Top silver-cladding gold nanorod array and preparation method and application thereof

A gold nanorod and silver-coated technology, which is applied to the gold nanorod array and its preparation field coated with silver on the top, can solve the problems of poor gold nanowire array, unstable SERS activity, and affecting SERS effect, and achieve enhanced enhancement Peak, excellent array, good array effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The concrete steps of preparation are:

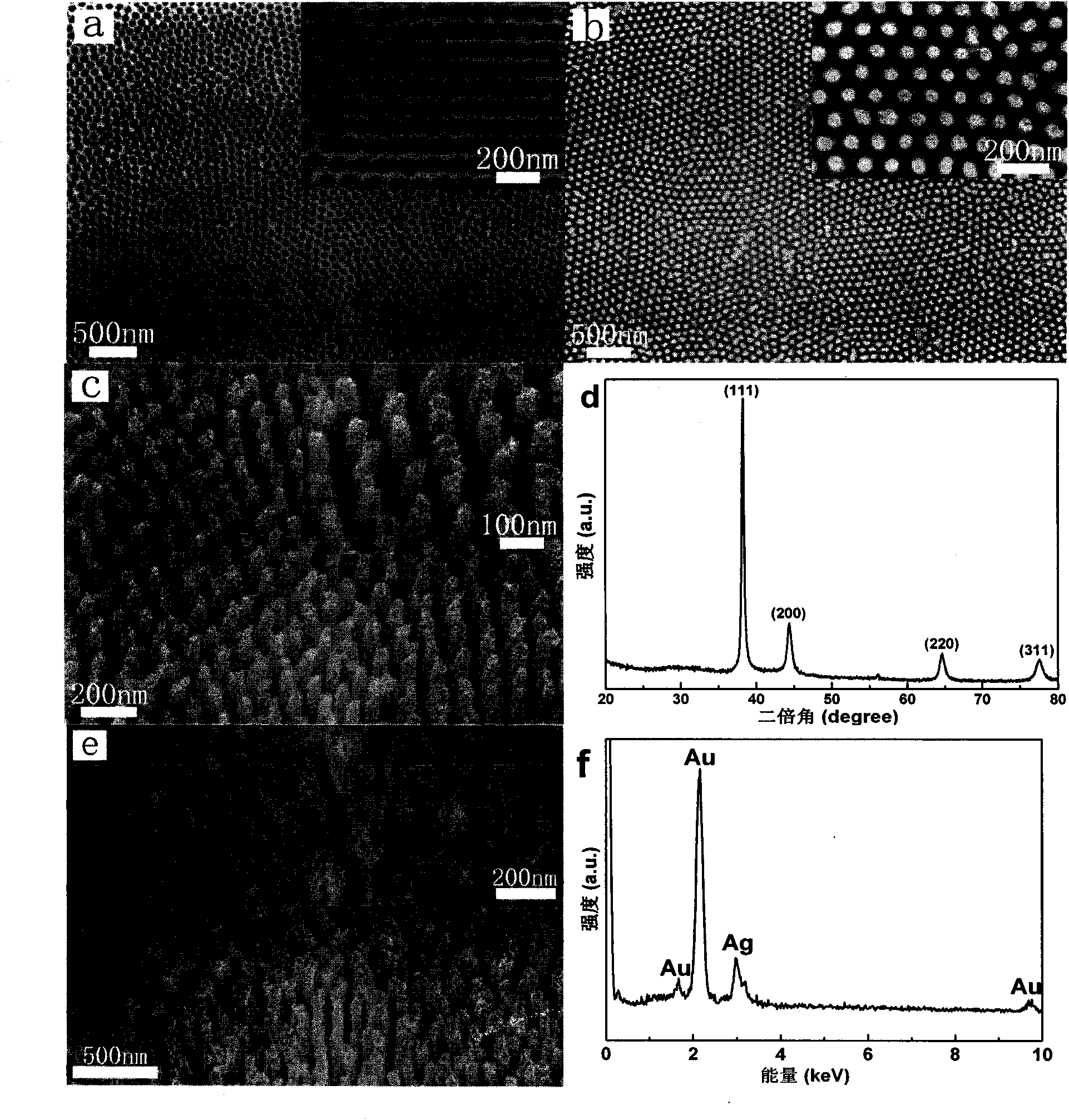

