High branch cationic starch for papermaking wet end and preparation method thereof

A cationic starch and cationic etherification technology, which is applied in papermaking, textiles, papermaking, paper, etc., can solve the problems that the product type and quality cannot fully meet the market demand, so as to maintain the same strength of paper strength, improve performance, and improve paper quality. The effect of force strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

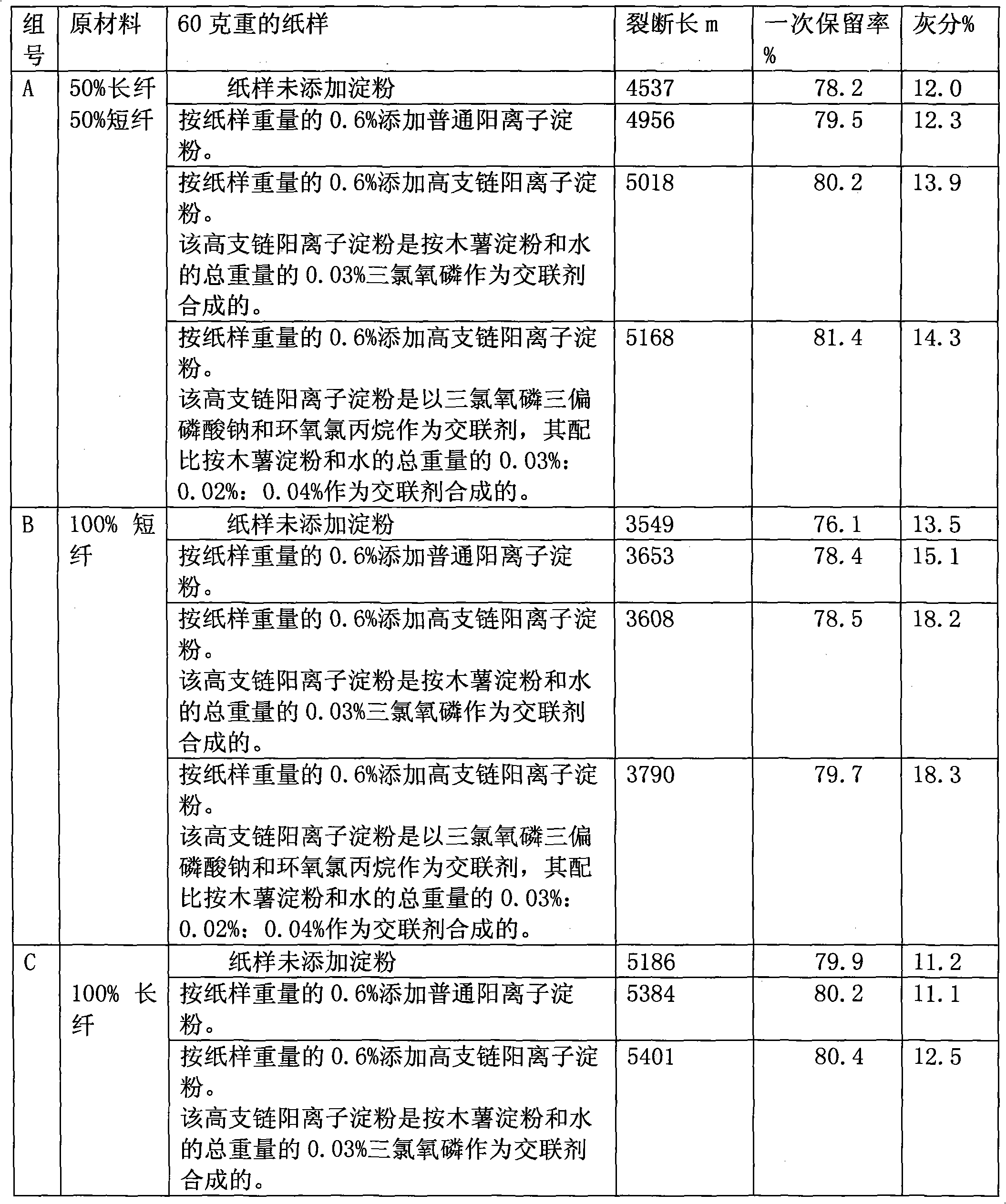

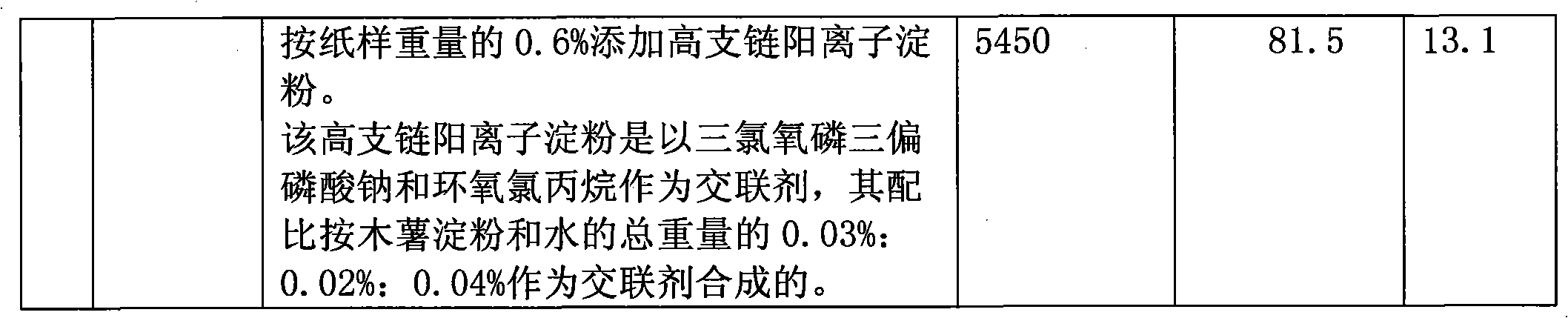

Examples

Embodiment 1

[0028] Embodiment 1, the preparation method of high amylopectin cationic starch for wet end of papermaking is characterized in that: it is made of the following raw materials in parts by weight: 30-60 parts of tapioca starch and 40-70 parts of water go through cationic etherification step and crosslinking reaction step and drying and crushing step to obtain;

[0029] The cationic etherification step is as follows: stir tapioca starch and water evenly, then heat up to 25-40°C, add sodium hydroxide to adjust the pH value to 10.8-11.2, and add 6%-8% of the total weight of tapioca starch and water 3-Chloro-2-hydroxypropyltrimethylammonium chloride, react at 36-40°C for 12-20 hours, and maintain the pH at 10.8-11.2 during the reaction;

[0030] The cross-linking reaction step is: lower the temperature to 30°C, add phosphorus oxychloride at 0.03%-0.2% of the total weight of tapioca starch and water, maintain the pH at 10.8-11.2 during the reaction, maintain a constant temperature of...

Embodiment 2

[0032] Embodiment 2, high amylopectin cationic starch for papermaking wet end and preparation method thereof, wherein: made from the following raw materials in parts by weight: 30 parts of tapioca starch and 50 parts of water go through cationic etherification step and crosslinking reaction step and drying and milling Obtained by crushing steps;

