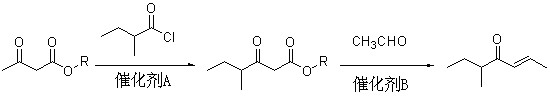

Method for preparing 5-methyl-2-hepten-4-one

A technology of heptene and methyl, which is applied in the field of preparation of 5-methyl-2-hepten-4-one, can solve the problems of difficult industrial production, cumbersome operation, and large pollution, and achieve easy industrial production and simple operation , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

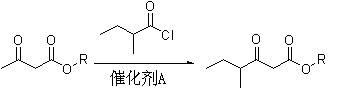

[0036] (1), the preparation of ethyl 2-methylbutyroacetate

[0037] In a 2L four-neck flask equipped with mechanical stirring, dropping funnel and thermometer, add 77.8g (1.05mol) of calcium hydroxide and 500ml of dichloromethane. Under rapid stirring, 130 g (1.0 mol) of ethyl acetoacetate was slowly added dropwise, the temperature was controlled at 20-30°C, and the dropwise addition time was about 20 minutes. After the dropwise addition, continue to stir for 0.5 hours, then add 138.6g (1.15mol) of 2-methylbutyryl chloride dropwise to it, maintain the temperature at 30-35°C, drop the time for about 1.5 hours, and then continue at 40°C Stir for 2 hours;

[0038] Dissolve 56.2g (1.05mol) of ammonium chloride in 350ml of water, add it to the above reactant at 30°C, stir for half an hour, add an appropriate amount of ammonia water to adjust the pH value of the solution to 9, and then add it at 30-35 Continue to stir for 3 hours at ℃ to obtain a solution containing ethyl 2-methyl...

Embodiment 2

[0045] (1), the preparation of ethyl 2-methylbutyroacetate

[0046] In a 2L four-neck flask equipped with mechanical stirring, dropping funnel and thermometer, add 77.8g (1.05mol) of calcium hydroxide and 500ml of dichloromethane. Under rapid stirring, 130 g (1.0 mol) of ethyl acetoacetate was slowly added dropwise, the temperature was controlled at 20-30°C, and the dropwise addition time was about 20 minutes. After the dropwise addition, continue to stir for 0.5 hours, then add 132.5g (1.10mol) of 2-methylbutyryl chloride dropwise to it, maintain the temperature at 30-35°C, drop the time for about 1.5 hours, and then continue at 40°C Stir for 2 hours;

[0047] Dissolve 56.2g (1.05mol) of ammonium chloride in 350ml of water, add it to the above reactant at 30°C, stir for half an hour, add an appropriate amount of ammonia water to adjust the pH value of the solution to 9, and then add it at 30-35 Continue to stir for 3 hours at ℃ to obtain a solution containing ethyl 2-methyl...

Embodiment 3

[0054] (1), the preparation of ethyl 2-methylbutyroacetate

[0055] In a 2L four-neck flask equipped with mechanical stirring, dropping funnel and thermometer, add 77.8g (1.05mol) of calcium hydroxide and 500ml of dichloromethane. Under rapid stirring, 130 g (1.0 mol) of ethyl acetoacetate was slowly added dropwise, the temperature was controlled at 20-30°C, and the dropwise addition time was about 20 minutes. After the dropwise addition, continue to stir for 0.5 hours, then add 126.5g (1.05mol) of 2-methylbutyryl chloride dropwise to it, maintain the temperature at 30-35°C, drop the time for about 1.5 hours, and then continue at 40°C Stir for 2 hours;

[0056] Dissolve 56.2g (1.05mol) of ammonium chloride in 350ml of water, add it to the above reactant at 30°C, stir for half an hour, add an appropriate amount of ammonia water to adjust the pH value of the solution to 9, and then add it at 30-35 Continue to stir for 3 hours at ℃ to obtain a solution containing ethyl 2-methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com