Chain grate machine of dry distillation oil shale

A technology of grate machine and retort oil, which is applied in special retort, petroleum industry, furnace, etc. It can solve the problems of poor sealing performance of head and tail, increase fan energy consumption, large gas flow, etc., and achieve improved heat transfer effect , Reduce the scale of initial investment, reduce the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

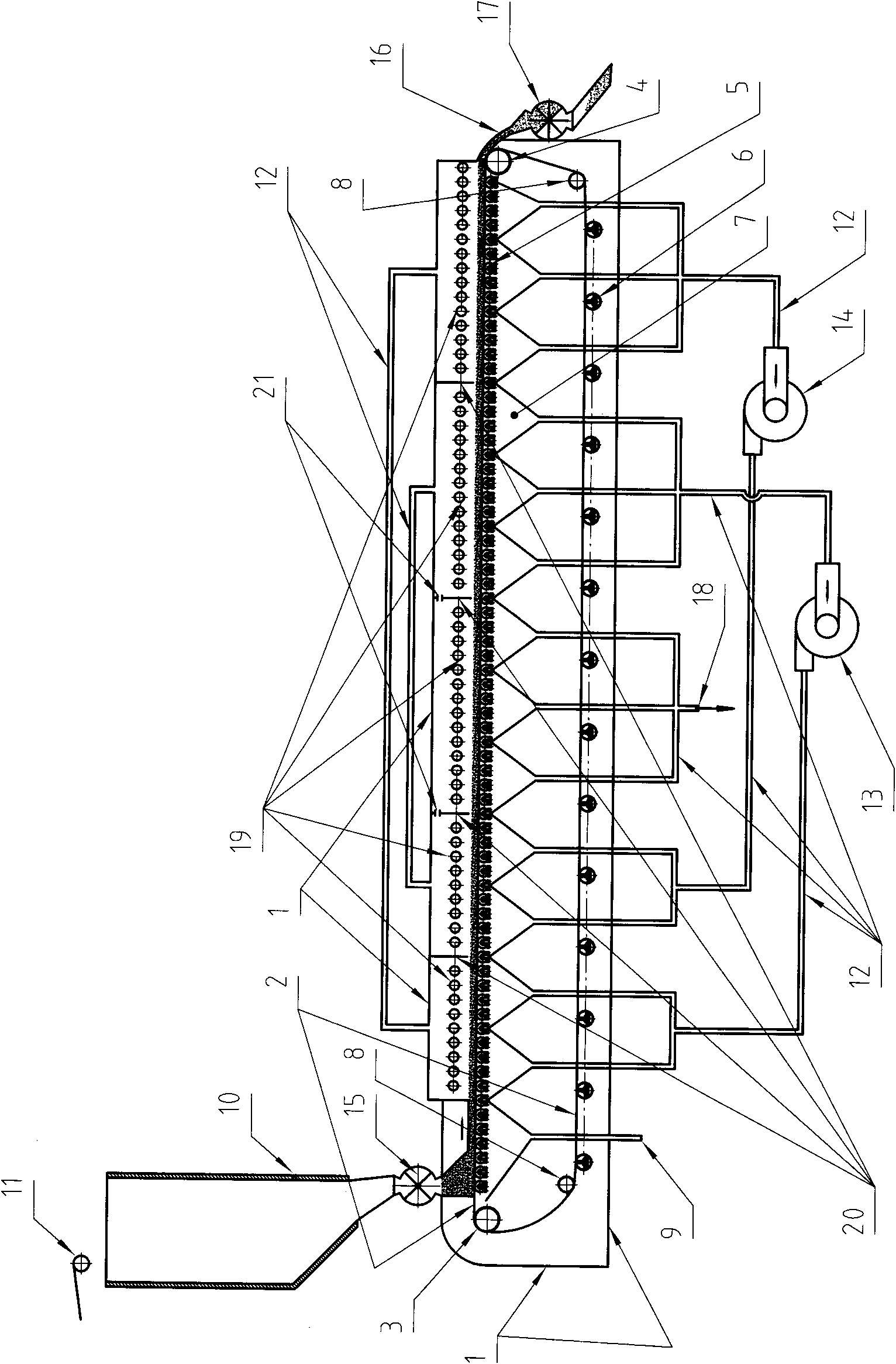

[0038] Example 1, such as figure 1 shown.

[0039] exist figure 1 In the shown embodiment 1 of the chain grate machine of the present invention, 1 is a wind cover, and the wind cover contains all the chain grate bodies 2 . The grate body 2 is a chain assembly including a grate plate. 3 is the head wheel. 4 is tail wheel. 5 is the upper idler. 6 is lower idler. 7 is a bellows. In terms of the structure of the bellows, if necessary, reference can also be made to the structure of a sintering machine and / or a bellows with a cooler. 8 is a pinch wheel. The 9th is the leaking material collection box, and the effect of this collection box is to collect and discharge the powder that leaks down from the chain device in the feeding section. This chain grate machine is also provided with driving device (not shown in the figure), is used for the driving of chain grate body 2. Except that the head wheel 3 and / or the tail wheel 4 can be set as driving rollers, part or even all of...

