Method for more producing light oil by using hydrocarbon oil

A technology for light oil and hydrocarbon oil, applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problems of reducing the yield of raw material light oil, etc., to achieve the best selectivity, increase the yield, reduce the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

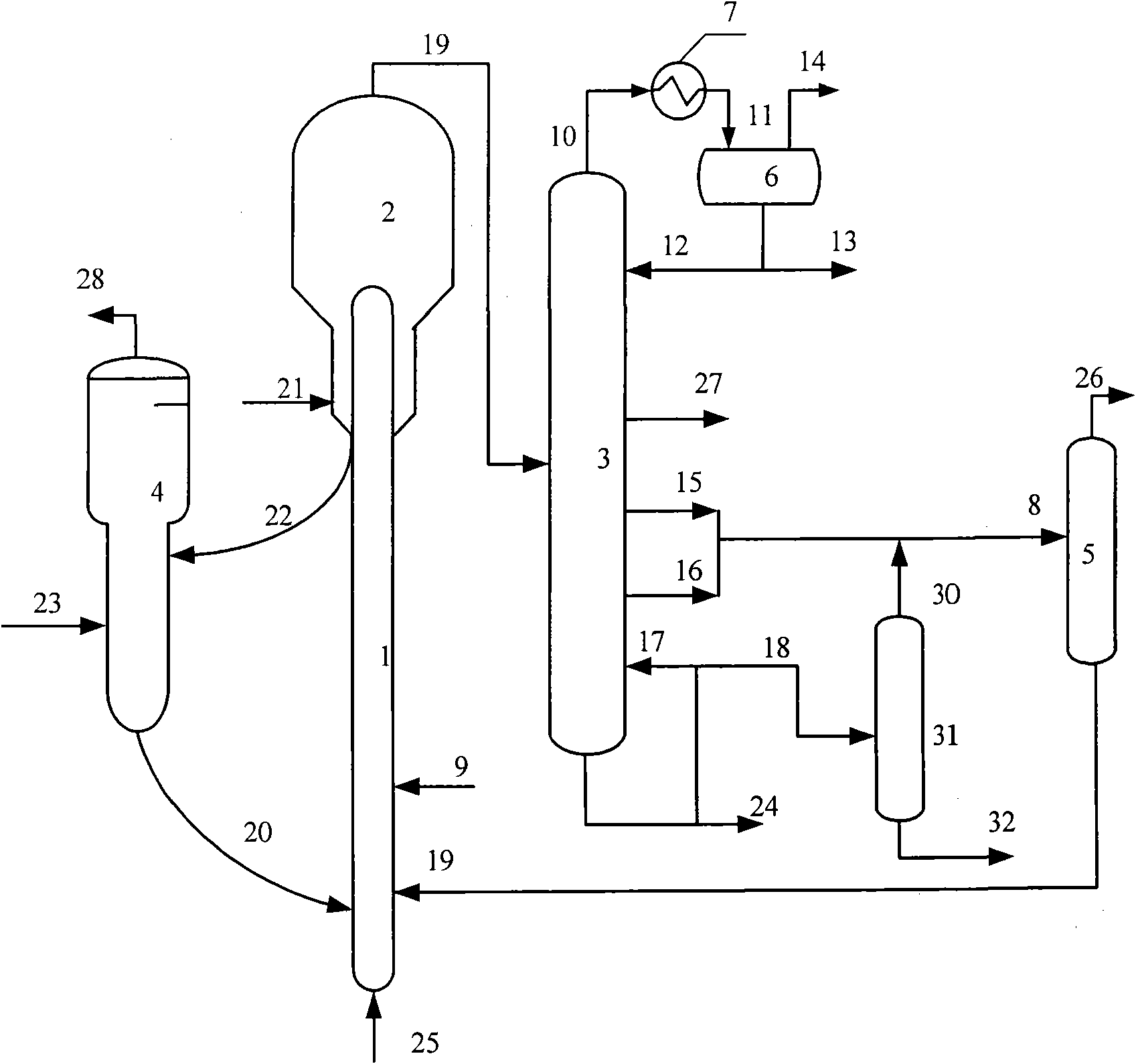

[0042] According to a preferred embodiment of the present invention, the method further includes repeating steps (2)-(5) for the catalytic cracking product obtained in step (5). The catalytic heavy oil after the separation of light components is hydro-upgraded and re-refined or sent to another catalytic cracking unit for catalytic cracking, thereby further increasing the yield of light oil.

[0043] In the present invention, the hydrocarbon oil can be selected from crude oil, atmospheric residual oil, vacuum residual oil, atmospheric gas oil, vacuum gas oil, straight run gas oil, propane light / heavy deoiling, coking gas oil and coal One or more of the liquefied products.

