Collector used for negative pole of lithium ion battery

A lithium-ion battery and current collector technology, applied in the direction of electrode carrier/collector, can solve the problems of battery cycle attenuation, affecting the performance of lithium-ion batteries, uneven coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

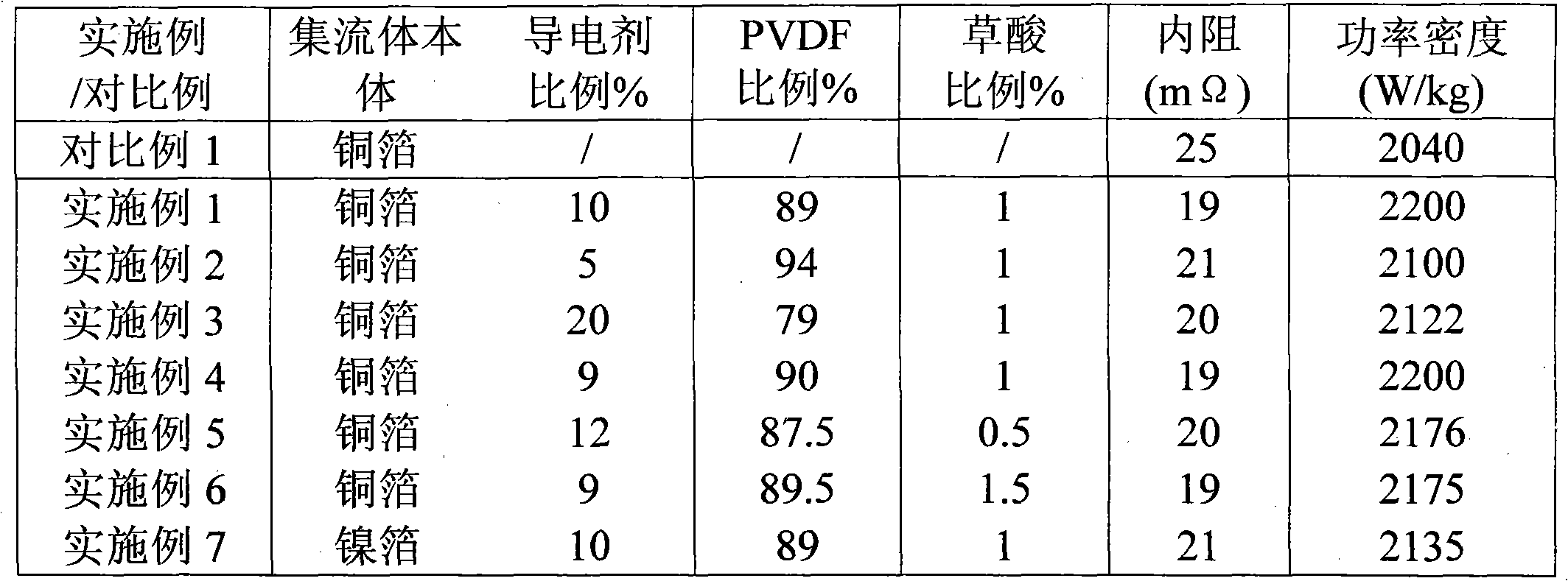

Examples

Embodiment 1

[0018] Positive electrode production:

[0019] Lithium iron phosphate (LiFePO4) is used as the negative electrode active material. A slurry containing the active material was prepared, and the solid content of the slurry contained 90% of the positive electrode active material, 5% of PVDF (polyvinylidene fluoride) as a binder, and 5% of conductive carbon as an electrical conduction aid. The slurry uses NMP as a solvent, and the weight of the solvent accounts for 30% of the total slurry weight. The slurry is evenly coated on both sides of the Al foil, and then calendered by a roller press to obtain a positive electrode membrane.

[0020] Negative electrode current collector treatment:

[0021] Copper foil is used as the negative electrode current collector body, and the treatment layer is: by weight percentage, composed of 10% conductive carbon with a D50 of 100um, 89% polyvinylidene fluoride and 1% oxalic acid. Mix the treatment layers, and stir with water as a solvent to fo...

Embodiment 2

[0027] The difference from Example 1 is that the treatment layer is: by weight percentage, composed of 5% conductive carbon with a D50 of 100um, 94% polyvinylidene fluoride and 1% oxalic acid. Other than that, the others are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] The difference from Example 1 is that the treatment layer is: by weight percentage, composed of 20% conductive carbon with a D50 of 100um, 79% polyvinylidene fluoride and 1% oxalic acid. The printing thickness is 4nm. Other than that, the others are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com