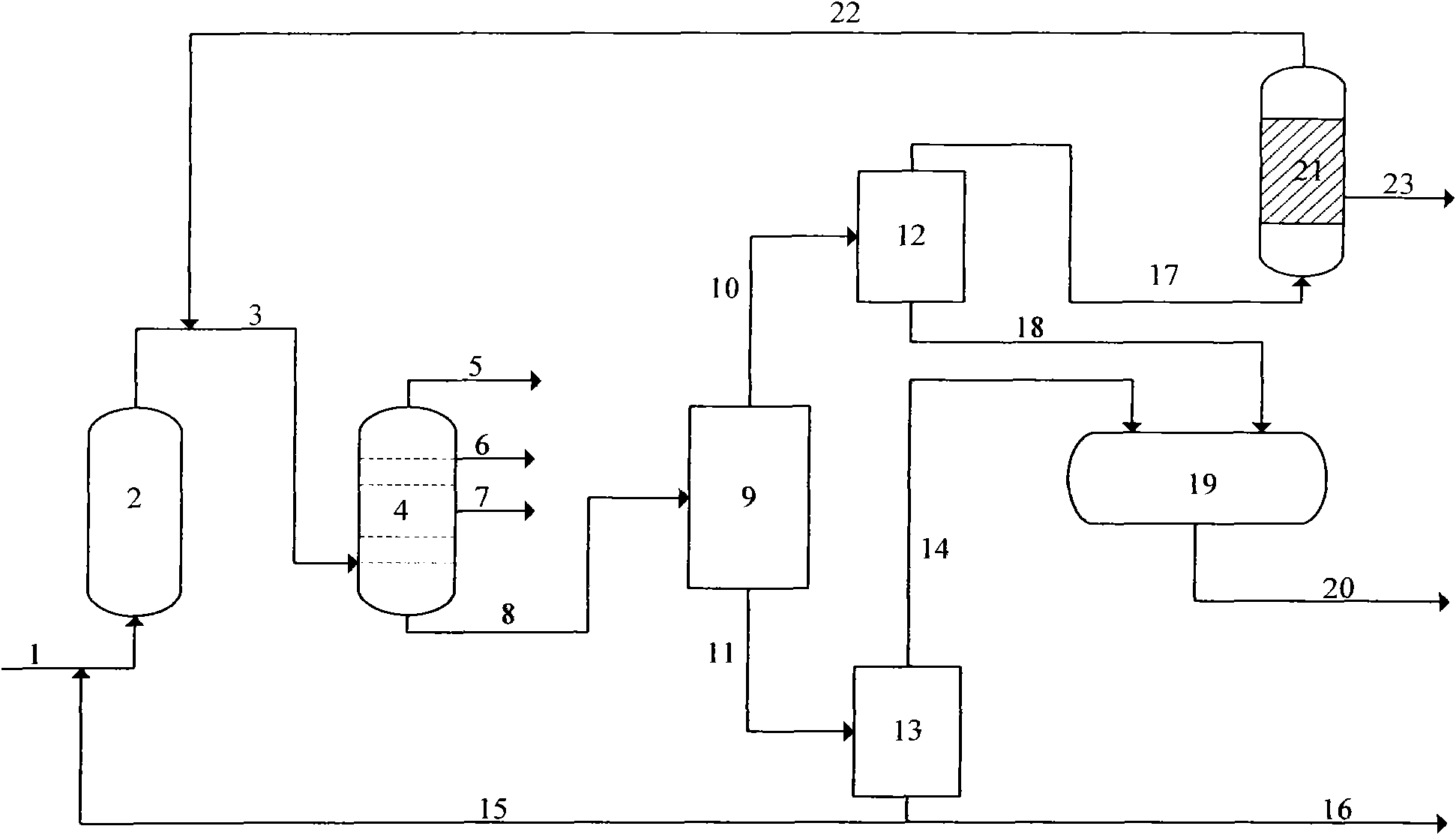

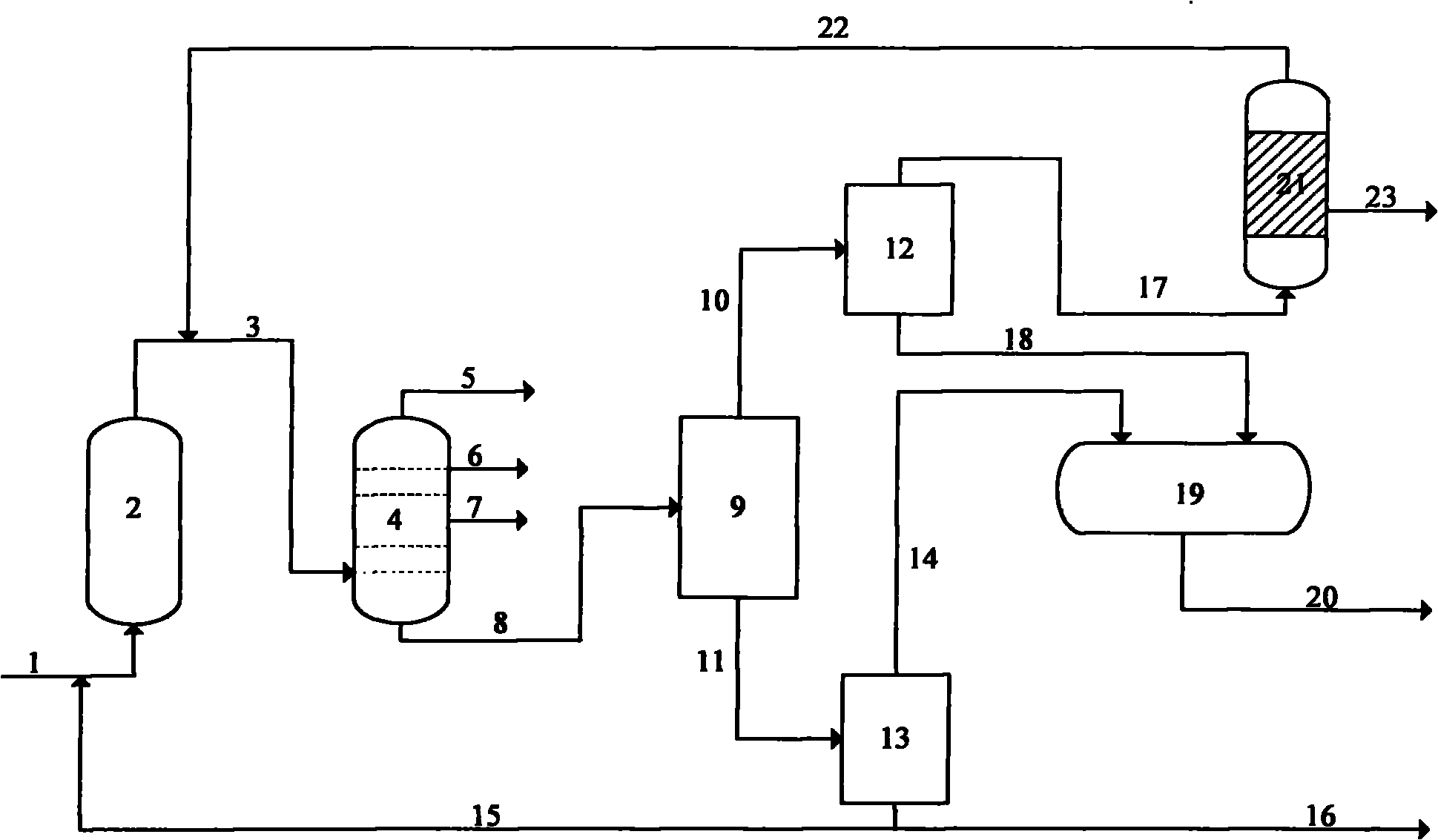

Method for producing needle coke by combined process

A combined process and needle coke technology, which is applied in the petroleum industry, only multi-stage series refining and cracking process treatment, cracking, etc., can solve the problems of increasing regenerator load, large amount of green coke, and low light oil yield , to achieve the effect of improving product quality, saving energy consumption and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]This embodiment adopts the combined process method of catalytic cracking, aromatics extraction and delayed coking provided by the present invention, and the liquid phase products of catalytic cracking and delayed coking enter the fractionation tower together to separate gas, gasoline and diesel oil, and the heavy oil passes through the aromatics extraction device, and the solvent is recovered The raffinated oil is directly sent to the catalytic cracking unit for refining, and the extracted oil after solvent recovery is sent to delayed coking to prepare needle coke. Table 1, Table 2, Table 3 and Table 4 respectively show the properties of raw material oil, process conditions and properties of the main product needle coke.

[0054] Table 1 Raw Oil Properties

[0055] name

Raw oil

Density (20℃), kg / m 3

927.8

Viscosity (80℃), mm 2 / s

77.49

Viscosity (100℃), mm 2 / s

37.26

S, mass%

0.36

N, μg / g

221...

Embodiment 2

[0062] Same as Example 1, during the coking reaction process after the delayed coking unit stops feeding, a small amount of nitrogen is introduced at the bottom of the coking unit, so that the exhaust volume of the coking reaction process reaches 0.05h-1 until the coking reaction ends, and the product quality is shown in Table 4.

Embodiment 3

[0064] Same as in Example 1, during the coking reaction process after the delayed coking unit stopped feeding, a small amount of C1-C4 mixed hydrocarbons produced during the coking process were introduced at the bottom of the coking unit, so that the exhaust volume of the coking reaction process reached 0.6h-1, Until the coking reaction ends, the product quality is shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com