Embodiment 2

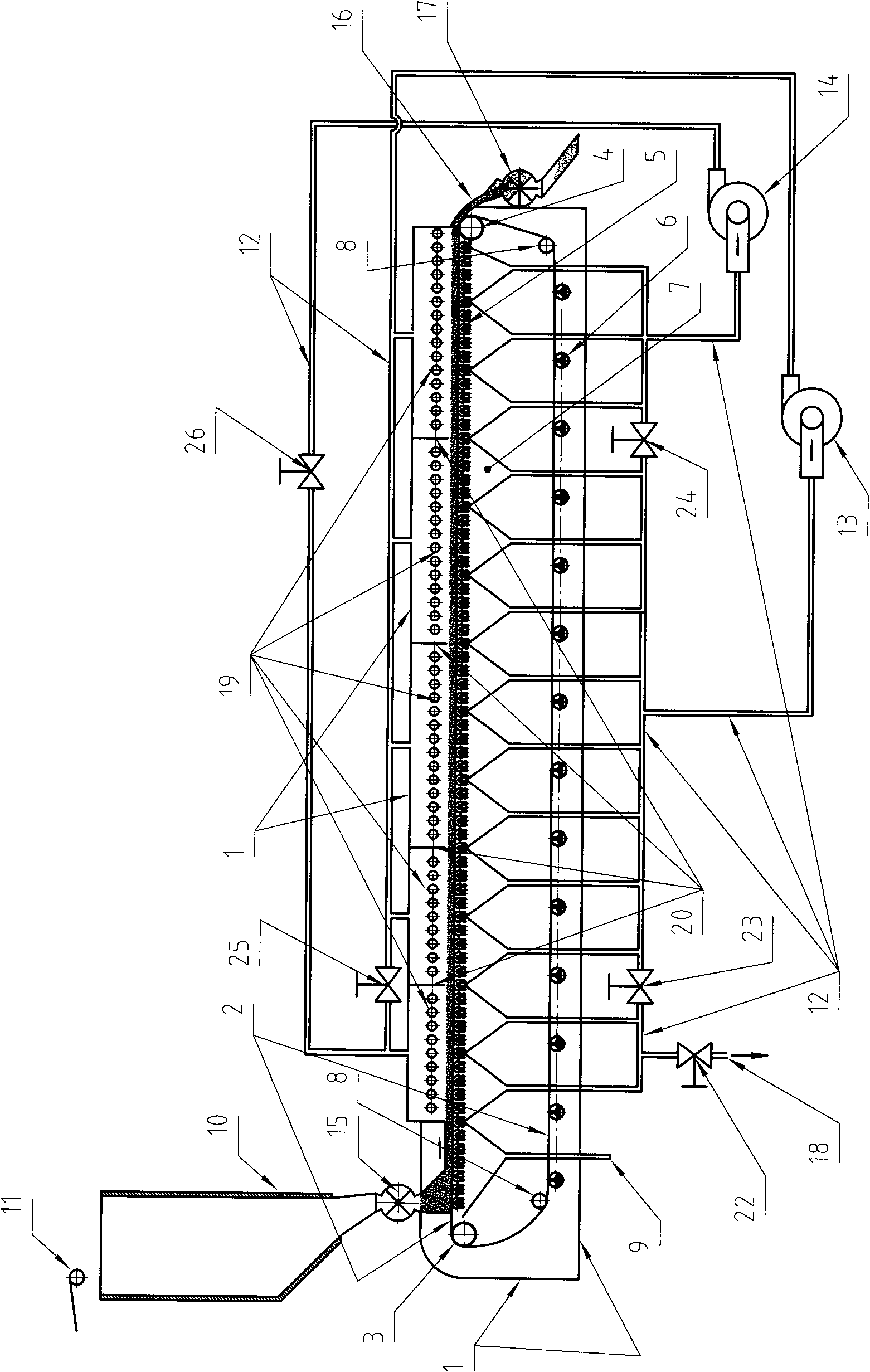

[0042] Example 2, such as figure 2 shown.

[0043] This embodiment is an improvement on the basis of Embodiment 1.

[0044] exist figure 2 In the shown embodiment 2, in addition to changing the communication relationship and direction of the pipeline 12, valves 22, 23, 24, 25 and 26 are added; at the same time, the air passage hole 21 in embodiment 1 is canceled; the remaining , then the same as in Example 1.

