Method of determining particle size distribution of fine particles contained in metallic material

A metal material, particle size distribution technology, applied in the direction of material separation, particle size analysis, material analysis through optical means, etc., can solve the problems of incorrectness, comparison of pulse intensity, inability to apply luminescence analysis method, etc., and achieve accurate particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] Next, examples of the present invention will be described. However, the present invention is not limited to the conditions employed in Examples.

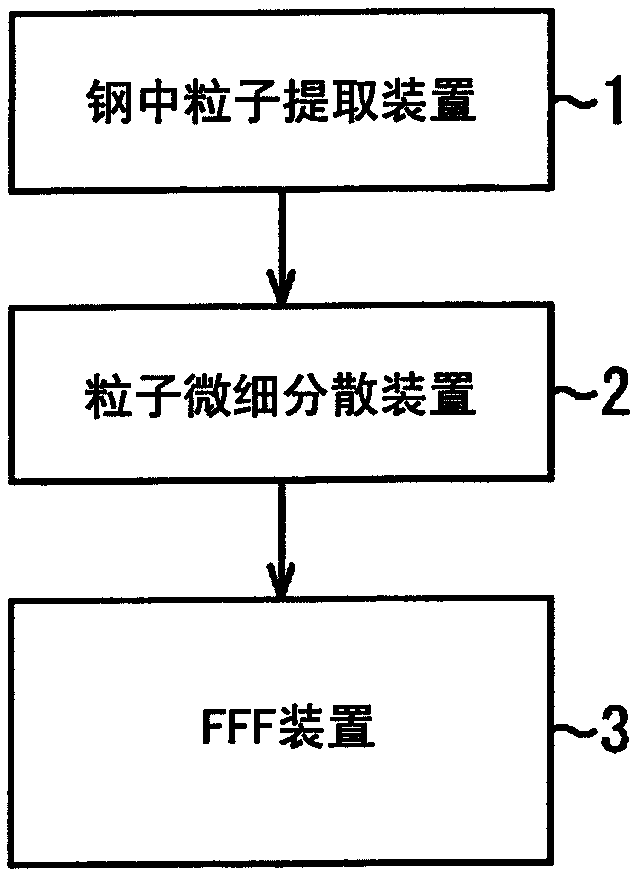

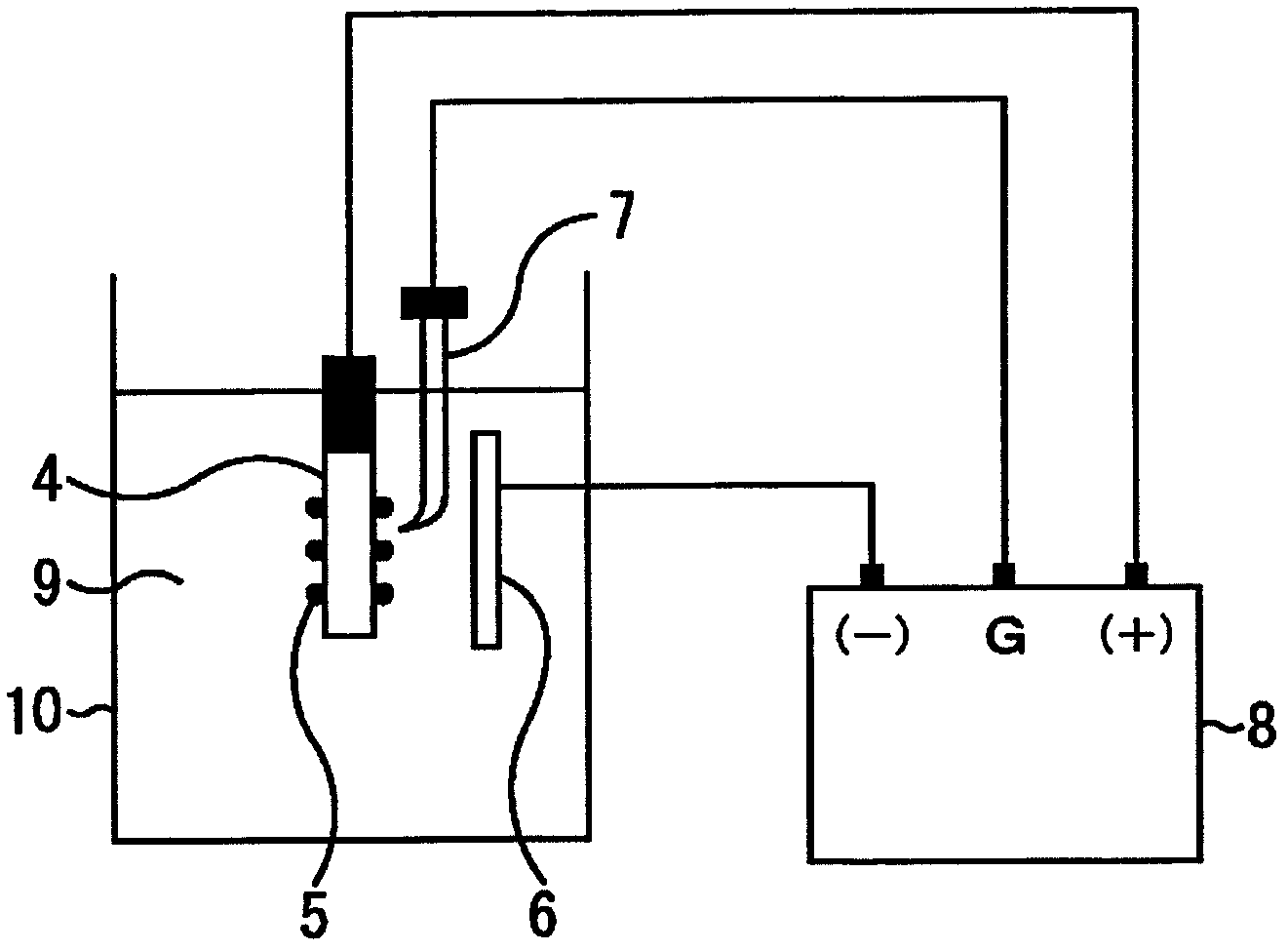

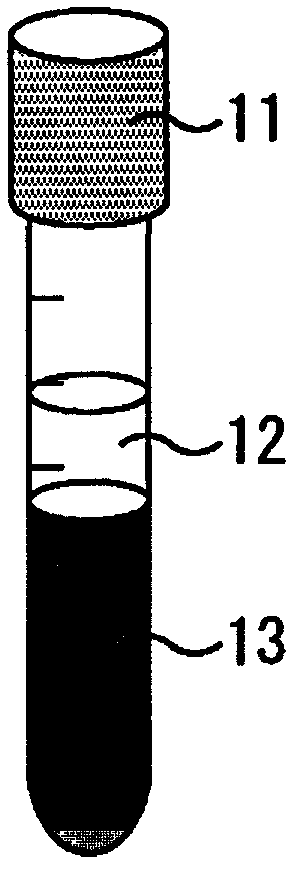

[0092] according to figure 1 In the flow shown, after the fine particles in the iron and steel material are extracted and dispersed in the solution, the size and number density are measured by the fine particle analysis method of this embodiment with the FFF apparatus.

[0093] High Si-based steel samples (Si: 3% by mass, Mn: 0.1% by mass, S: 0.03% by mass, Al: 0.03% by mass, N: 0.01% by mass) were processed into a size of 20mm×40mm×0.3mm, and passed Chemical polishing removes oxide films such as iron oxide scale on the surface to expose the metal layer. At this time, regarding the high-Si-based steel samples, samples were taken from steel materials produced under the conditions that the heating temperature in the manufacturing process was specified as a normal temperature (1000°C) and a high temperature (1100°C) about 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com