Sandwiched mortar heat-insulating/warm-keeping block, preparation and application thereof

A technology of thermal insulation and mortar, applied in the field of building wall materials, can solve problems such as inconvenience of use, faults, affecting the use effect, etc., and achieve the effects of not easy to fall off, strong composite, and good thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

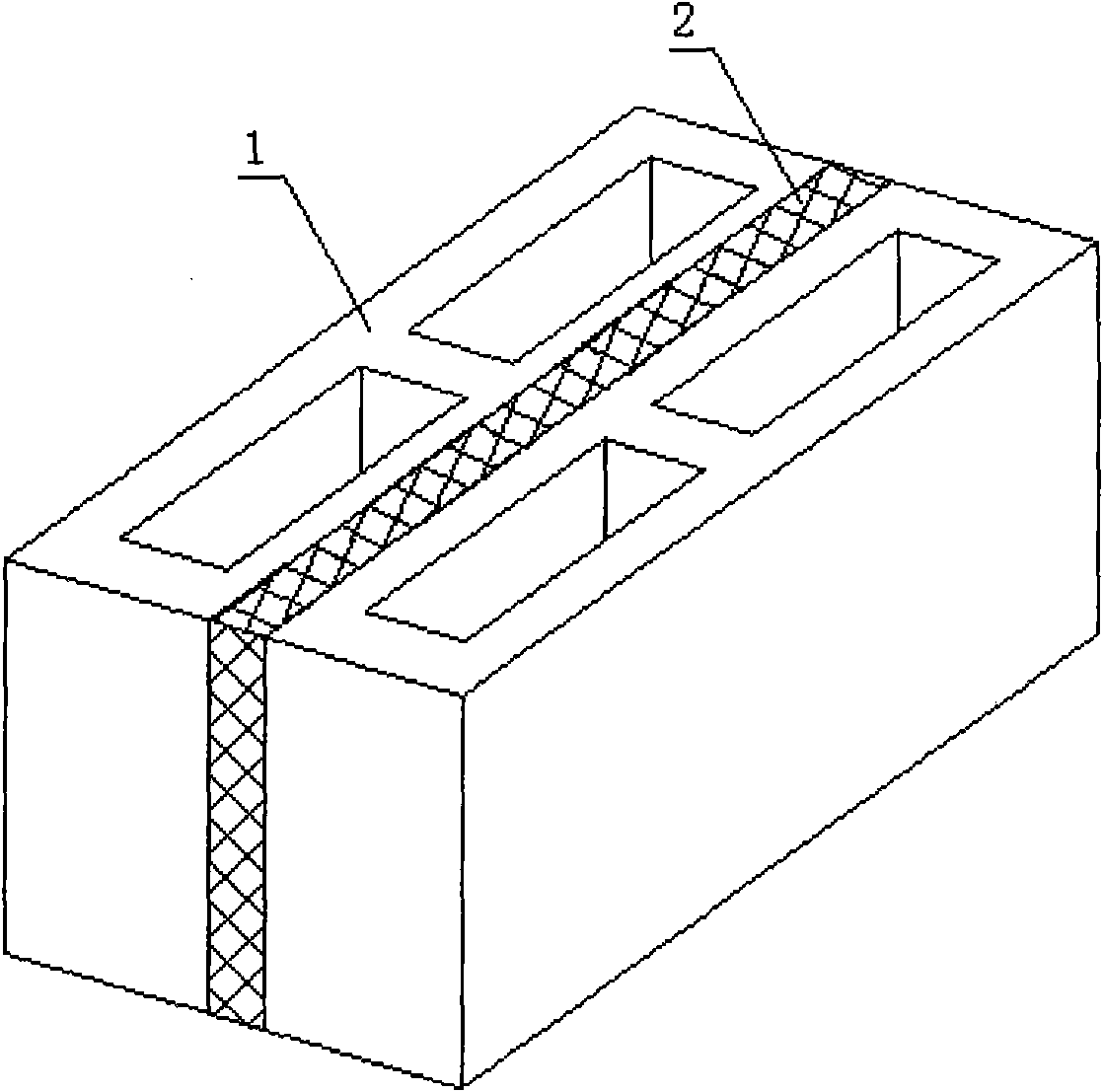

Image

Examples

Embodiment 1

[0035] Use the following methods to prepare thermal insulation blocks:

