Method for preparing walnut polypeptide beverage

A beverage preparation method, walnut polypeptide technology, applied in food preparation, application, food science, etc., can solve problems such as complex production process, no walnut polypeptide beverage preparation process, increase product cost, etc., to solve precipitation and shorten high-temperature heating Time, enhance the effect of embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

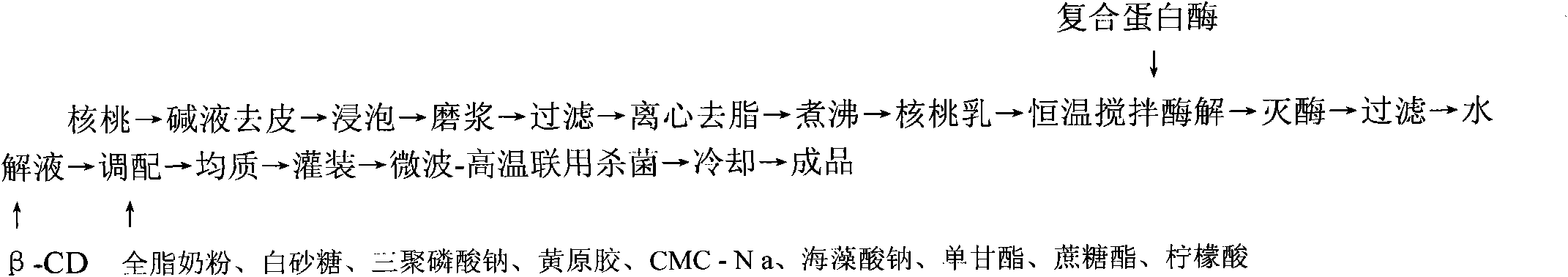

[0024] Embodiment one: the preparation of walnut polypeptide drink

[0025] 1. Pretreatment: Soak in 1% NaOH solution at 65°C for 10 minutes, rinse with water repeatedly, and remove walnut kernel skin.

[0026] 2. Refining: Soak the peeled walnut kernels at room temperature for 12 hours, the ratio of material to liquid is 1:12, the temperature of the refining water is 60°C, then finely grind with a colloid mill, separate the pulp and residue, filter and boil the slurry for 5 minutes to make the raw material Moderate thermal denaturation of the protein in the medium will loosen the molecular structure and greatly increase the action point of enzymatic hydrolysis, which will help to speed up the speed of enzymatic hydrolysis and improve the degree of protein hydrolysis.

[0027] 3. Enzymolysis: Enzymolysis under set conditions, the ratio of alkaline protease to flavor protease is 2:1, and lactic acid or 1mol / L NaHCO is added dropwise during the reaction process 3 The solution w...

Embodiment 2

[0031] Example 2: Determination of enzymatic hydrolysis conditions in the preparation process of walnut polypeptide beverage

