Chiffon cake pre-blend flour requiring no egg separation, chiffon cake adopting pre-blend flour, and preparation method of chiffon cake

A chiffon cake and pre-mixed powder technology, which is applied in dough processing, baking, baked food, etc. It can solve the problems that the elastic texture of protein cannot be expressed, the quality of chiffon cake cannot be satisfied, and the production process of egg separation is complicated, etc. , to achieve a more elastic taste, water retention performance that melts in the mouth, and avoid unstable bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

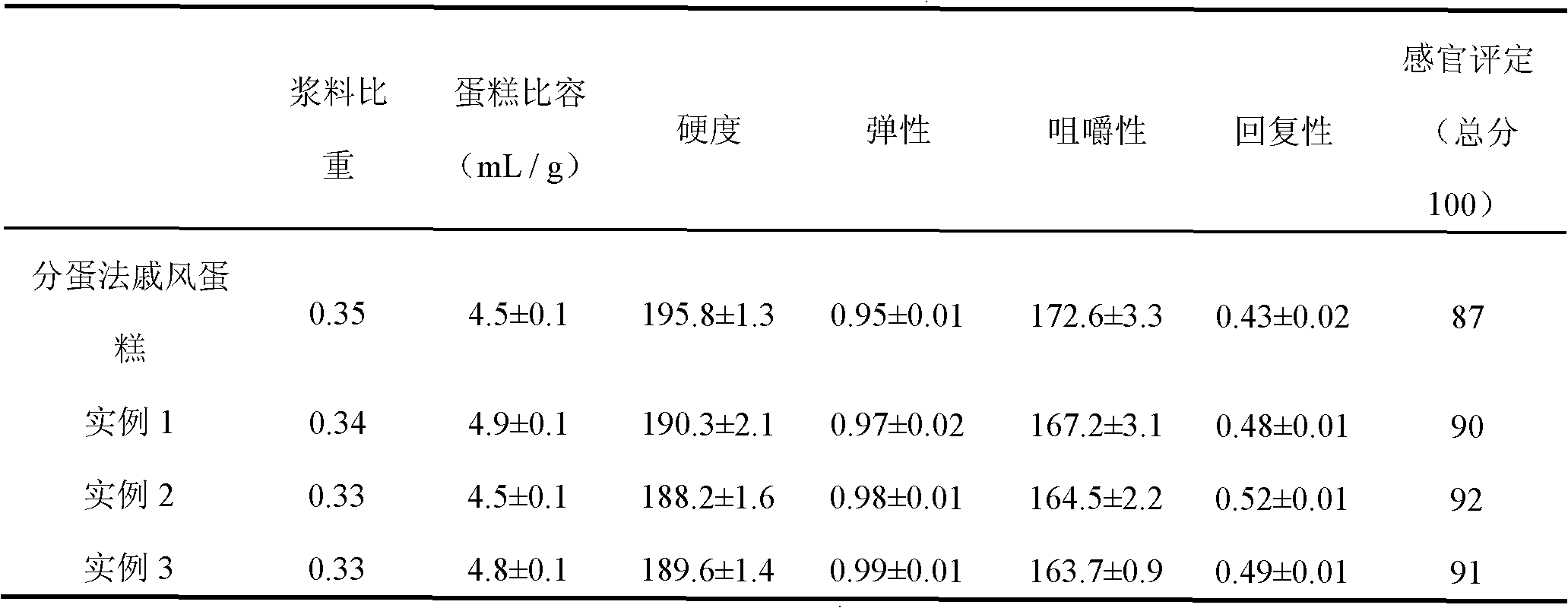

Examples

Embodiment 1

[0042] (1) 450g of sucrose powder, 450g of low-gluten flour, 60g of egg protein powder (protein content 78-80%, produced by Japan Sun Chemical Co., Ltd.), 30g of pregelatinized hydroxypropyl distarch phosphate starch, carboxymethyl cellulose Mix 4g of sodium, 2g of salt, 2g of acidity regulator citric acid and 2g of milk powder essence, and stir evenly in a mixing mixer to obtain 1kg of chiffon cake premix;

[0043] (2) Put the hurricane cake premix powder obtained in step (1) into the mixing tank, then add 1.4kg of whole egg liquid, 40g of instant cake oil, and 200g of water, and stir at 10rpm for 3 minutes. During the mixing process, pay attention to scraping the side of the tank and Bottom of the cylinder to prevent the material from sinking to the bottom;

[0044] (3) Send the cake slurry obtained in step (2) for 3 minutes at a speed of 40 rpm, and then send it for 1.5 minutes at a speed of 70 rpm;

[0045] (4) Adjust the mixer to a slow speed (10rpm), and add soybean sal...

Embodiment 2

[0048] (1) 500g of sucrose powder, 400g of low-gluten flour, 70g of egg protein powder (protein content 78-80%), 20g of pregelatinized acetylated distarch phosphate starch, 4g of guar gum, 2g of salt, and acidity regulator Mix 2 g of citric acid and 2 g of egg powder essence, and stir evenly in a mixing mixer to obtain 1 kg of chiffon cake premix;

[0049] (2) Put the hurricane cake premix powder obtained in step (1) into the mixing tank, then add 1.5kg of whole egg liquid, 50g of instant cake oil, and 200g of water, and stir for 3 minutes at a speed of 15rpm. During the mixing process, pay attention to scraping the cylinder The sides and the bottom of the cylinder prevent the material from sinking to the bottom;

[0050] (3) Send the cake slurry obtained in step (2) at a speed of 45 rpm for 3 minutes, and then send it at a speed of 75 rpm for 1.5 minutes;

[0051] (4) The stirrer is transferred to 15rpm, and the cake slurry obtained in step (3) is added with corn salad oil a...

Embodiment 3

[0054] (1) 440g of sucrose powder, 440g of low-gluten flour, soybean protein powder (isolated soybean protein, protein content 89-92%, produced by Shandong Wandefu Industrial Company) 80g, pregelatinized hydroxypropyl distarch phosphate starch 16g , 10g of pregelatinized acetylated distarch phosphate starch, 4g of sodium carboxymethylcellulose, 4g of sodium alginate, 2g of table salt, 2g of acidity regulator citric acid and 2g of custard powder flavor, and stir evenly in a mixing mixer. Obtain chiffon cake premix 1kg;

[0055] (2) Put the hurricane cake premix powder obtained in step (1) into the mixing tank, then add 1.4kg of whole egg liquid, 40g of instant cake oil, and 200g of water, and stir for 3 minutes at a speed of 20rpm. During the mixing process, pay attention to scraping the cylinder The sides and the bottom of the cylinder prevent the material from sinking to the bottom;

[0056] (3) Send the cake slurry obtained in step (2) at a speed of 50 rpm for 3 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com