Manufacturing method of SiGe heterojunction bipolar transistor

A technology of heterojunction bipolar and fabrication method, applied in semiconductor/solid-state device manufacturing, semiconductor device, electrical components and other directions, can solve the problems of complex process and complex process, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

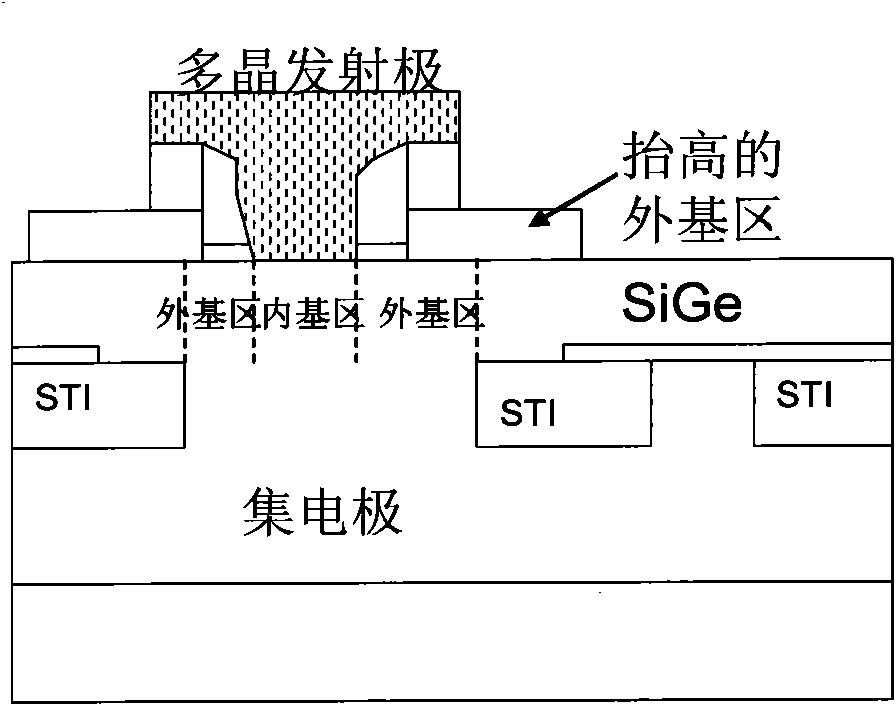

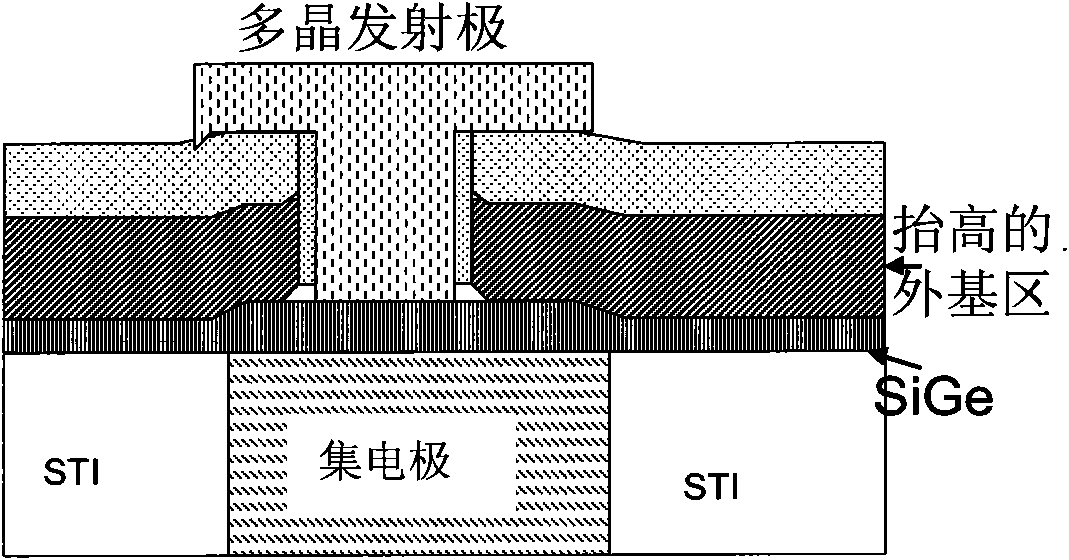

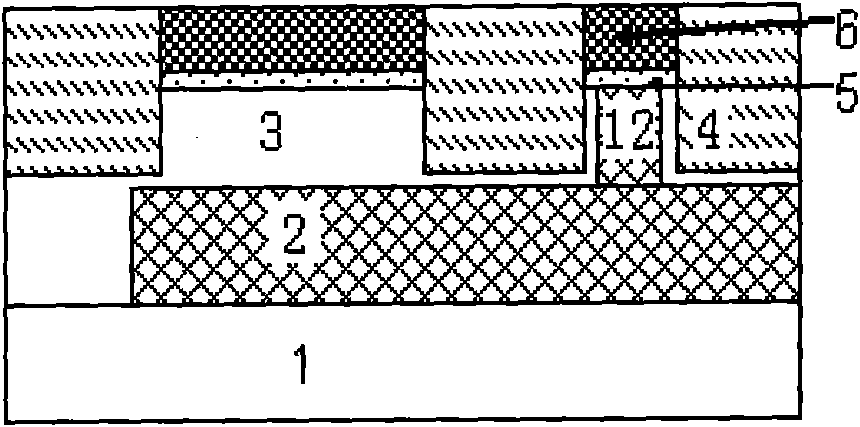

[0034] The invention discloses a manufacturing method of a germanium-silicon heterojunction bipolar transistor (HBT, heterojunction bipolar transistor) with an elevated extrinsic base region and self-alignment between the extrinsic base region and the emitter, which combines the shallow trench isolation process module The materials and processes used in the above are to form highly doped P-type polysilicon that increases the outer base region, and then use the selective epitaxy process to form the inner base region of the germanium-silicon heterojunction bipolar transistor region, and finally use the dielectric film as the emitter The isolation layer between the electrode and the extrinsic base region, and the emitter electrode is deposited.

[0035] The device main technology of a heterojunction bipolar transistor (NPN) is taken as an example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com