[0033] The cationic etherification step is as follows: stir tapioca starch and water evenly and then heat up to 25°C, add sodium hydroxide to adjust the pH value to 10.8, add 3-chloro-2-hydroxyl to 6% of the total weight of tapioca starch and water Propyltrimethylammonium chloride, reacted at 36°C for 12 hours, and maintained the pH at 10.8 during the reaction;

[0034]The cross-linking reaction step is: lower the temperature to 30°C, add phosphorus oxychloride according to 0.2% of the total weight of tapioca starch and water, maintain the pH at 10.8-11.2 during the reaction, maintain a constant temperature of 30°C, and react 1 under...

Embodiment 3

[0036] Embodiment 3, the preparation method of highly amylopectin cationic starch for the wet end of papermaking, wherein: it is made of the following raw materials in parts by weight: 50 parts of tapioca starch and 50 parts of water go through cationic etherification step, crosslinking reaction step and drying and crushing step to obtain;

[0037] The cationic etherification step is as follows: stir tapioca starch and water evenly, then heat up to 30°C, add sodium hydroxide to adjust the pH value to 11, add 3-chloro-2-hydroxyl to 7% of the total weight of tapioca starch and water Propyltrimethylammonium chloride, reacted at 38°C for 17 hours, and maintained the pH at 11 during the reaction;

[0038] The cross-linking reaction step is as follows: cool down to 30°C, add phosphorus oxychloride at 0.03% of the total weight of tapioca starch and water, maintain pH at 11 during the reaction, maintain a constant temperature of 30°C, and react for 1 hour under stirring. All the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com