[0045] By adjusting the opening of the valve 22, the delivery volume of shale oil and gas can be adjusted; when the valves 23, 24, and 25 are opened, the valve 26 is closed and the operation of the fan 14 is stopped, it enters the cycle operation state of a single fan; After closing the valves 23, 24, 25, opening the valve 26 and starting the blower fan 14, it enters the running state of the double blower fans. Furnace gas is sent to the heating chamber on the far left. On the one hand, since the raw material oil shale that has just entered the furnace has a relat...

Embodiment 3

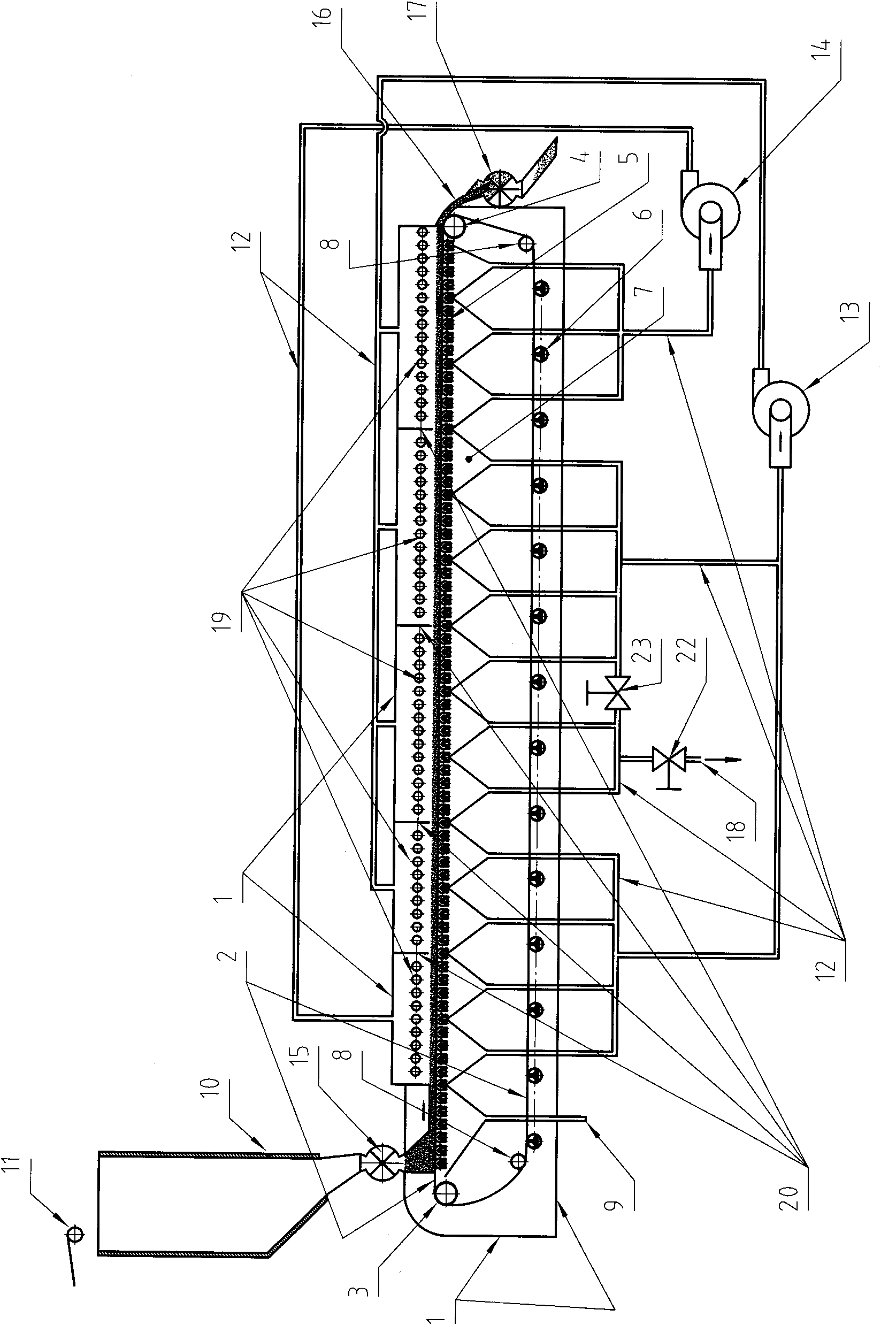

[0047] Example 3, such as image 3 shown.

[0048] This embodiment is a change made on the basis of Embodiment 2.

[0049] exist image 3 In the shown embodiment 3, in addition to changing the communication relationship and direction of the pipeline 12, the function of the valve 23 to adjust the return air volume is also retained. The purpose of adjusting the output port 18 of the furnace gas to the middle is to meet the needs of the next process for shale oil and gas to be treated at a higher temperature under certain conditions. The rest can be interpreted by readers themselves.

[0050] One of the basic purposes of listing this embodiment is also to show that the arrangement of fans and pipelines for circulating furnace gas through the oil shale layer has high flexibility and diversity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com