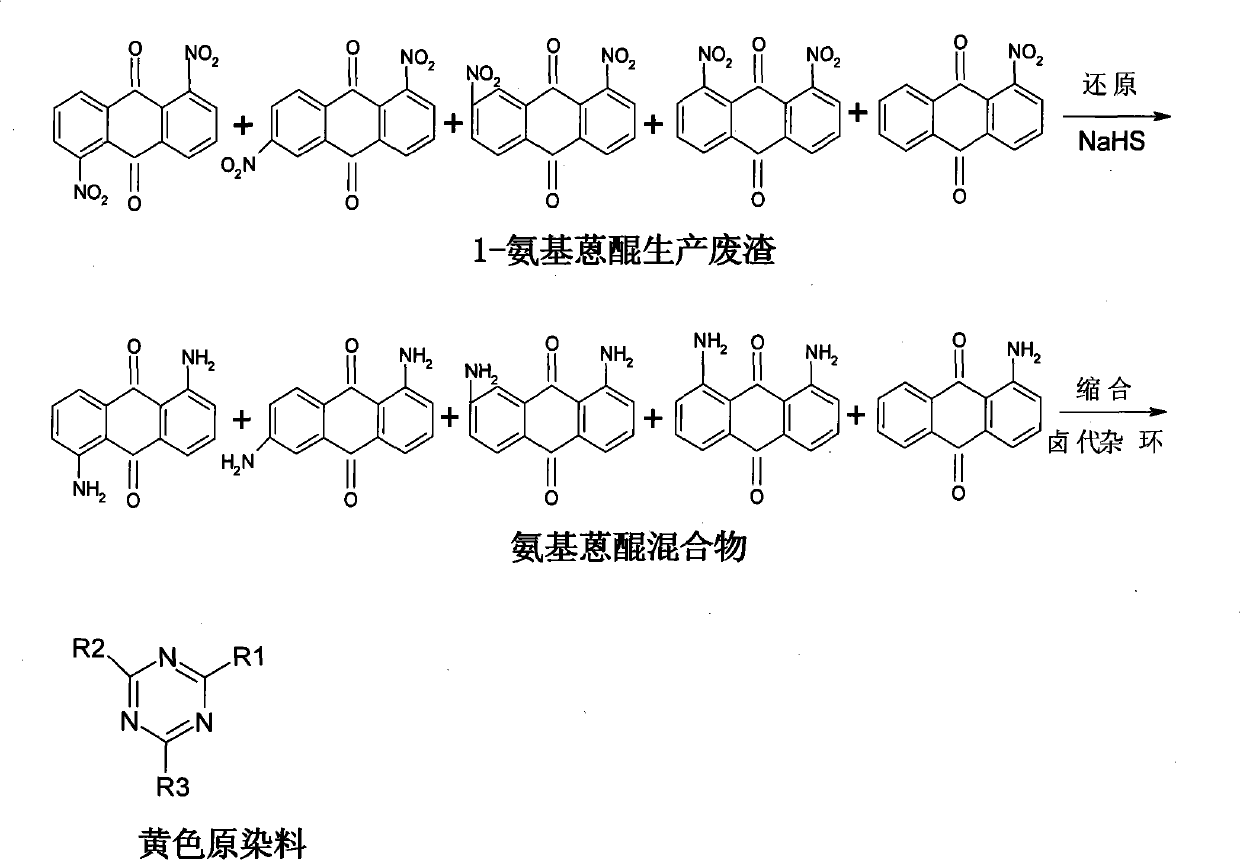

Method for manufacturing yellow dye by utilizing 1-amino anthraquinone production waste residues

An aminoanthraquinone and waste residue technology, applied in anthracene dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of waste of organic components, inability to fully utilize waste residues, generation of waste residues, etc., and achieve improved utilization, obvious economic benefits, The effect of price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] ① Preparation of reducing agent sodium hydrosulfide aqueous solution

[0042] In a 500ml beaker, add 200ml of hot water above 85°C and 20g of sodium hydrosulfide, stir until completely dissolved, filter, collect the filtrate sodium hydrosulfide aqueous solution, and set aside;

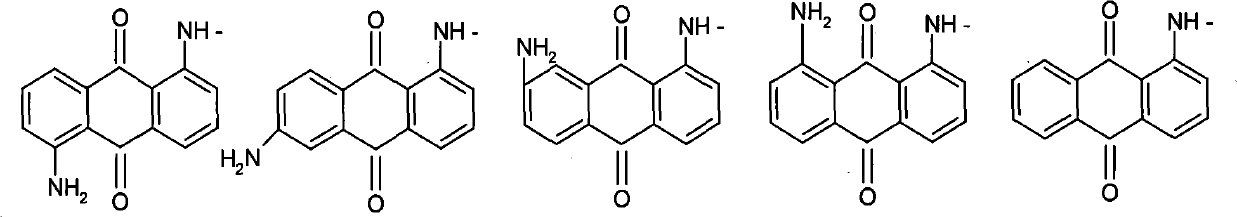

[0043] ② reduction

[0044] In a 500ml four-neck flask, add the sodium hydrosulfide aqueous solution prepared in step ①, add 60g of dried 1-aminoanthraquinone production waste residue under stirring, heat to 95°C for reduction reaction, and keep it warm under stirring at this temperature After 5 hours to reduce the various nitroanthraquinones contained in the production waste residue to the corresponding aminoanthraquinones, lower the temperature to 60 ° C and filter, wash the filter cake to neutrality, and then dry it to obtain the reduced raw material aminoanthraquinone mixture (34-36g ), the weight ratio of production waste residue and sodium hydrosulfide used for the reduction reaction is 6...

Embodiment 2

[0050] Step 1. sodium hydrosulfide consumption is 50g, step 2. the weight ratio of production waste residue and sodium hydrosulfide is 60: 50 (1: 0.83), and all the other are identical with embodiment 1;

[0051] ③Condensation

[0052] In a 250ml four-neck flask, add 180g of medium-chlorobenzene and 20g of the reducing material obtained in step ② under stirring, and after stirring for 0.5 hours, add 4g of halogenated heterocyclic compound cyanuric fluoride and heat it up to 55°C, add Sodium bicarbonate 2g, heat preservation at 95~98°C for 4 hours to conduct condensation reaction, measure the amino value of the material at 23wt%, the condensation reaction can be completed, cool down to 80°C, add hot water to carry out steam distillation of the material, collect and condense The distilled product is to be treated, the remaining material is suction filtered, the obtained filter cake is washed with hot water until neutral, and dried to obtain a yellow primary dye (22g). The appear...

Embodiment 3

[0055] Step 1. sodium hydrosulfide consumption is 40g, step 2. the weight ratio of production waste residue and sodium hydrosulfide is 60: 40 (1: 0.67), and all the other are identical with embodiment 1;

[0056] ③Condensation

[0057] In a 250ml four-neck flask, add 200g of o-dichlorobenzene as a medium and 20g of the reducing material obtained in step ② under stirring. After stirring for 0.5 hours, add 7g of halogenated heterocyclic compound cyanuric chloride and heat it up to 55°C. Sodium bicarbonate 3g, heat preservation at 98~100°C for 4 hours to carry out condensation reaction, measure the amino value of the material at 28wt%, the condensation reaction can be completed, lower the temperature to 80°C, add hot water to carry out steam distillation of the material, collect and condense The distilled product is to be treated, the remaining material is suction filtered, the obtained filter cake is washed with hot water until neutral, and dried to obtain a yellow primary dye (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com