Preparation method of liposome medicine with outer layer modified by hydrophilic polymer

A technology of hydrophilic polymers and hydrophilic polymers, applied in the field of preparation of drugs for the treatment of tumor diseases, can solve problems such as difficult control of yield, difficulty in industrialization, phospholipid hydrolysis, etc., to achieve sustained release and targeting, The effect of improving economic benefits and high encapsulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 does not contain the preparation of the liposome of hydrophilic polymer

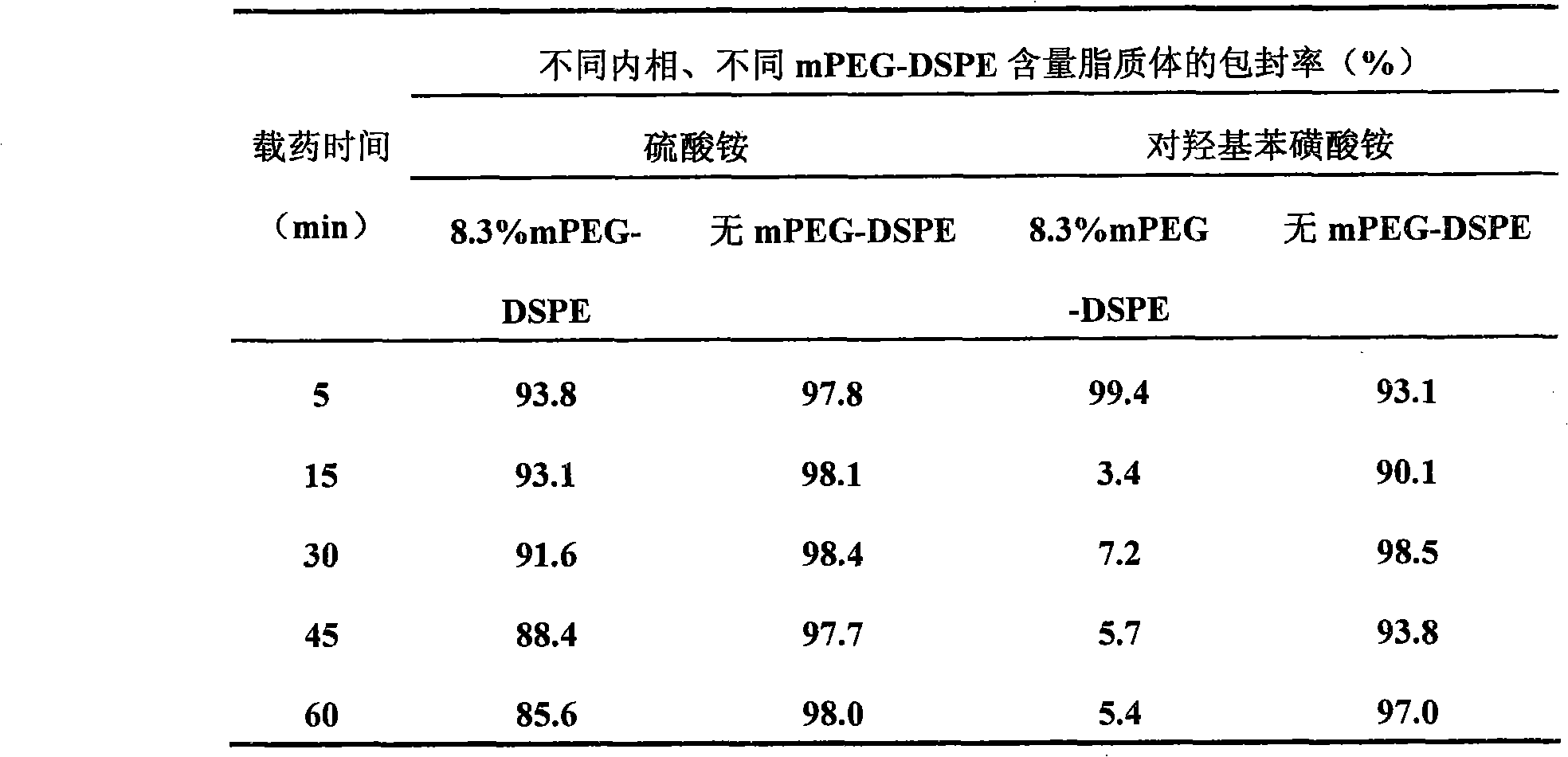

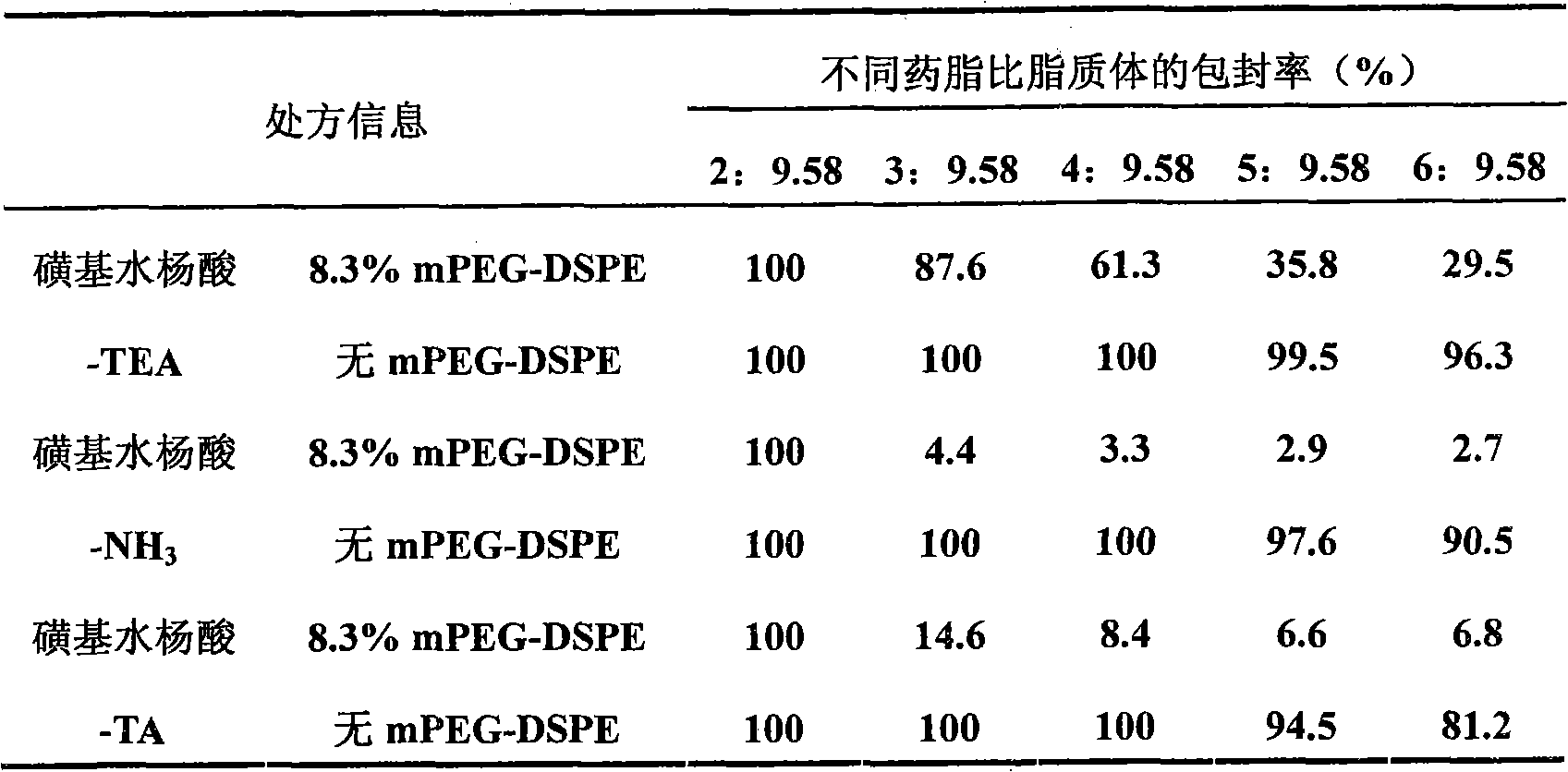

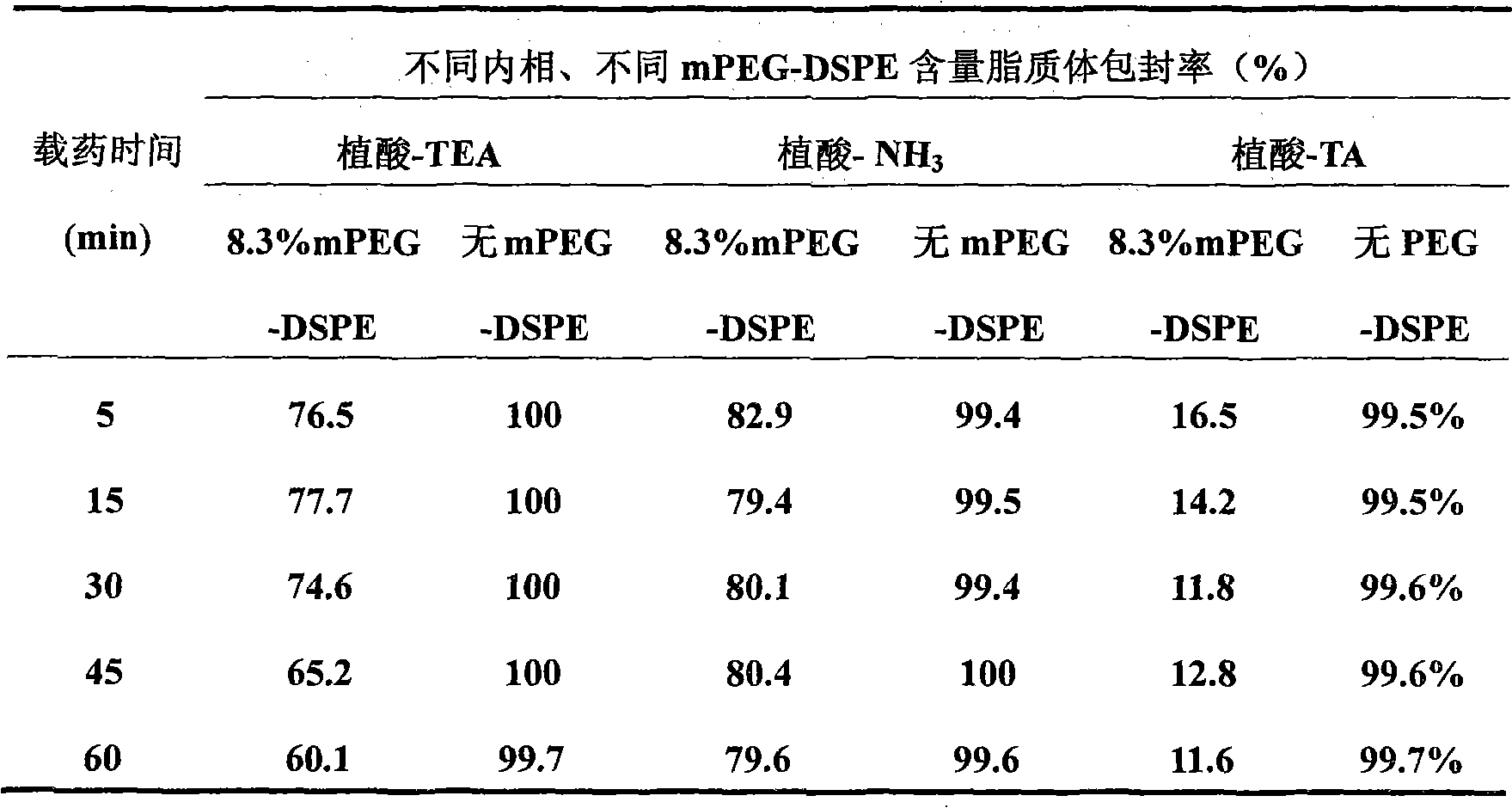

[0016] Mix phospholipids, such as hydrogenated soybean lecithin (or bispalmitate lecithin or bis myristate lecithin), with cholesterol at a weight ratio of 3:1, dissolve in 95% tert-butanol, and freeze-dry in a lyophilizer The organic solvent is removed to form a loose lipid phase mixture lyophilized powder, and the lyophilized powder is hydrated with a solution containing counter ions to form blank liposomes. The blank liposomes use high-pressure extrusion equipment or micro-fluidic equipment to reduce the