Production method of coal-based high-aromatic-hydrocarbon-potential-content naphtha for catalytic reforming, product and application thereof

A high-aromatic hydrocarbon, catalytic reforming technology, applied in the direction of naphtha catalytic reforming, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of unqualified catalytic reforming raw materials, no reference, etc., to avoid clogging, reduce Effects of equipment investment, land occupation, and strength reduction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention are provided below. It should be understood by those skilled in the art that the examples herein are for illustrative purposes only and should not be construed as limiting the scope of the invention defined by the claims in any way.

[0036] In a specific embodiment of the present invention, a method for directly liquefying crude liquefied oil from coal to produce naphtha with a very high potential content of aromatic hydrocarbons is provided, and the naphtha can be used as a feedstock for catalytic reforming.

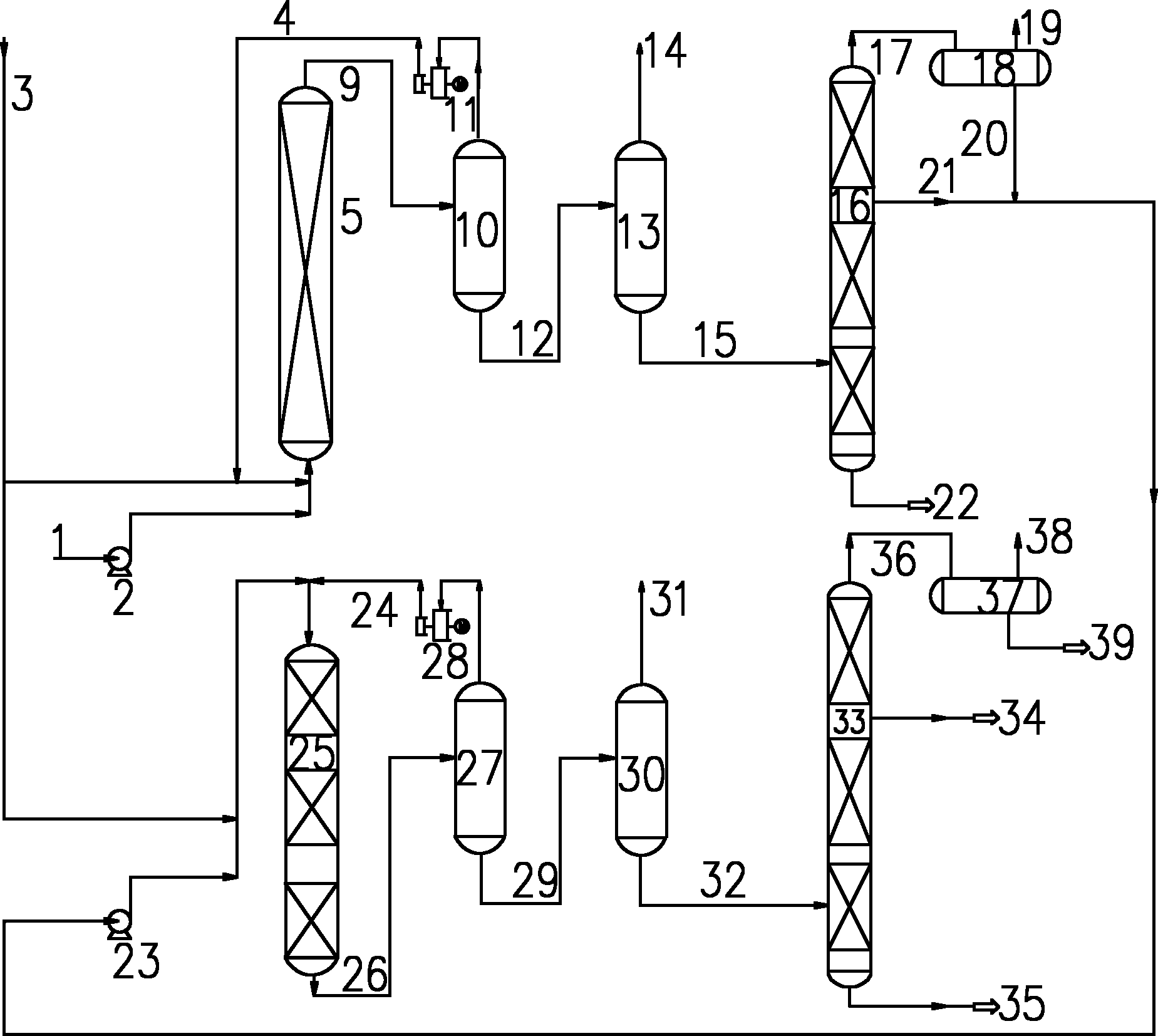

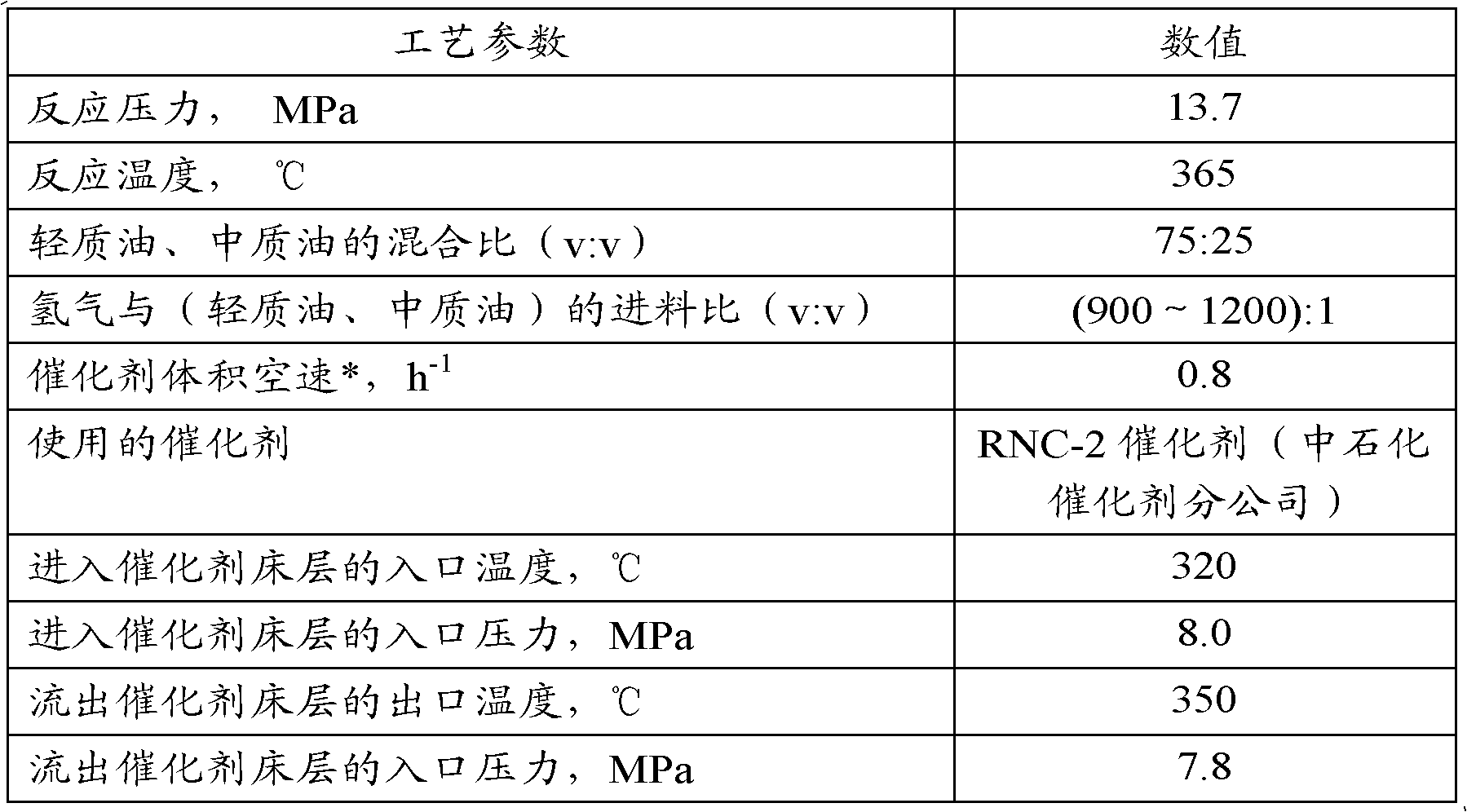

[0037] The method includes two steps of hydrotreating and deep hydrofining of crude liquefied oil:

