Functional filling capable of improving wear-resistant property of plastic and rubber and preparation method thereof

A technology of functional fillers and wear resistance, applied in the field of functional fillers and their preparation, can solve the problems of not meeting the requirements of high wear resistance, limited effect of wear resistance modification, high product cost, etc., and achieve excellent scratch resistance Performance, low production cost, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

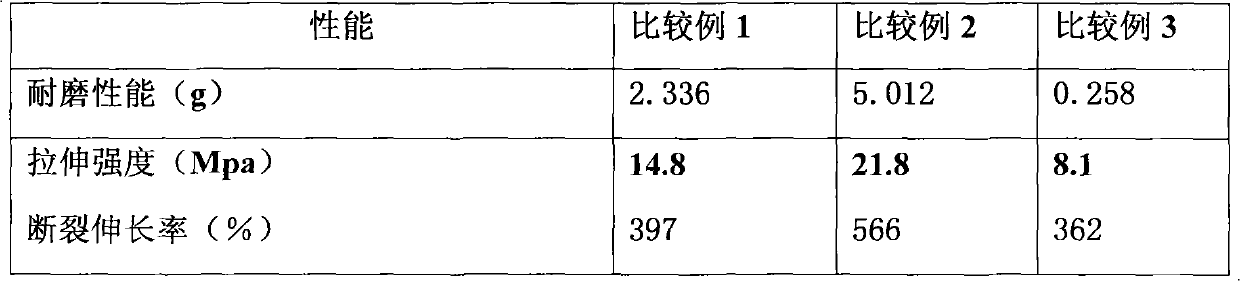

Examples

Embodiment 1

[0013] Example 1: Preparation of a functional filler A for soft and hard PVC.

[0014] Weigh the silicate compound particles according to a certain amount, put them into a high-speed stirrer, and then add stearic acid accounting for 1.0% of the total mass of functional fillers + titanate accounting for 1.0% of the total mass of functional fillers as activation Coupling agent, stirring speed 1200-1500 rev / min, stirring for 10-15 minutes. The stirring temperature was 100°C.

Embodiment 2

[0015] Example 2: Preparation of a functional filler B for polypropylene.

[0016] Weigh the silicate compound particles according to a certain amount, put them into a high-speed stirrer, and then add KH-560 silane coupling agent accounting for 1.0% of the total mass of functional fillers, stirring at a speed of 1200-1500 rpm, stirring 10-15 minutes. The stirring temperature is 90°C.

Embodiment 3

[0017] Embodiment 3: Preparation of a functional filler C for nitrile rubber.

[0018] Weigh the silicate compound particles according to a certain amount, put them into a high-speed stirrer, and then add stearic acid accounting for 1.0% of the total mass of functional fillers + aluminum-titanium coupling agent accounting for 1.5% of the total mass of functional fillers (commercially available product), stirring speed 1200~1500 rpm, stirring for 10~15 minutes. The stirring temperature was 110°C.

[0019] Changes in the amount of the coupling agent within the scope of the present invention will not affect its effect, and the preparation method is the same.

[0020] The following examples are specific implementations of the application of three functional fillers. Each part number is a mass part number.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com