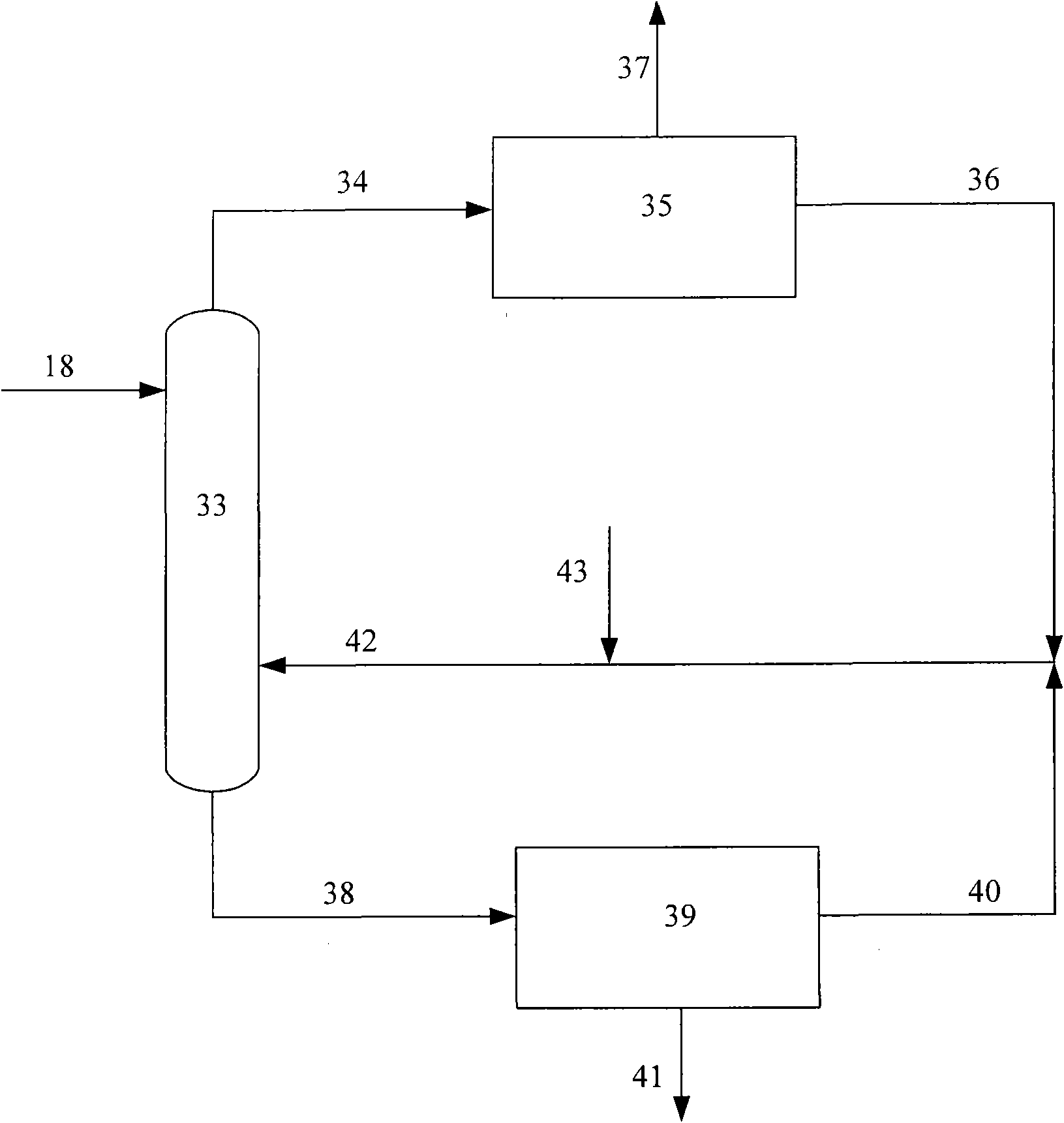

[0044] Preferably, the method provided by the present invention further includes separating the catalyst from the above-mentioned hydro-upgraded catalytic cracking product, the catalyst is sent to a regenerator for regeneration, and the oil and gas produced by the reaction enters the fractionation part of ca...

