Production process for synthetizing EDDHA (Ethylenediamine-N,N'-bis(2-hydroxyphenylacetic acid) ferric-sodium complex) Ferrochel with one-step method

A production process, chelated iron technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of unfavorable environmental protection, high production cost, long process, etc., and achieve low production cost and no pollution Effect of energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

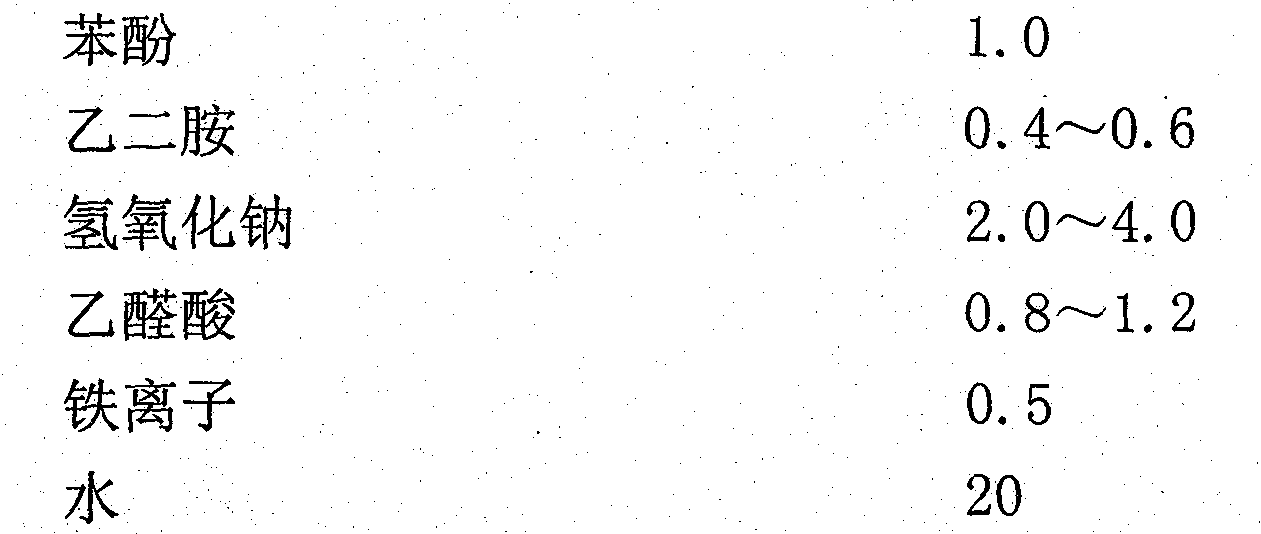

[0016] 1) Raw material ratio (molar ratio)

[0017] Phenol 1.0

[0018] Ethylenediamine 0.4

[0020] Glyoxylic acid 0.8

[0021] Iron ion (ferrous sulfate) 0.5

[0022] water 20

[0023] 2) Dissolve phenol with 10 moles of water, add ethylenediamine and sodium hydroxide solution dropwise to the phenol solution at a temperature of 100°C, mix well, then add glyoxylic acid dropwise, and react at this temperature for 2 hours, Get EDDHA aqueous solution, wherein the weight percent concentration of sodium hydroxide aqueous solution is 40%;

[0024] 3) Dissolve the iron salt in the remaining 10 moles of water, and when the temperature of the EDDHA aqueous solution in step 2) is lowered to 40°C, add the iron salt aqueous solution, adjust the pH to 7.0, stir and react for 15 minutes, and obtain the EDDHA chelated iron solution, which is dried Obtain 233g of EDDHA chelated iron of the present invention, yield 91%.

Embodiment 2

[0026] 1) Raw material ratio (molar ratio)

[0027] Phenol 1.0

[0028] Ethylenediamine 0.5

[0029] Sodium hydroxide 4.0

[0030] Glyoxylic acid 1.0

[0031] Iron ion (ferric chloride) 0.5

[0032] water 20

[0033] 2) Dissolve phenol with 10 moles of water, add ethylenediamine and sodium hydroxide solution dropwise to the phenol solution at 50°C, mix well, then add glyoxylic acid dropwise, and react at this temperature for 3 hours, Get EDDHA aqueous solution, wherein the weight percent concentration of sodium hydroxide aqueous solution is 40%;

[0034] 3) Dissolve the iron salt in the remaining 10 moles of water, and when the temperature of the EDDHA aqueous solution in step 2) is lowered to 40°C, add the iron salt aqueous solution, adjust the pH to 7.5, stir and react for 30 minutes to obtain the EDDHA chelated iron solution, and after drying Obtain 240.5 g of EDDHA chelated iron of the present invention, yield 94%.

Embodiment 3

[0036] 1) Raw material ratio (molar ratio)

[0037] Phenol 1.0

[0038] Ethylenediamine 0.6

[0040] Glyoxylic acid 1.2

[0041] Iron ion (ferrous ammonium sulfate) 0.5

[0042] water 20

[0043] 2) Dissolve phenol with 10 moles of water, add ethylenediamine and sodium hydroxide solution dropwise to the phenol solution at 70°C, mix well, then add glyoxylic acid dropwise, and react at this temperature for 2.5 hours , to get EDDHA aqueous solution, wherein the weight percent concentration of sodium hydroxide aqueous solution is 40%;

[0044] 3) Dissolve the salt in the remaining 10 moles of water, and add the iron salt solution when the temperature of the EDDHA aqueous solution in step 2) is lowered to 40° C., and adjust the pH to 6.5, and stir and react for 20 minutes to obtain the EDDHA chelated iron solution, which is obtained after drying. The EDDHA chelated iron of the present invention is 248g, and the yield is 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com