Manufacturing method of aluminum alloy electrophoresis wood grain profile

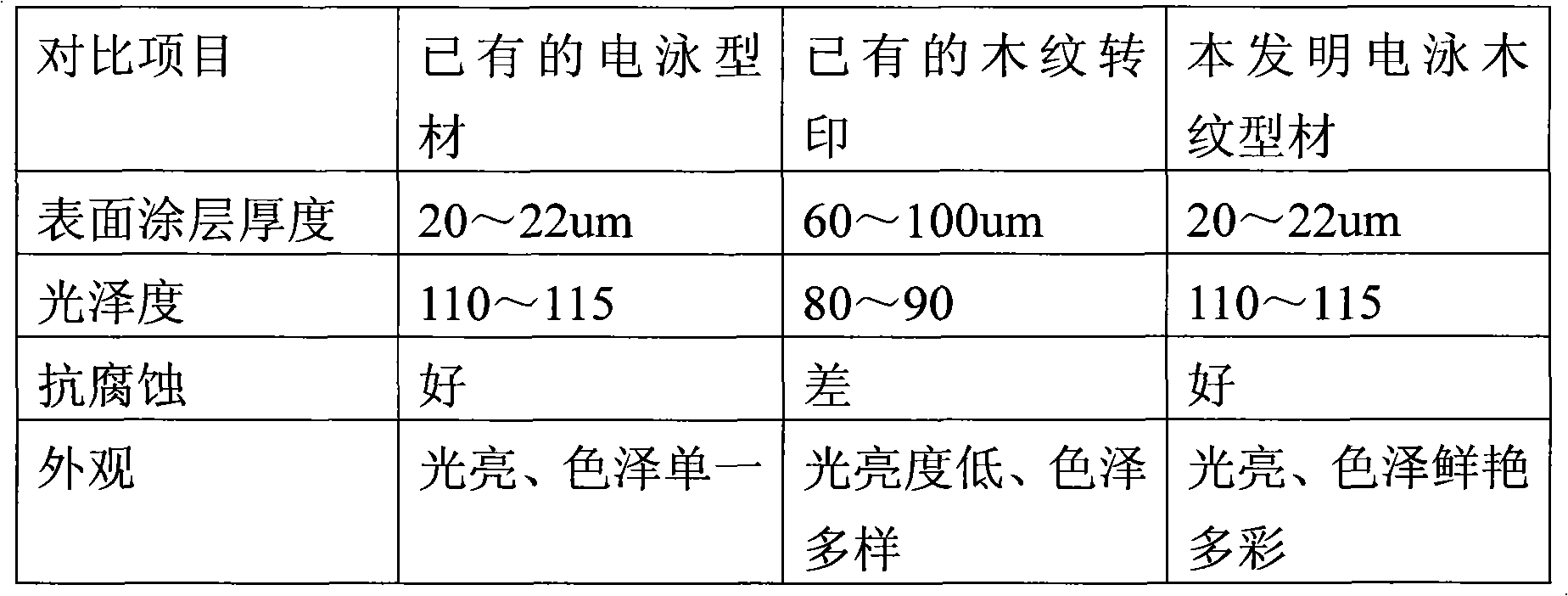

A production method and technology of aluminum alloy, applied in the direction of electrophoretic plating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of leaking the background color of the substrate, affecting the appearance quality, uneven thickness of the coating, etc., and achieve strong adhesion , avoid appearance defects, good coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Conventional aluminum alloy substrate degreasing-two washings-acid etching-two washings-alkali etching-two washings-neutralization-two washings-anodizing-two washings-pure water washing-electrolytic coloring-two washings- Pure water washing-hot water washing-electrophoresis-1 water washing-2 water washing-drip dry-electrophoretic paint curing, the curing temperature is 190°C, the time is 26 minutes, and then the wood grain is transferred, the transfer temperature is 185°C, and the transfer time is In 23.5 minutes, the aluminum alloy electrophoresis wood grain profile product was finally obtained. The surface coating thickness of the profile is 22um, the gloss is 110, it has good corrosion resistance, bright appearance and bright and colorful color.

Embodiment 2

[0016] Conventional aluminum alloy substrate degreasing-two washings-acid etching-two washings-alkali etching-two washings-neutralization-two washings-anodizing-two washings-pure water washing-electrolytic coloring-two washings- Pure water washing-hot water washing-electrophoresis-1 water washing-2 water washing-drip dry-electrophoretic paint curing, the curing temperature is 195°C, the time is 25 minutes, and then the wood grain is transferred, the transfer temperature is 187°C, and the transfer time is In 23.3 minutes, the aluminum alloy electrophoretic wood grain profile product was finally obtained. The thickness of the profile surface coating is 20um, the glossiness is 110, the corrosion resistance is good, the appearance is bright, and the color is bright and colorful.

Embodiment 3

[0018] Conventional aluminum alloy substrate degreasing-two washings-acid etching-two washings-alkali etching-two washings-neutralization-two washings-anodizing-two washings-pure water washing-electrolytic coloring-two washings- Pure water washing-hot water washing-electrophoresis-1 water washing-2 water washing-drip dry-electrophoretic paint curing, the curing temperature is 200°C, the time is 24 minutes, and then the wood grain is transferred, the transfer temperature is 190°C, and the transfer time is In 23 minutes, the aluminum alloy electrophoresis wood grain profile product was finally obtained. The thickness of the profile surface coating is 21um, the gloss is 113, the corrosion resistance is good, the appearance is bright, and the color is bright and colorful.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com