Biological stirring leaching method of ordinary-temperature acidophilic leaching-ore bacteria and high-arsenic high-grade primary copper sulfide ore

A stirring leaching and sulfide copper ore technology, which is applied in the field of leaching bacteria and refractory copper ore, can solve the problems of inability to obtain economic benefits, long flotation process, and refractory copper ore, so as to improve the comprehensiveness of mineral resources. Utilization level, high leaching capacity, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

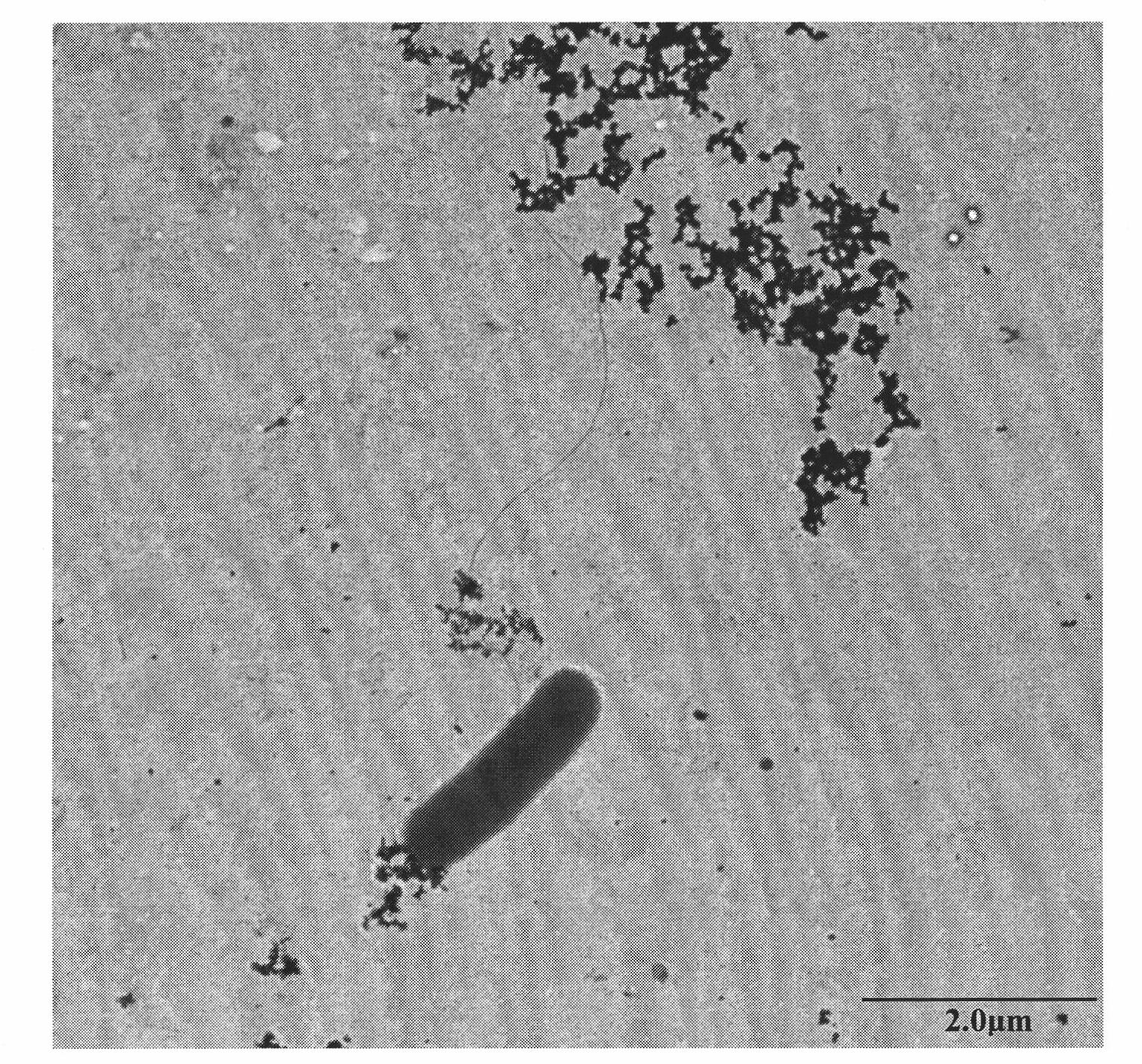

[0019] like figure 1 As shown, under the perspective electron microscope, the leaching bacteria (Thiobacillus ferrooxidans DBS02 CCTCC NO: M2010323) is rod-shaped, with round ends of the cells and long flagella on the sides. The size of the bacteria is 2-2.1 μm × 0.5-0.6 μm.

[0020] In this embodiment, mining is carried out first, and the ore is copper ore with high arsenic content. After crushing and fine grinding process, the particle size is controlled at particle diameter<0.18mm, and the pulp concentration is adjusted to 15-25% (g / ml) with water. 1+1 sulfuric acid adjusts the pH value of the ore pulp to be stable at 1.8 to 2.4, takes the supernatant to obtain a leaching solution, adds ferrous ions and the obtained leaching solution to the culture tank of Thiobacillus ferrooxidans DBS02, and expands the culture of acidophilic leaching bacteria. The obtained bacterial liquid and the obtained pulp are pumped into the biological stirring leaching system for biological stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com