Method for preparing load-type noble metal nanometer catalyst by solvent-free microwave-assisted pyrolysis method

A microwave-assisted, precious metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as cumbersome steps, high cost of solvents, and unfavorable industrialization , to achieve the effects of reduced dosage, environmental friendliness, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 0.0316g triruthenium dodecacarbonyl (Ru: 15wt.%) and 0.1g untreated carbon nanotubes, mix them, grind them in an agate mortar for 20min, and put them into a fluidized reaction tube, purging with argon 2h, microwave 800W heating 1min, 3min, 5min, 7min, 15min respectively, the argon flow rate in the reaction is: 100mL / min, cool to room temperature in the argon atmosphere, about 12h, can get the carbon nanotube supported ruthenium catalyst (Ru / CNTs).

[0020] Sample serial number

Embodiment 2

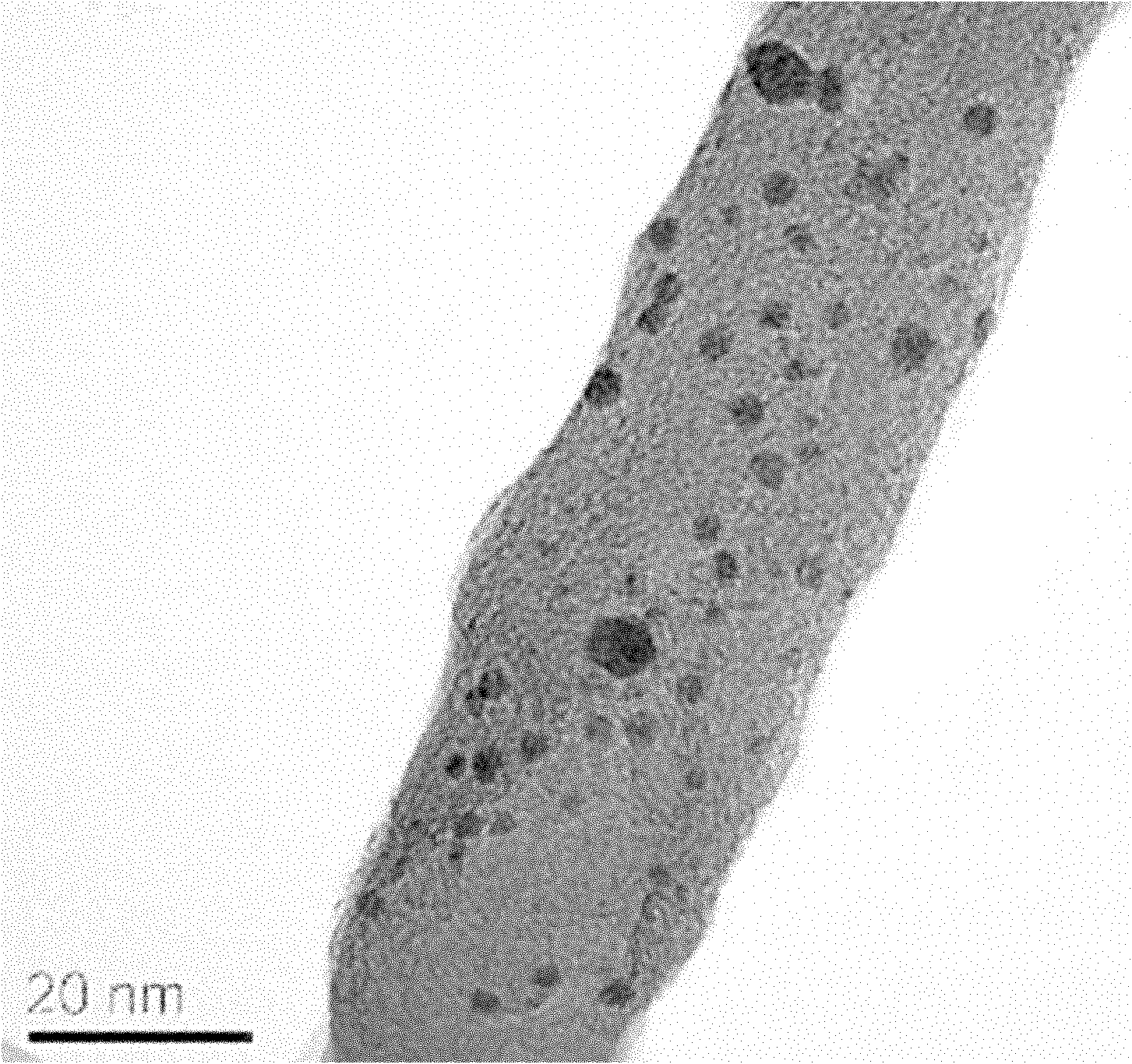

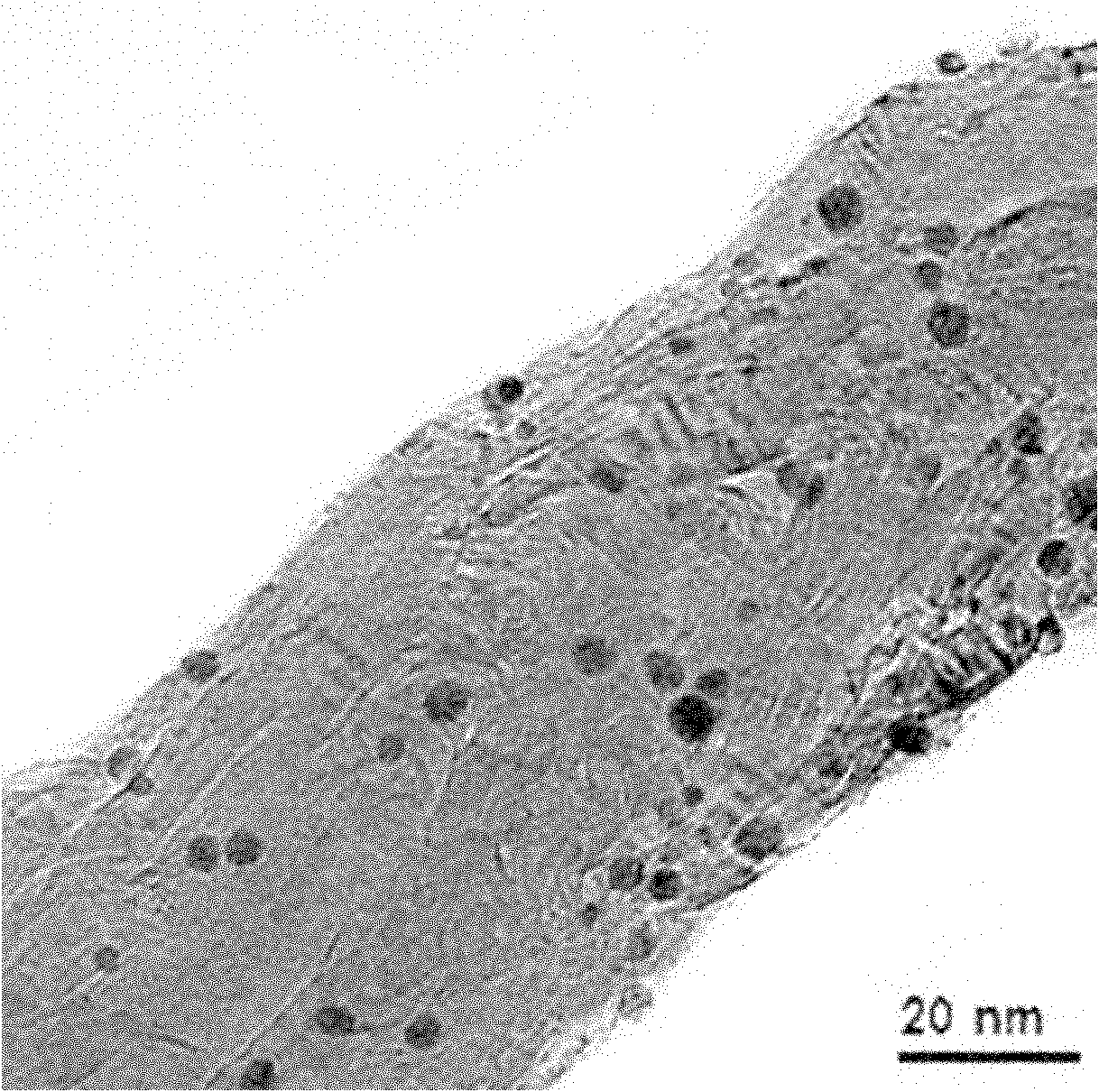

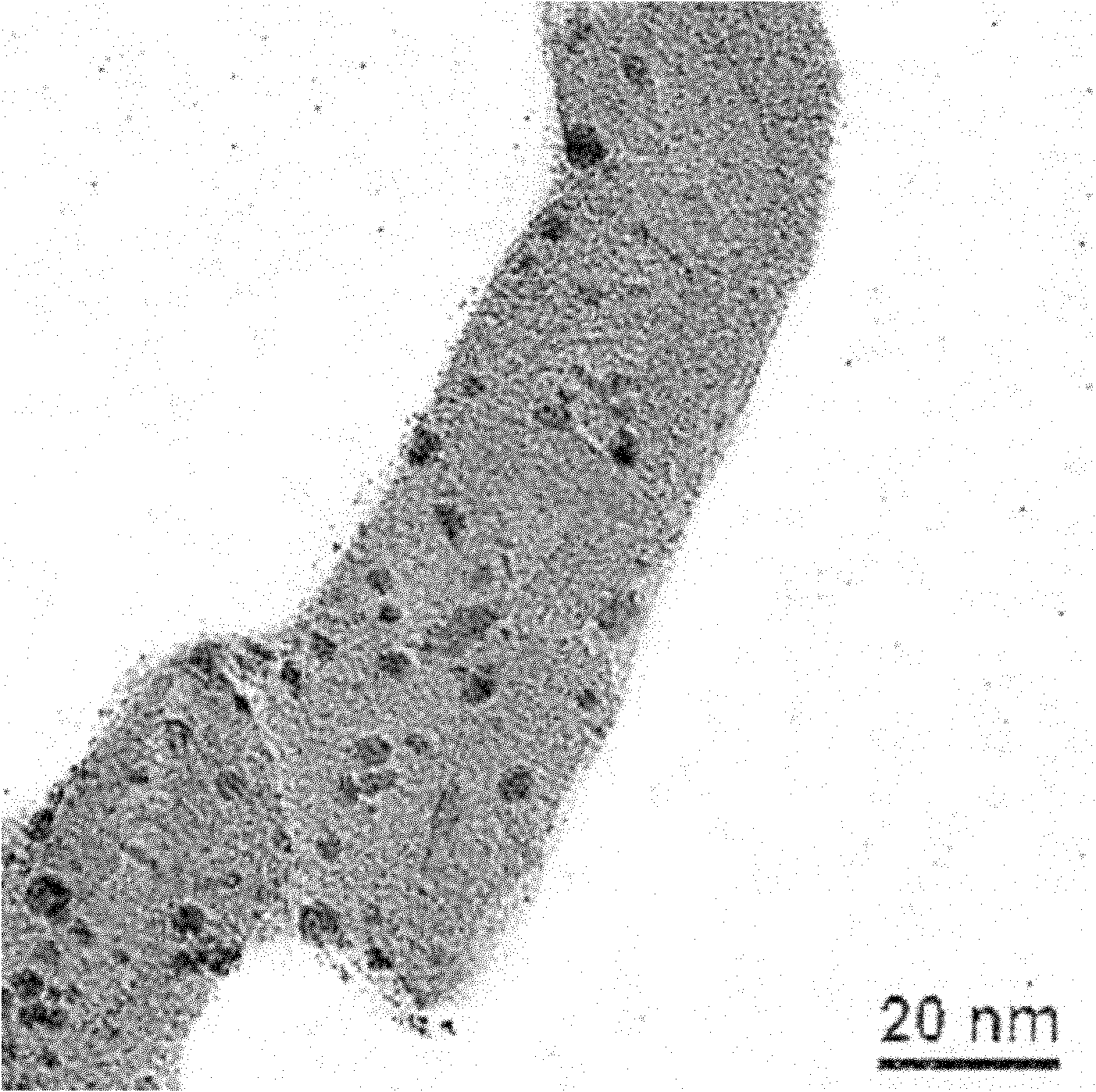

[0022] Weigh 0.0316g (15wt.%), 0.0210g (10wt.%), 0.0105g (5wt.%) triruthenium dodecacarbonyl and 0.1g untreated carbon nanotubes respectively, mix and grind in an agate mortar After 20 minutes, put it into a fluidized reaction tube, purge it with argon for 2 hours, and heat it with a microwave at 800W for 5 minutes. Supported ruthenium catalysts (Ru / CNTs). The XRD spectrum of the obtained Ru / CNTs is as follows figure 2 shown. It was identified as metal ruthenium by X-ray powder diffraction. The transmission electron micrographs of the obtained samples are shown in figure 1 , 2 , 3.

[0023] Sample serial number

Embodiment 3

[0025] Measure 60mL of deionized water, then measure 60mL of concentrated nitric acid, add the concentrated nitric acid into the water and stir. Measure 180mL of concentrated sulfuric acid, make the volume ratio of concentrated sulfuric acid, concentrated nitric acid and water 3:1:1, and mix the three evenly. Weigh 3 g of carbon nanotubes and add them into the mixed acid. After ultrasonication for 5 min, reflux at 120° C. and keep the temperature constant for 4 h. Cool to room temperature, filter and wash to pH = 6, dry at 120°C for 3 hours, and store for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com