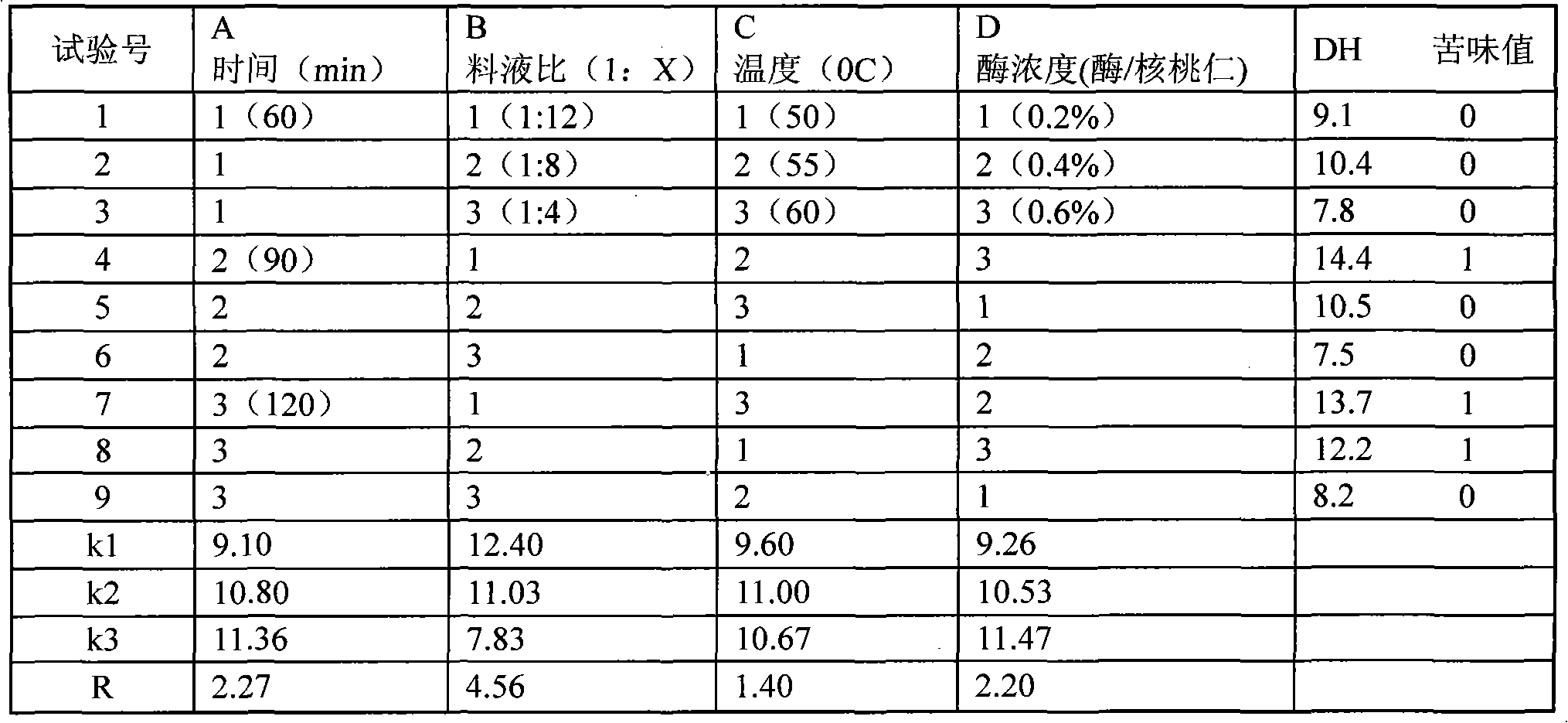

[0032] Use L 9 (3 4 ) Orthogonal experiment to optimize the optimum conditions for the enzymolysis reaction, taking the degree of hydrolysis (DH) and the bitterness value of the enzymatic hydrolyzate as the evaluation indicators. Orthogonal experiment design and results are shown in Table 1.

[0033] Orthogonal experiment result L of enzymatic hydrolysis condition of table 1 9 (3 4 )

[0034]

[0035]

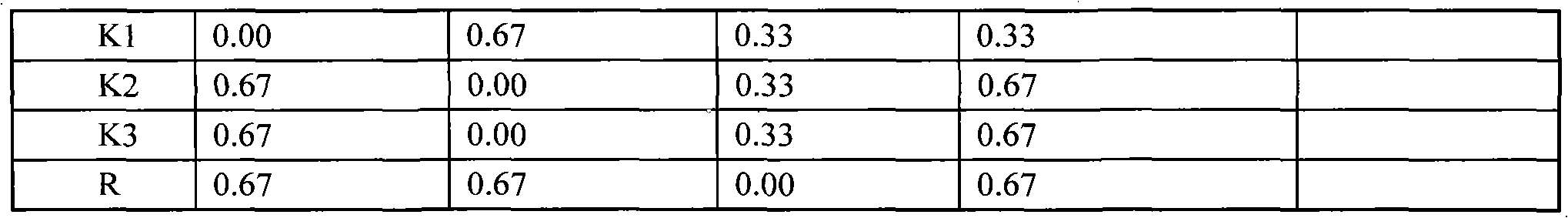

[0036] The variance analysis result of table 2 enzymolysis

[0037]

[0038] It can be seen from Table 1 that the primary and secondary order of the influence of the four factors on the degree of hydrolysis is substrate concentration > time > enzyme amount > temperature, and the best combination is A 3 B 1 C 2 D. 3 , that is, the ratio of material to liquid is 1:12, the temperature is 55°C, the enzyme concentration (enzyme / walnut kerne...

Embodiment 3

[0041] Example 3: Selection of debittering conditions for hydrolyzate in the preparation process of walnut polypeptide beverage

[0042]Since the protein produces bitter taste after enzymatic hydrolysis, which is not conducive to the taste of the product, debittering treatment is required. In this test, according to the quality requirements of the product, the embedding method was used to remove bitterness. β-CD was initially selected as a bitter embedding agent. With the addition of 1.5% β-CD, the walnut polypeptide hydrolyzate was stirred at 45°C for 30 minutes, and there was basically no bitter taste.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com