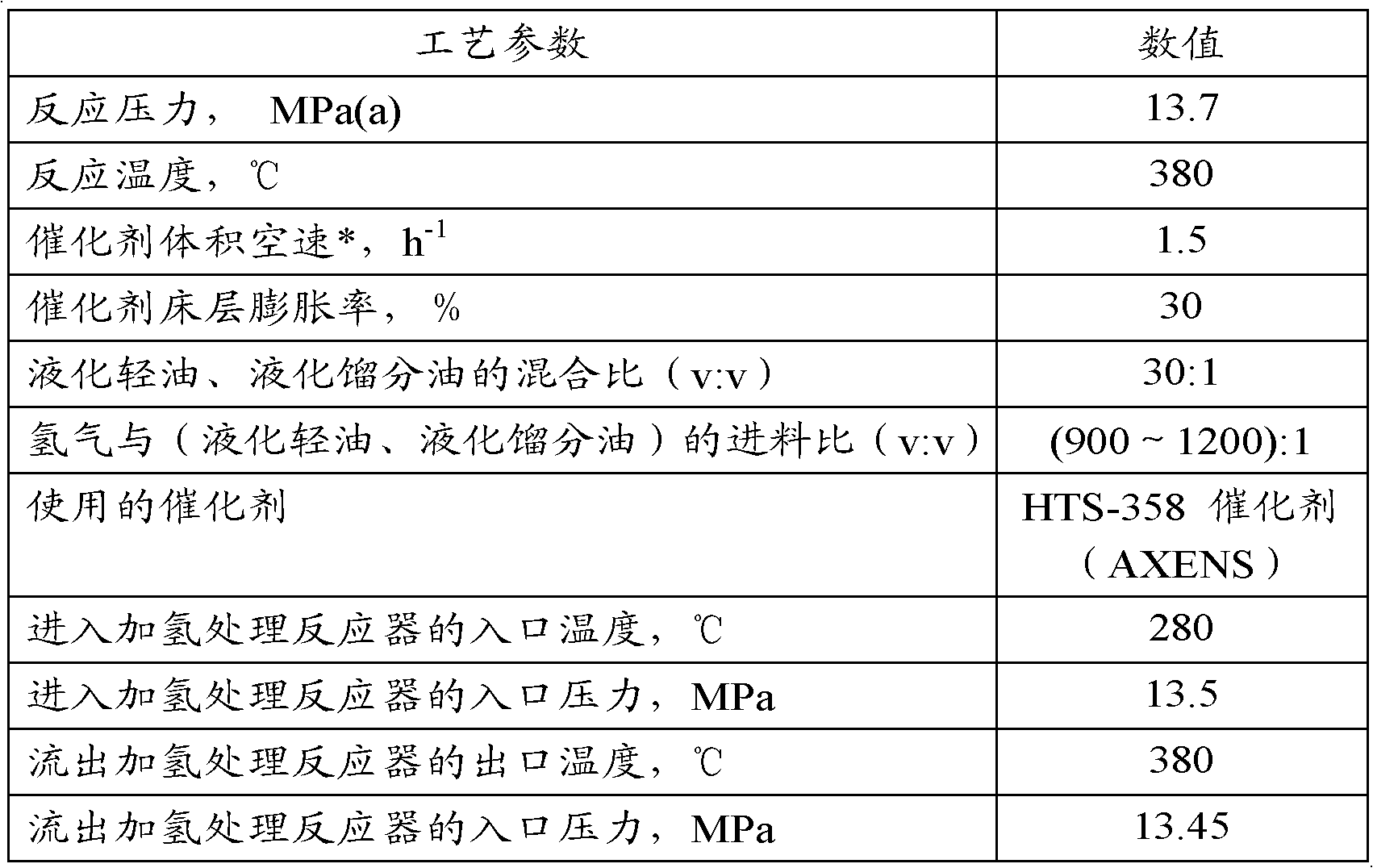

[0038] Step a): hydrotreating;

[0039] The purpose of hydrotreating is to saturate olefins, partially saturate aromatic hydrocarbons above two rings, and partially remove impurities such as oxygen, nitrogen, and sulfur in liquefied oil. On the one hand, it provides an active solvent for the direct coal liquefaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com