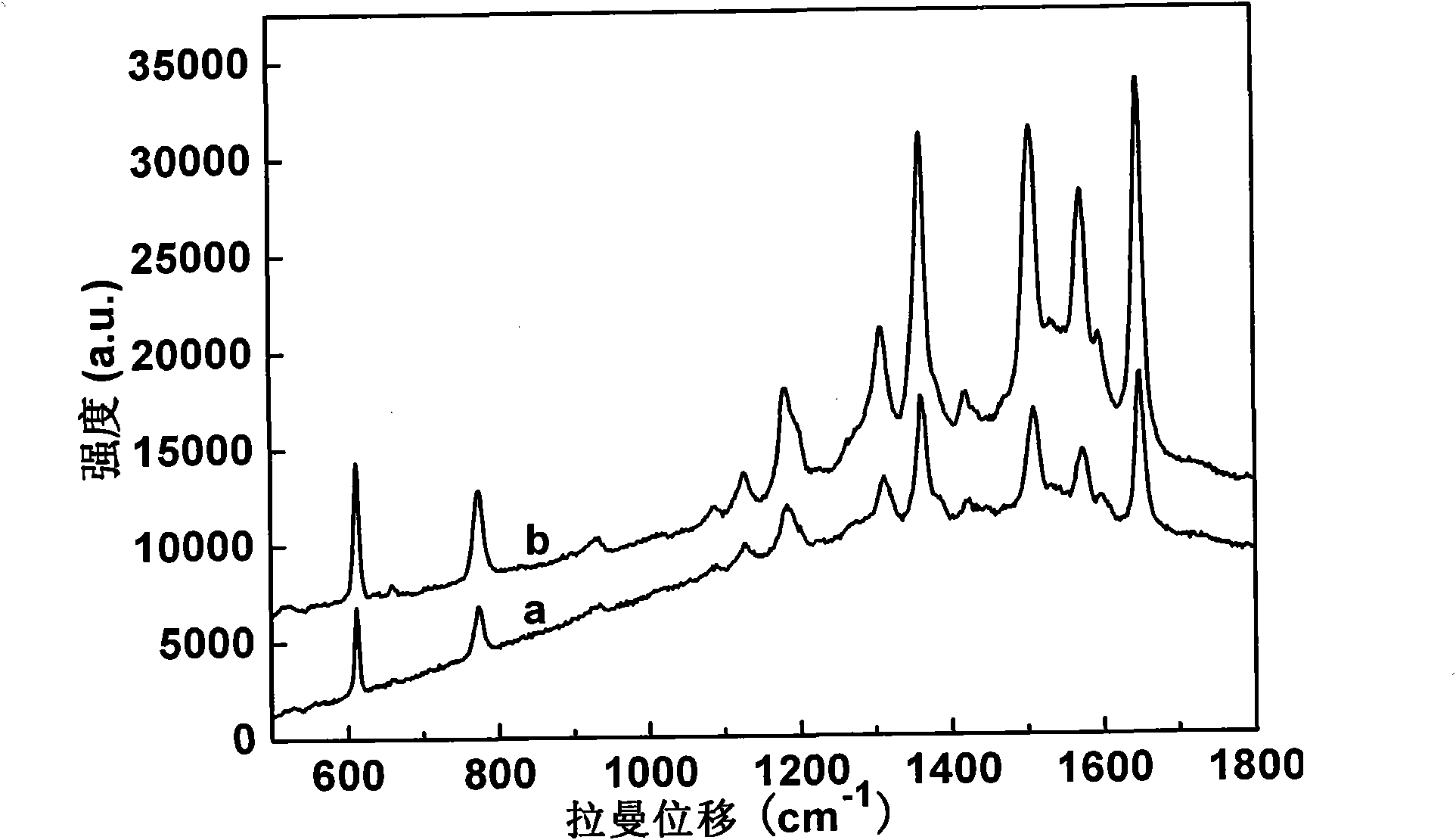

[0029] Step 1: Coating a liquid organic matter on the gold film on the side where the gold nanorod array is not grown, wherein the liquid organic matter is α-ethyl cyanoacrylate; organic substrate. Then place the aluminum oxide template with a gold film deposited on one side, gold nanorod arrays deposited in the holes, and organic matter coated on the gold film in an acid or alkaline solution to corrode the aluminum oxide template; figure 1 b and figure 1 as shown in c, and as figure 1 The gold nanorod array shown by the curve in d.