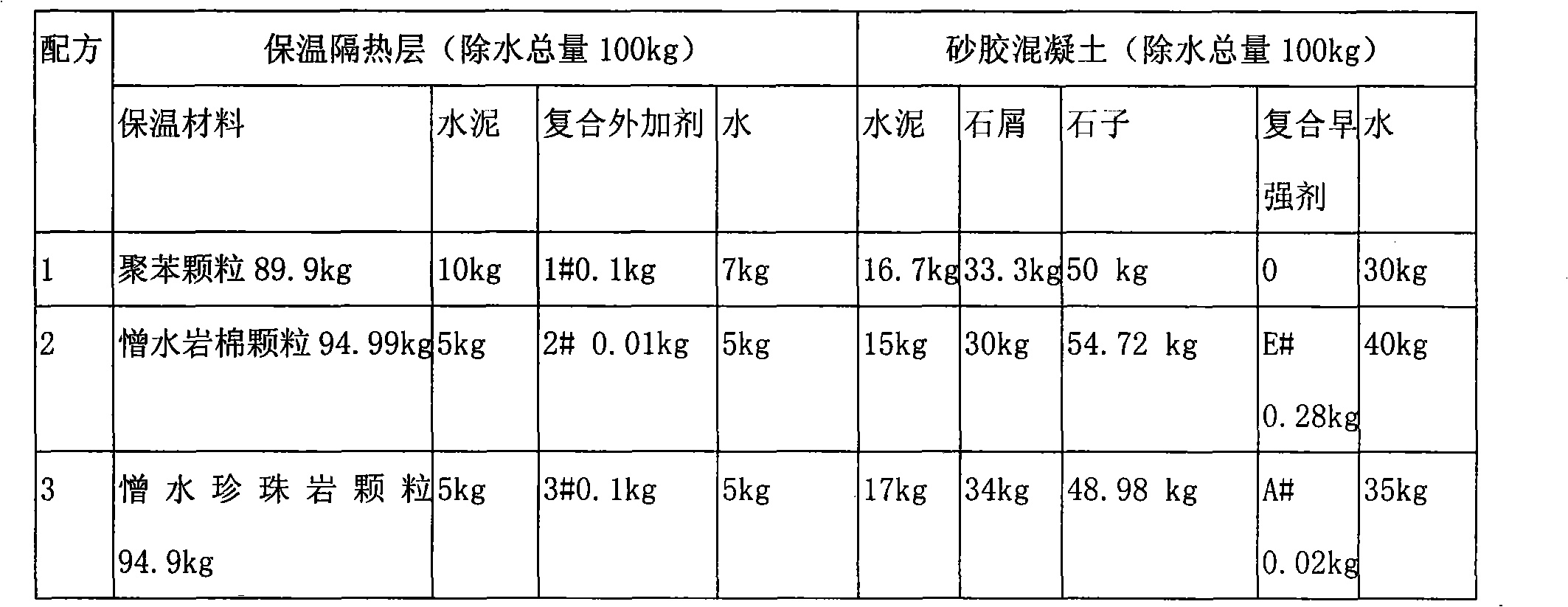

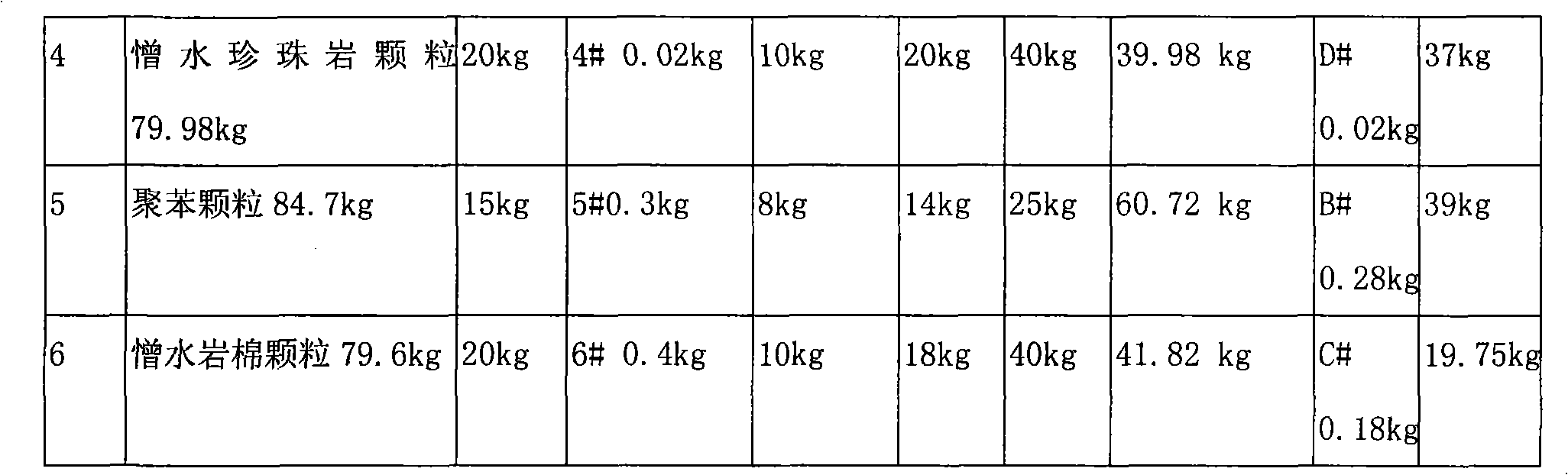

[0036] 1. Configuration of compound admixture: Prepare compound admixture according to the formula in Table 1.

[0037] Method: Heat and melt the rosin and mix it with plain water to form a milky state.

[0038] Table 1:

[0039] formula

Rosin wt%

Flat increase wt%

Water wt%

1#

17%

2%

81%

[0040] 2#

23%

2%

75%

3#

26%

2%

72%

4#

17%

5%

78%

5#

17%

9%

74%

6#

20%

7%

73%

[0041] 2. Preparation of compound early-strength agent: According to Table 2 formula, compound early-strength agent.

[0042] Table 2

[0043] formula

Triethanolamine wt%

Water wt%

A#

0.01%

0.1%

99.89%

B#

0.04%

1%

98.96%

C#

0.08%

0.5%

99.42%

[0044]

Sodium chloride / triethanolamine wt%

Dihydrate gypsum

Water wt%

D#

1%

Triethanolamine 0.05%

2%

96.95%

E#

1.7%

Sodium chloride 0.8%

2%

95.5%

[0045] 3. Preparation of thermal insulation laye...

Embodiment 2

[0053] Insulation effect test test:

[0054] Make a 300cm×300cm×30cm test block to test its thermal conductivity, the results are shown in Table 4

[0055] Table 4

[0056]

Embodiment 3

[0058] Test of bonding firmness between interlayer and mortar concrete:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com