Embodiment 1

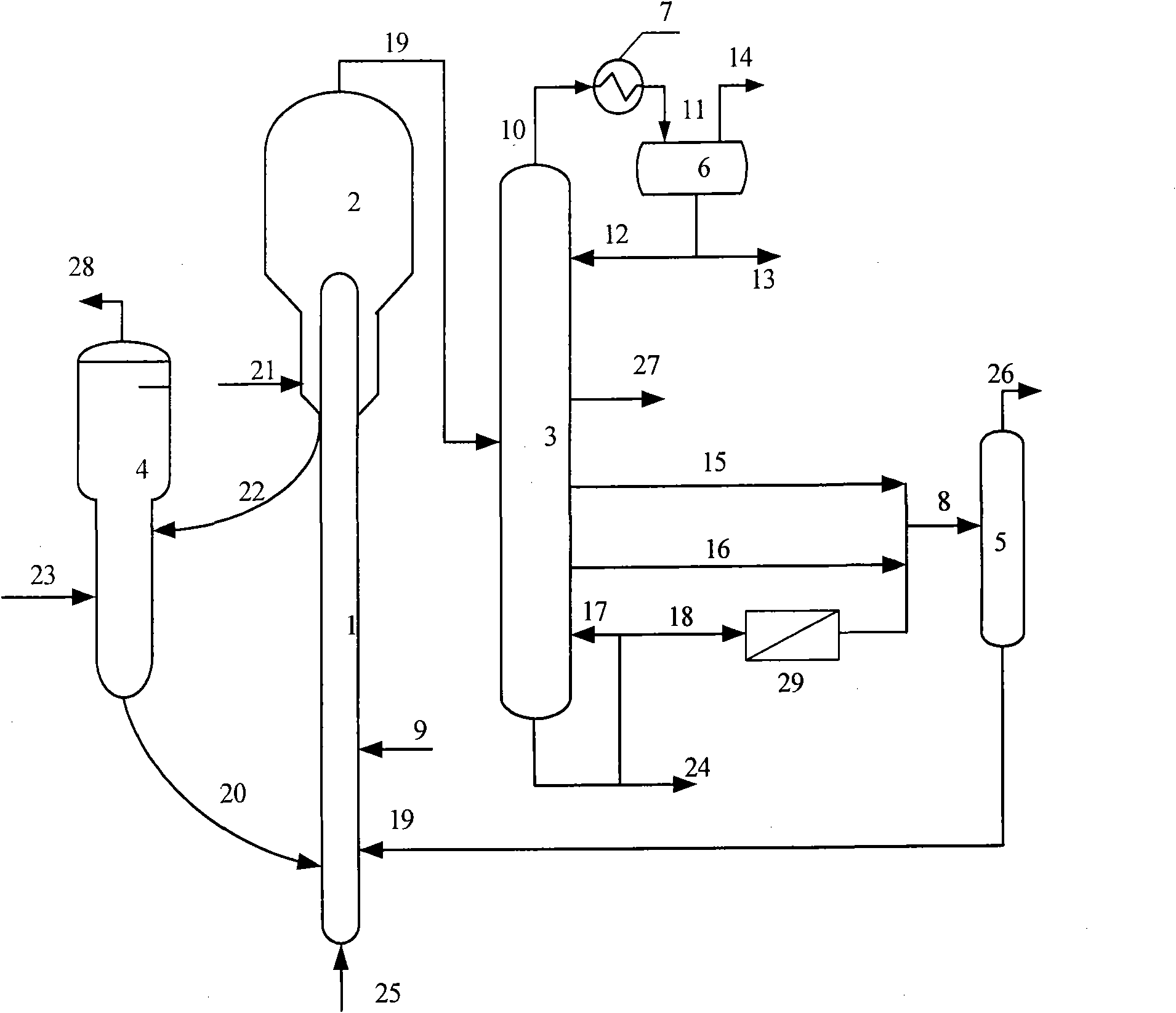

[0061] according to figure 1 The process shown is to produce light hydrocarbon oil from hydrocarbon oil, and the catalytic cracking reactor is a medium-sized riser catalytic cracking unit.

[0062] The properties of the raw material hydrocarbon oil used in the medium-sized catalytic cracking unit are shown in Table 1. The reaction conditions and product distribution of catalytic cracking are shown in Table 2.

[0063] The catalytic heavy oil in the catalytic cracking products shown in Table 2 is first removed most of the colloids and asphaltenes by solvent extraction. The extraction operation temperature is 190 ° C and the pressure is 5 MPa. The solvent and catalytic heavy oil The weight ratio is 3. The properties of catalytic heavy oil and solvent deasphalted oil are shown in Table 3.

[0064] Then adopt the process of hydrogenation upgrading to remove the colloids and asphaltenes, and the saturated part of polycyclic aromatic hydrocarbons. The hydrogenation unit is also a ...

Embodiment 2

[0073] According to the method of Example 1, light hydrocarbon oil is produced from hydrocarbon oil. The difference is that the reaction conditions and product distribution of catalytic cracking are as shown in Table 2, and the conditions of hydrogenation upgrading are: reaction pressure is 10.0MPa, volume space velocity 2.5h -1 , the reaction temperature is 410°C, and the volume ratio of hydrogen to oil is 800:1Nm 3 / m 3 . The properties of the products after hydrogenation upgrading are shown in Table 5. In the catalytic cracking medium-sized unit, the catalytic heavy oil after hydrogenation was tested in the catalytic cracking operation mode. The test operating parameters and product distribution are listed in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com