Recycling utilization method of tea leafs

A technology of tea dregs and extraction water, which is applied in the field of plant extraction and processing, can solve the problems of large amount of extraction agent, serious environmental pollution, and low utilization efficiency, and achieve easy control of operating conditions, short process flow, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

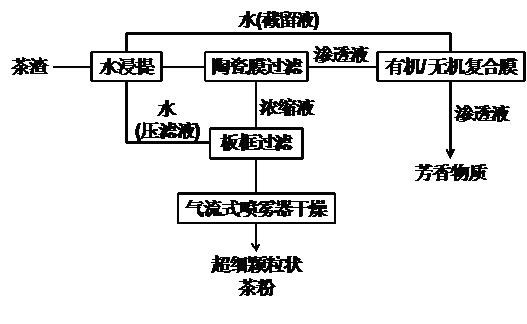

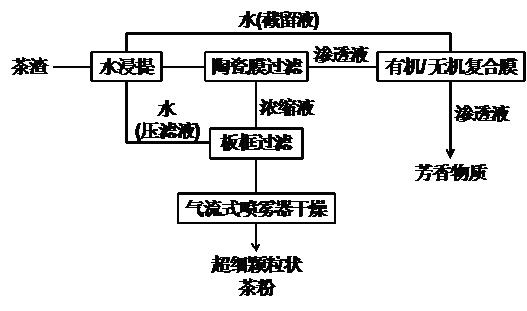

Image

Examples

Embodiment 1

[0028] Prepare the powdered tea residue and water by mechanical crushing at a mass ratio of 1:20, extract at 50°C for 100 minutes, filter the extract with a 10 nm alumina ceramic filter membrane, and control the operating temperature at 10°C , pressure 4×10 5 Pa, the membrane surface velocity is 5 m / s, and the steady flux is maintained at 60 L / (m 2 h), after the retentate is concentrated 80 times, it is put into a plate and frame filter press of 300 mesh filter cloth for pressure filtration, wherein the filter cake is dried by an airflow sprayer to obtain tea powder, and the filter press liquid is returned to the extraction process for recycling, Ceramic membrane filtration permeate liquid does not contain solid particles, using PDMS / alumina ceramic composite membrane for separation, the operating conditions are temperature 20°C, pressure 1300 Pa, and the permeability of aromatic substances is 2.3×10 -3 Kg / m -2 h, the yield of aromatic substances measured by gas chromatog...

Embodiment 2

[0030] Prepare the powdered tea residue and water by mechanical pulverization according to the mass ratio of 1:20, extract at 50°C for 60 minutes, filter the extract with a 20 nm zirconia ceramic membrane, and control the operating conditions at a temperature of 20°C. Pressure 0.5×10 5 Pa, the membrane surface velocity is 3 m / s, and the steady flux is maintained at 80 L / (m 2 h), after the retentate is concentrated 80 times, it is put into a plate and frame filter press of 300 mesh filter cloth for pressure filtration, wherein the filter cake is dried by an airflow sprayer to obtain tea powder, and the filter press liquid is returned to the extraction process for recycling, Ceramic membrane filtration permeate liquid does not contain solid particles, using POMS / zirconia ceramic composite membrane for separation, the operating conditions are temperature 5°C, pressure 60 Pa, and the permeability of aromatic substances is 2.5×10 -5 Kg / m -2 h, the yield of aromatic substances ...

Embodiment 3

[0032] The powdered tea dregs and water made by mechanical crushing were configured according to the mass ratio of 1:20, extracted at 75°C for 75 minutes, and the extract was filtered with a 50 nm titanium oxide ceramic membrane, and the operating conditions were controlled at a temperature of 5°C. Pressure 2.4×10 5 Pa, the membrane surface velocity is 2 m / s, and the steady flux is maintained at 78 L / (m 2 h), after the retentate is concentrated 80 times, it is put into a plate and frame filter press of 300 mesh filter cloth for pressure filtration, wherein the filter cake is dried by an airflow sprayer to obtain tea powder, and the filter press liquid is returned to the extraction process for recycling, Ceramic membrane filtration permeate clear liquid does not contain solid particles, using PEBA / titanium oxide ceramic composite membrane for separation, the operating conditions are temperature 40 ℃, pressure 3500 Pa, the permeability of aromatic substances is 8.9×10 -3 Kg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com