particle size of liposomes, and then use column chromatography or dialysis means to remove counterions outside the liposomes with sucrose-histidine solution as the external phase. This creates an ion gradient inside and outside the lipid membrane. The aqueous drug solution is mixed with the liposome suspension, and incubated at 50-60° C. to obtain liposomes without hydrophilic pol...

Embodiment 2

[0017] The preparation of the liposome modified by embodiment 2 bilayer hydrophilic polymer

[0018] Mix phospholipids, such as hydrogenated soybean lecithin (or bispalmitate lecithin or bis myristate lecithin), cholesterol with a weight ratio of 3:1, and an appropriate amount of lipids derived from hydrophilic polymers, and dissolve them in In 95% tert-butanol, lyophilize in a lyophilizer to remove the organic solvent to form a loose lipid phase mixture lyophilized powder, and hydrate the lyophilized powder with a solution containing counter ions to form blank liposomes. The blank liposomes use high-pressure extrusion equipment or micro-fluidic equipment to reduce the particle size of liposomes, and then use column chromatography or dialysis means to remove counterions outside the liposomes with sucrose-histidine solution as the external phase. This creates an ion gradient inside and outside the lipid membrane. The drug aqueous solution is mixed with the liposome suspension,...

Embodiment 3

[0019] The preparation of the liposome modified by embodiment 3 outer layer hydrophilic polymer

[0020]Mix phospholipids, such as hydrogenated soybean lecithin (or bispalmitate lecithin or bis myristate lecithin), with cholesterol at a weight ratio of 3:1, dissolve in 95% tert-butanol, and freeze-dry in a lyophilizer The organic solvent is removed to form a loose lipid phase mixture lyophilized powder, and the lyophilized powder is hydrated with a solution containing counter ions to form blank liposomes. Blank liposomes use high-pressure extrusion equipment or micro-fluidic equipment to reduce the particle size of liposomes, and then use column chromatography or dialysis means to use sucrose histidine solution as the external phase to remove counterions outside the liposome, so that the liposomes An ion gradient is formed inside and outside the membrane. Mix the drug aqueous solution with the liposome suspension, and incubate at 50-60°C to obtain drug-containing liposomes, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com