Food steamer type multi-purpose solid anaerobic fermentation device

An anaerobic fermentation and cage technology, which is applied in specific-purpose bioreactors/fermenters, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problem of low device utilization, increased power consumption, and reduced yield and other problems, to achieve the effect of simplifying labor, facilitating heat dissipation, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

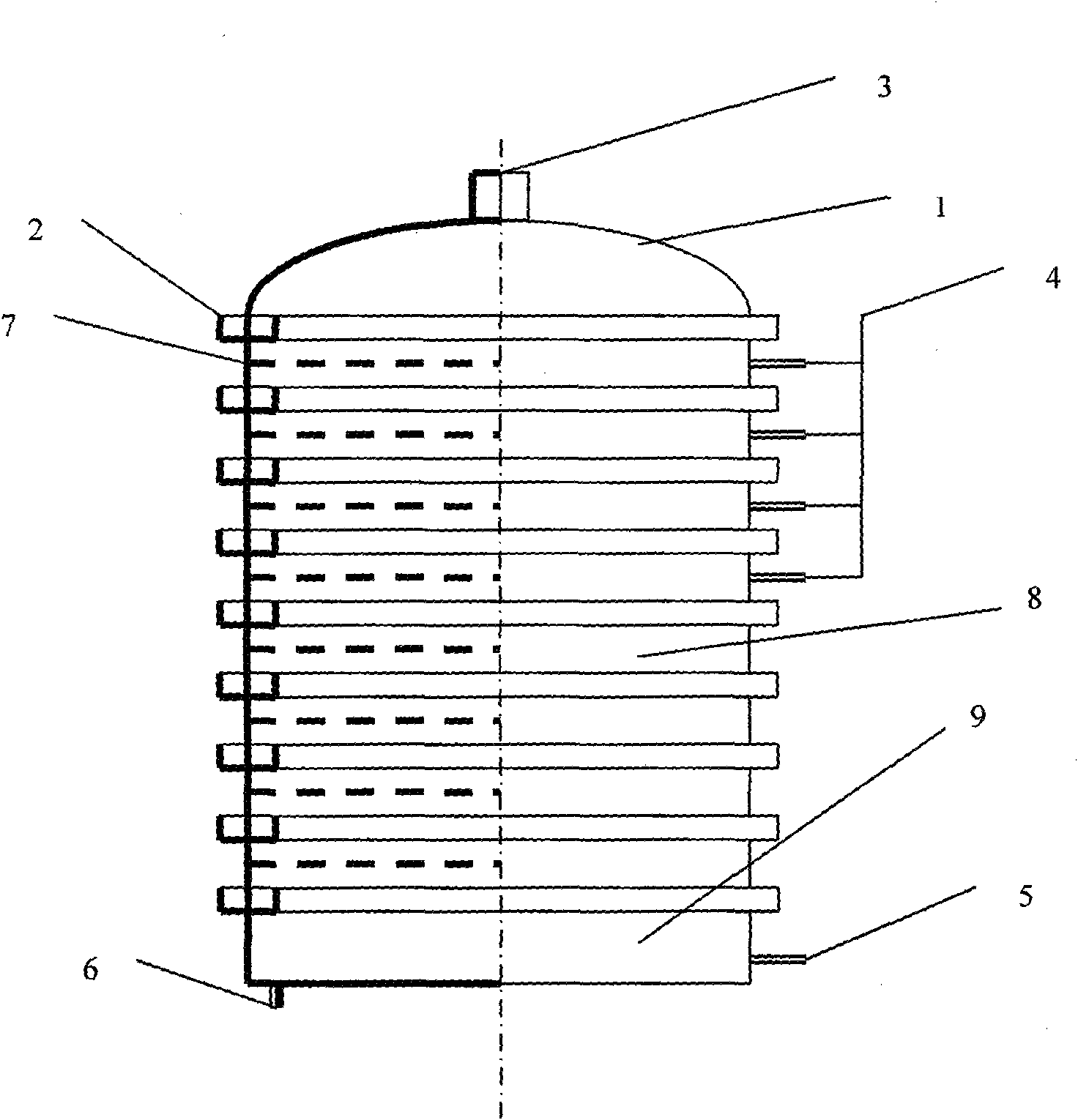

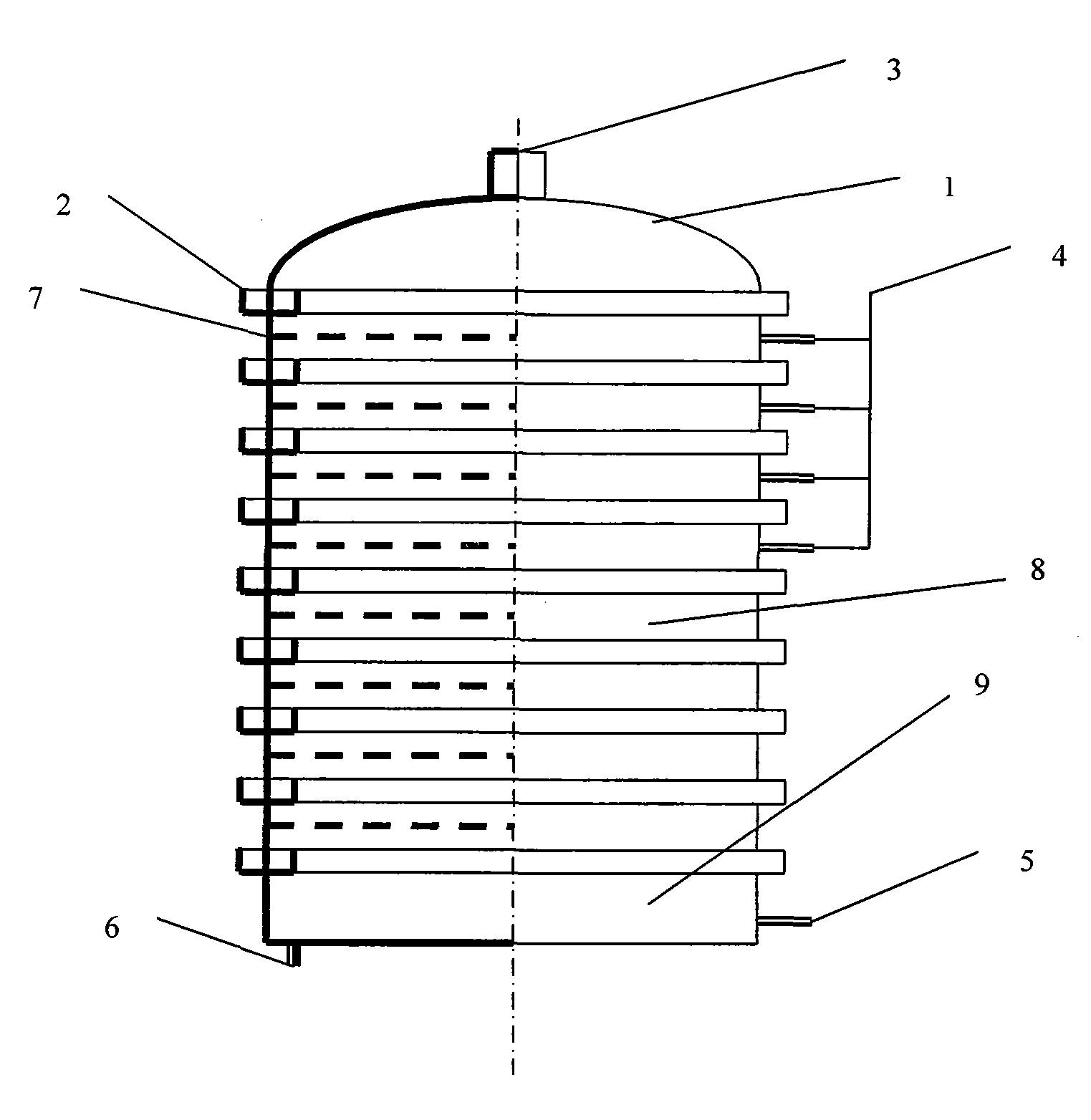

[0017] As shown in the figure, the cage-type multi-purpose solid anaerobic fermentation device of the present invention is composed of the following structure: a bottom tank body 9, an intermediate tank body 8 is provided above the bottom tank body 9, and a tank cover 1 is provided above the intermediate tank body 8 , the outer edge of the upper part of the bottom tank body 9 and the middle tank body 8 is an annular groove 2, and liquid is provided in the annular groove 2, the bottom of the middle tank body 8 is located in the annular groove 2, and the bottom of the middle tank body 8 is provided with There is a sieve plate 7, the bottom tank body 9 is provided with a steam inlet 5, the steam inlet 5 is arranged on the side wall of the bottom tank body 9, the bottom surface of the bottom tank body 9 is provided with a sewage outlet 6, and the top of the tank cover 1 is provided with The gas outlet 3, the tank cover 1 is arched, and the tank cover 1 is covered in the annular gro...

Embodiment 2

[0019] The sieve plate 7 in the embodiment 1 is replaced by grating bars, the intermediate tank body 8 has 5 layers, and the annular groove is provided with a flexible sealing material, and the others are the same as in the embodiment 1.

[0020] The bottom tank is made of carbon steel and other metals, and can also be made of reinforced concrete or other materials. It can be constructed on the ground, underground or semi-underground. It is mainly used to support the upper structure, collect residual liquid and seal; sieve plate or grate The bar is used to carry the material. In order to adapt to the distillation process, the intermediate tank body is provided with a return pipe according to the need;

[0021] Method of use of the present invention

[0022] First, inject liquid (such as water) into the sealed annular groove of the bottom tank body or put in flexible materials that can play a sealing role, and then install the intermediate tank bodies in sequence, one section a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com