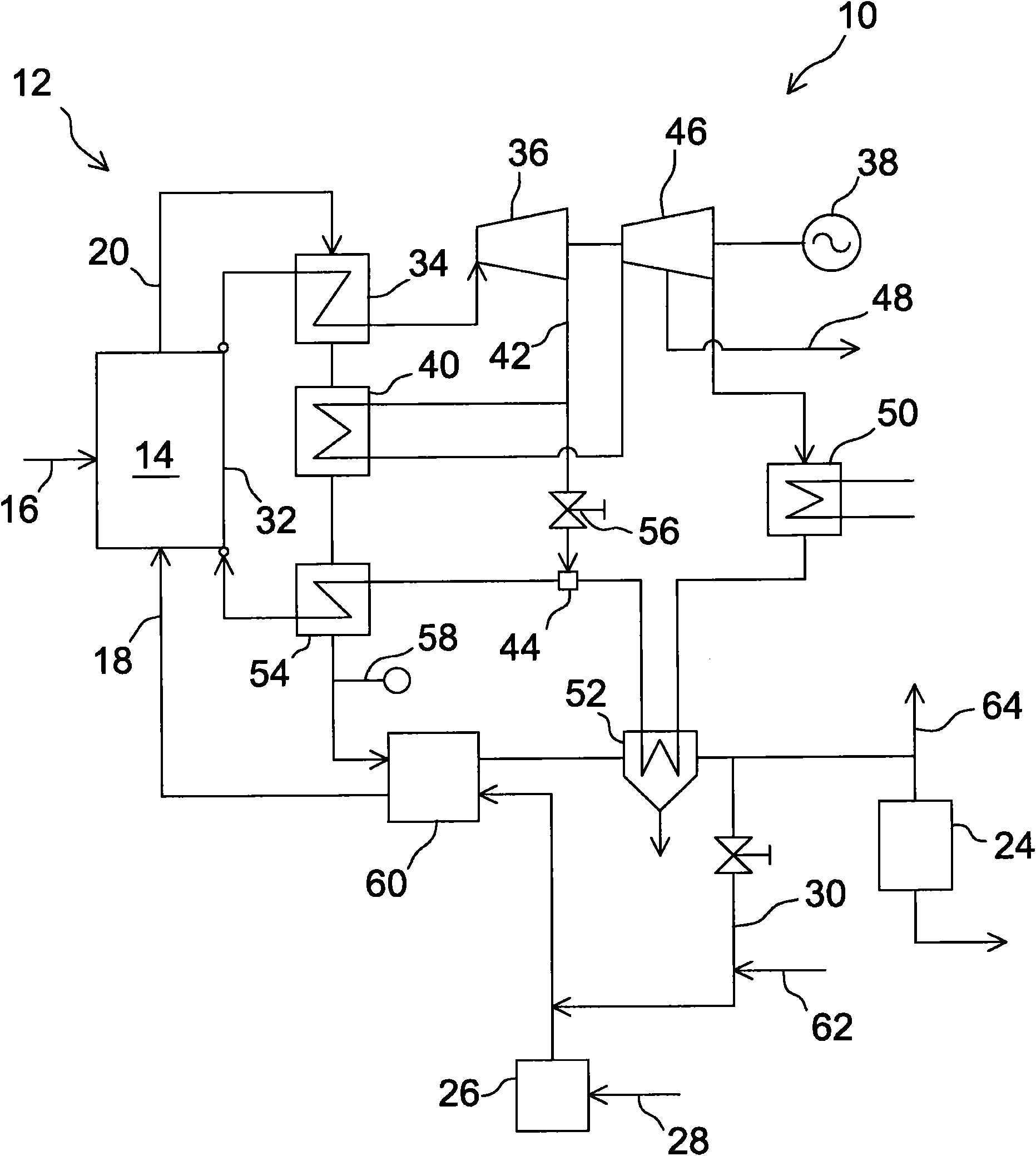

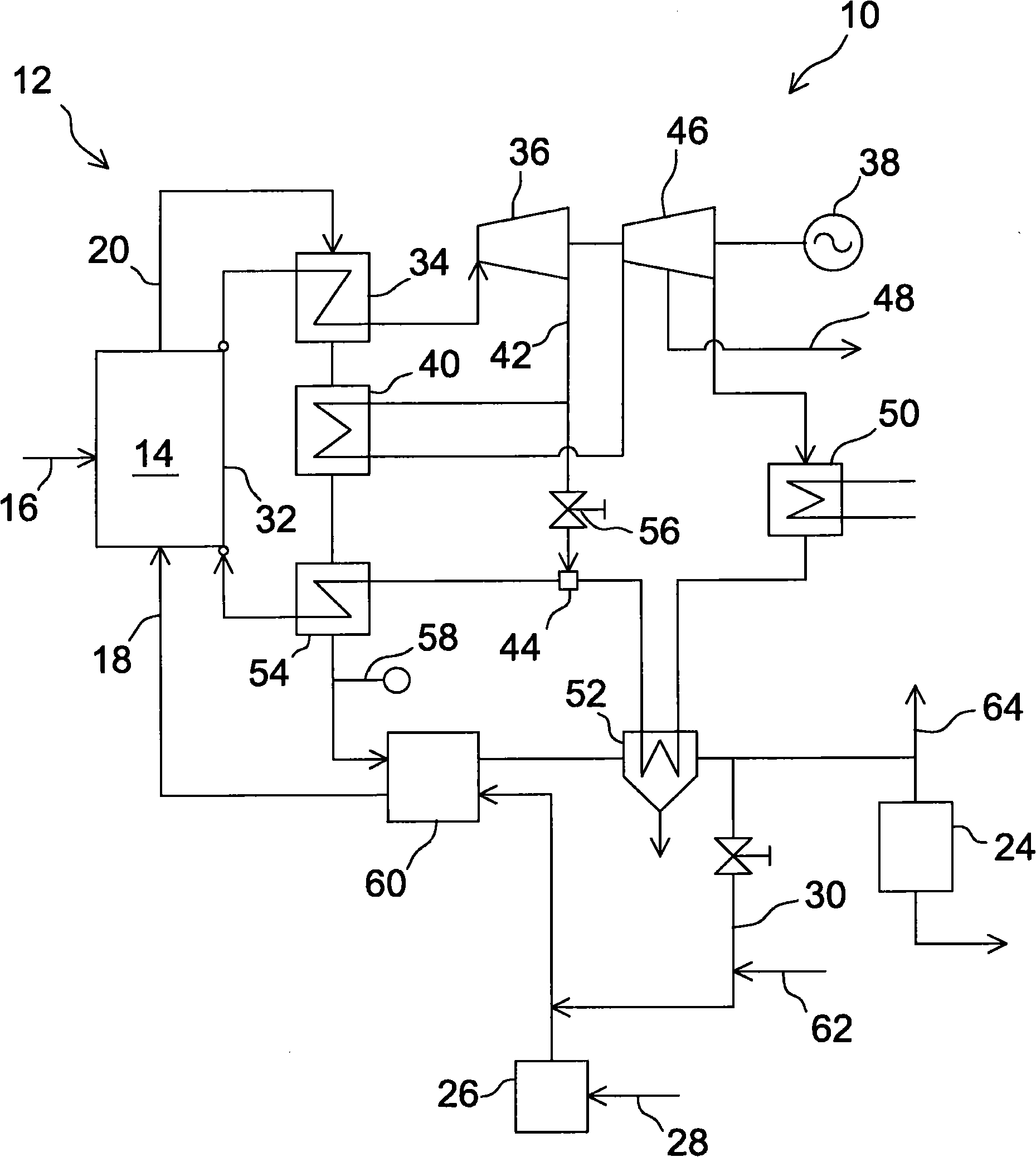

[0024] figure 1 A schematic diagram of an oxy-fired boiler system 10 according to a preferred embodiment of the present invention is shown. The boiler system 10 includes a boiler 12 which may be, for example, a pulverized coal (PC) boiler or a circulating fluidized bed (CFB) boiler. Boiler 12 comprises: conventional fuel feeding device 16, such as fuel supply pipe; The device for introducing oxidant gas into the furnace 14 of boiler, such as gas supply line 18; The exhaust gas produced by the combustion of oxygen in the gas is discharged. The details and type of some elements of boiler 12, such as fuel feed 16 and oxidant gas feed 18, will of course depend on the type of boiler. However, such details as burners, coal mills, means for separately feeding primary and secondary oxidant gases are not important to the present invention and are therefore discussed in figure 1 not shown in

[0025] The oxy-fired boiler system 10 is advantageously retrofitted from an existing air-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com