Water-based alkali swelling rheological agent and production method thereof

A technology of alkali swelling and rheological agent, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problems of unsatisfactory use effect and achieve the effect of low cost, simple production process and operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Emulsification: Add 63 grams of methacrylic acid, 59 grams of ethyl acrylate, 20 grams of allyl polyoxyalkylene epoxy ether, 15 grams of hydroxyethyl methacrylate, and diphthalate into a stainless steel kettle. 0.35 grams of allyl ester, 2.2 grams of sodium dodecylbenzenesulfonate, 340 grams of deionized water, stirred and emulsified for 20 minutes to make an emulsion;

[0020] (2) Initiate polymerization reaction: get 20% of the total amount of the emulsion, that is, 100 grams are added to the reactor, the temperature is raised to 75-80 ° C, the mixed solution of 0.069 grams of initiator ammonium persulfate and 1 gram of water is added, and the reaction is initiated. Add 399 grams of the remaining emulsion dropwise at a temperature of 85-90°C, and at the same time add dropwise a mixture of 0.231 grams of ammonium persulfate and 20 grams of deionized water. hours, then cool down to 30-40°C, filter and discharge;

Embodiment 2

[0022] The weight ratio of raw materials is: 64 grams of methacrylic acid, 60 grams of ethyl acrylate, 20.5 grams of allyl polyoxyalkylene epoxy ether, 15.5 grams of hydroxyethyl methacrylate, 0.38 grams of diallyl phthalate Gram, sodium dodecylbenzenesulfonate are 2.25 grams, 345 grams of deionized water; Ammonium persulfate 0.33 grams; Production process is with embodiment 1.

Embodiment 3

[0024] The weight ratio of raw materials is: 65 grams of methacrylic acid, 61 grams of ethyl acrylate, 21 grams of allyl polyoxyalkylene epoxy ether, 16 grams of hydroxyethyl methacrylate, 0.4 grams of diallyl phthalate Gram, sodium dodecylbenzenesulfonate are 2.3 grams, 350 grams of deionized water; Ammonium persulfate 0.35 grams; Production process is with embodiment 1.

[0025] The using method of water-based alkali-swellable rheology agent of the present invention:

[0026] Take 0.5-2% of this product and add it to the pigment printing paste, and adjust the pH value to 7.5-8, stir evenly, and then it can be used for printing.

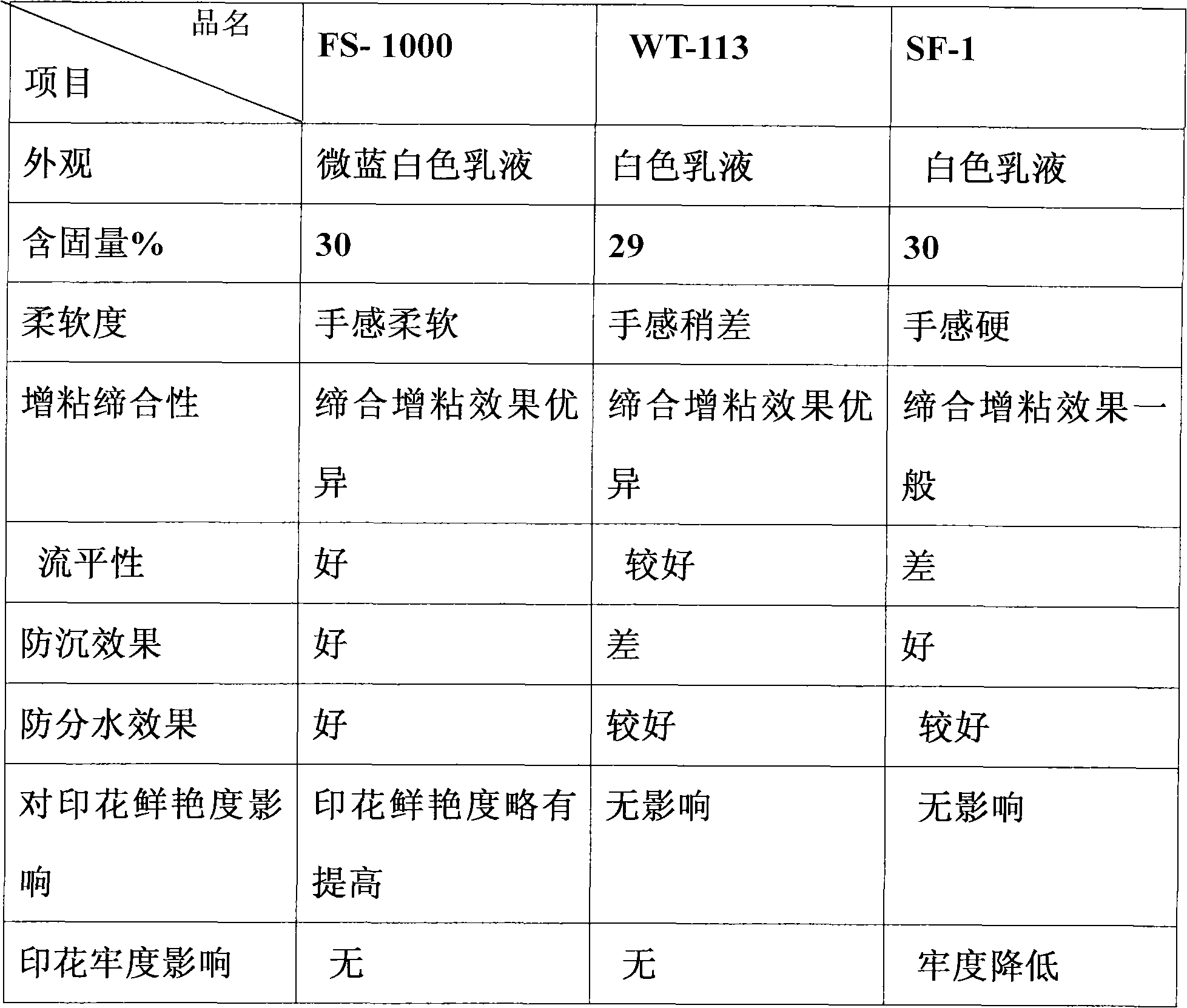

[0027] The comparison between this product (hereinafter referred to as FS-1000) and Deqian’s WT-113 product and domestic SF-1 product in textile printing paste:

[0028]

[0029] Through the above comparison, it can be known that FS-1000 product has excellent effects of association, thickening, leveling, anti-settling, and anti-water separation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com