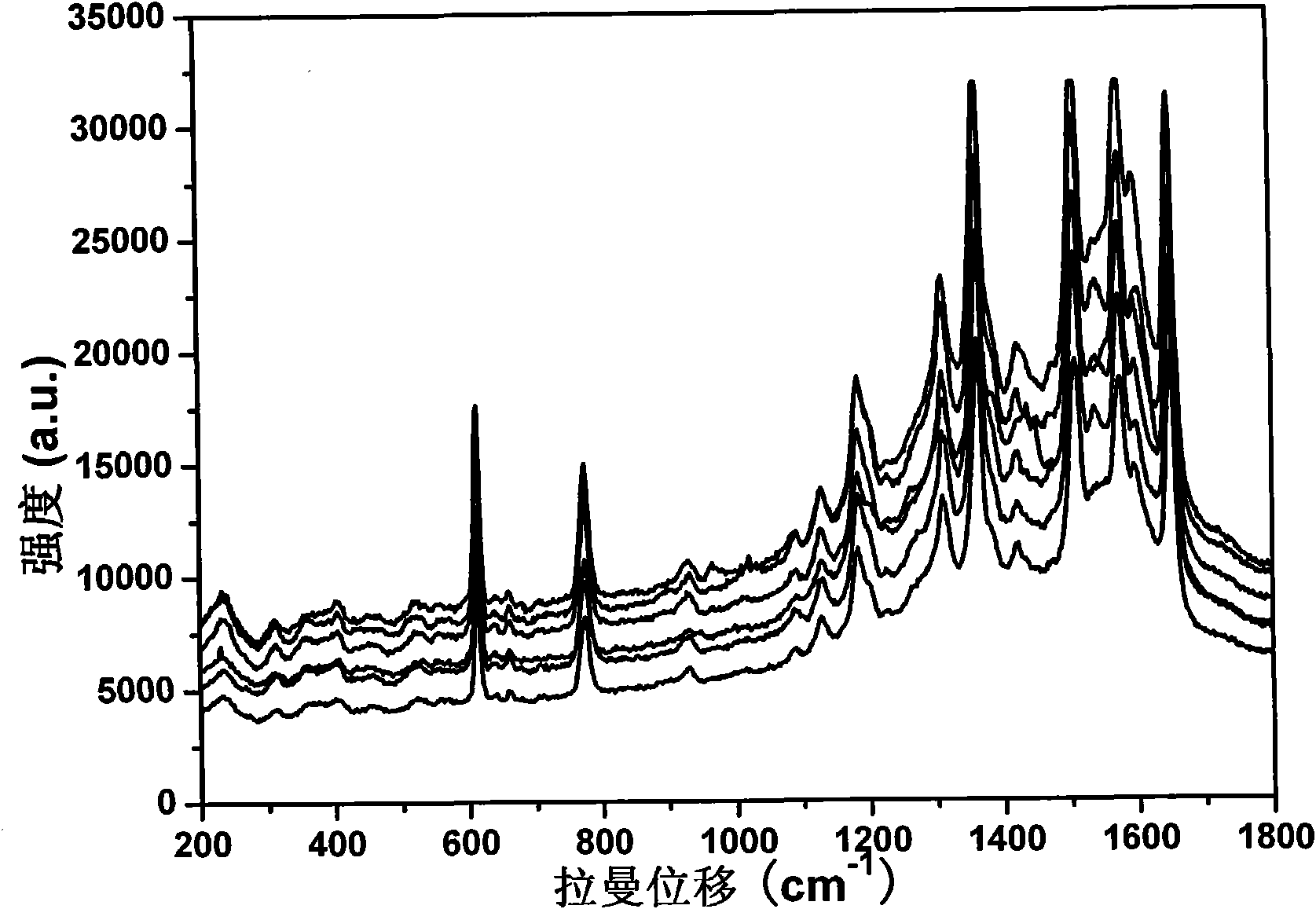

[0030] Step 2, using thin film evaporation technology to evaporate silver on the top of the gold nanorod array, wherein the thin film evaporation technology uses ion sputtering technology (or electron beam evaporation technology or vacuum evaporation technology), and its sputtering current is 3.5mA, The sputtering time is 0.5 min. The diameter of the obtained silver nanoparticles is 60nm, which...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1: Coating a liquid organic matter on the gold film on the side where the gold nanorod array is not grown, wherein the liquid organic matter is α-ethyl cyanoacrylate; organic substrate. Then place the aluminum oxide template with a gold film deposited on one side, gold nanorod arrays deposited in the holes, and organic matter coated on the gold film in an acid or alkaline solution to corrode the aluminum oxide template; figure 1 b and figure 1 as shown in c, and as figure 1 The gold nanorod array shown by the curve in d.

[0035] Step 2, using thin film evaporation technology to evaporate silver on the top of the gold nanorod array, wherein the thin film evaporation technology uses ion sputtering technology (or electron beam evaporation technology or vacuum evaporation technology), and its sputtering current is 3.25mA, The sputtering time is 1 min. The diameter of the obtained silver nanoparticles is 68nm, which ...

Embodiment 3

[0038] The concrete steps of preparation are:

[0039] Step 1: Coating a liquid organic matter on the gold film on the side where the gold nanorod array is not grown, wherein the liquid organic matter is α-ethyl cyanoacrylate; organic substrate. Then place the aluminum oxide template with a gold film deposited on one side, gold nanorod arrays deposited in the holes, and organic matter coated on the gold film in an acid or alkaline solution to corrode the aluminum oxide template; figure 1 b and figure 1 as shown in c, and as figure 1 The gold nanorod array shown by the curve in d.

[0040] Step 2, using thin film evaporation technology to evaporate silver on the top of the gold nanorod array, wherein the thin film evaporation technology adopts ion sputtering technology (or electron beam evaporation technology or vacuum evaporation technology), and its sputtering current is 3mA, sputtering The injection time is 3 minutes. Silver nanoparticles with a diameter of 75 nm, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com