Method for treating high concentration wastewater of oil refinery

A high-concentration, oil refinery technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem that small molecular organic matter is difficult to completely remove, the effluent effect is difficult to meet the standard discharge, and the amount of oxidant is large, etc. problem, to achieve significant treatment effect, efficient and stable method, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

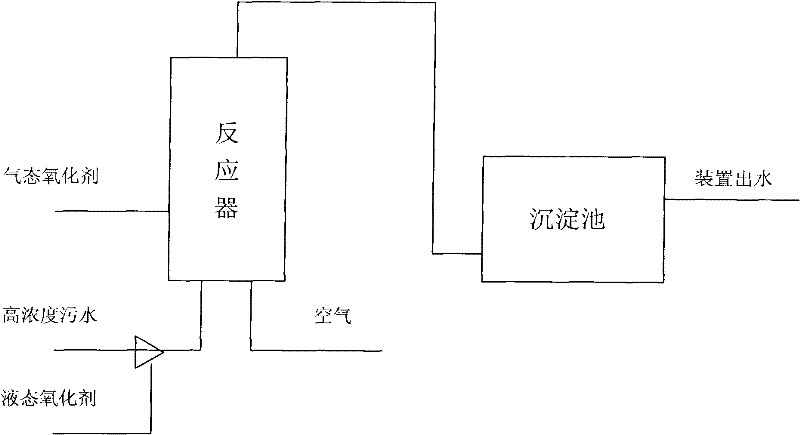

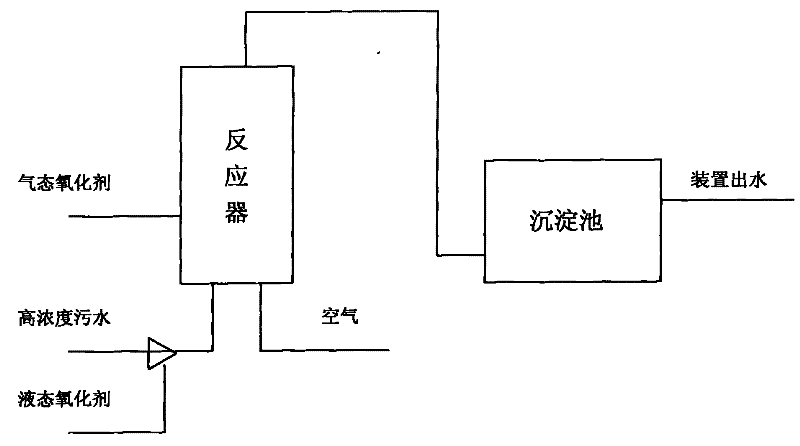

Method used

Image

Examples

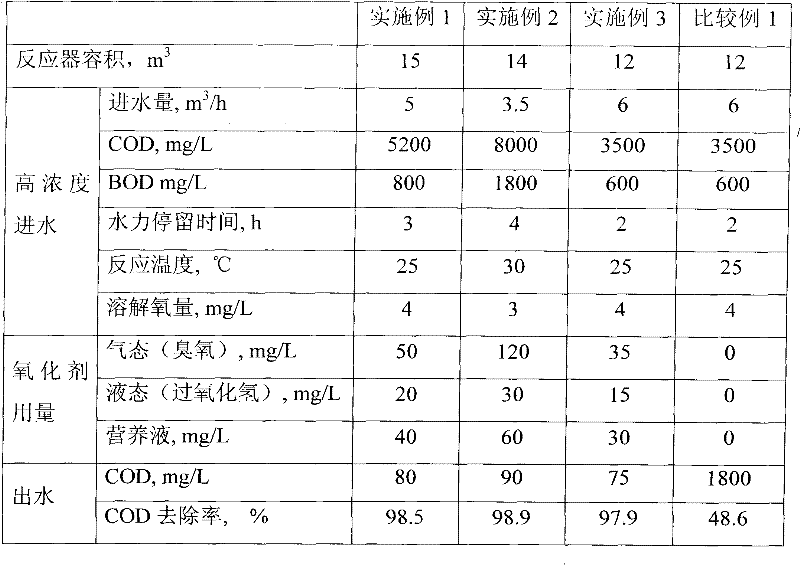

Embodiment 1

[0024] The high-concentration sewage discharged from the refinery, after degreasing treatment, the COD is 5200mg / L, and the BOD is 800mg / L, which belongs to the high-concentration sewage that is difficult to treat biologically. Under the following conditions, the reactor volume is 15m 3 , water intake 5m 3 / h, temperature 25°C, hydraulic retention time 3h, dissolved oxygen 4mg / L. Oxidants consist of a combination of gaseous and liquid forms. Ozone is used as a gaseous oxidant, the addition amount is 50 mg / L; hydrogen peroxide is used as a liquid oxidant, the addition amount is 20 mg / L, and the liquid oxidant is added to the reactor with nutrient solution 40 mg / L. After being treated by the process of the present invention, the COD in the treated effluent is 80 mg / L, the BOD is 5 mg / L, and the effluent reaches the discharge standard and is directly discharged.

Embodiment 2~3

[0026] Different process conditions were used to treat high-concentration wastewater from refineries with different concentrations. The conditions and treatment results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com