Multi-station cold heading manufacturing method for plate die adjusting seat blank

An adjustment seat and multi-station technology, which is applied in the direction of metal processing equipment, etc., can solve the problems of loose crystal structure arrangement, large lathe processing volume, product cracking or cracking, etc. The effect of excellent mechanical properties and reduced loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

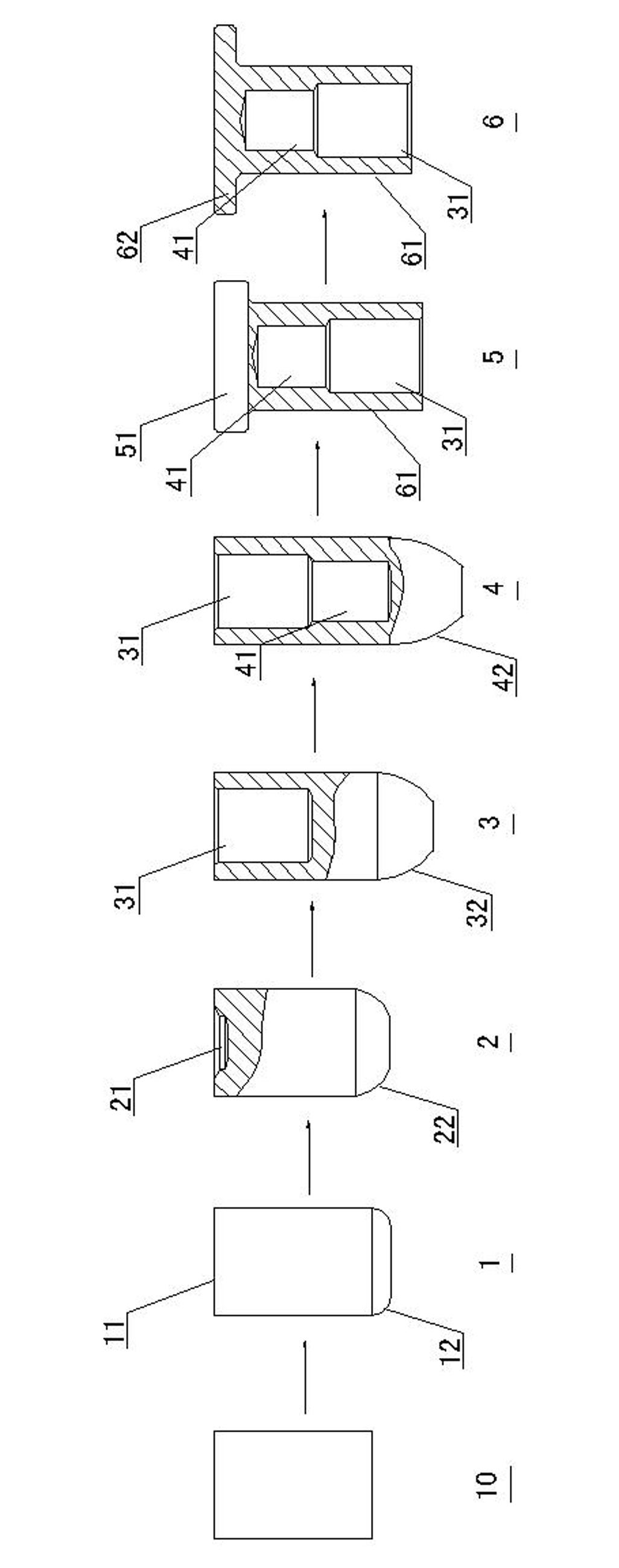

[0033] Embodiment 1, with reference to figure 1 , 3 .

[0034] In the present invention, the round wool is used as the raw material. Firstly, the round wool is treated with a phosphate film surface treatment, and then the wool after the surface treatment of the phosphate film is fine-drawn and sized to be a round finished material. After fine-drawing and sizing, The disc round finished material is cut into a single plate mold adjustment seat material 10; then the following cold extrusion processing is also provided:

[0035] A. Upsetting an arc angle at one end of the material, and then through one to three cold headings to gradually increase the radius of the arc angle, and then cold heading this end into a flat plate for the plate mold adjustment seat The blank shape of the part, when the blank shape of the flat plate part is formed by cold heading, the length of the plate mold adjustment seat is shortened,

[0036] B. For the other end of the material, three to five hole...

Embodiment 2

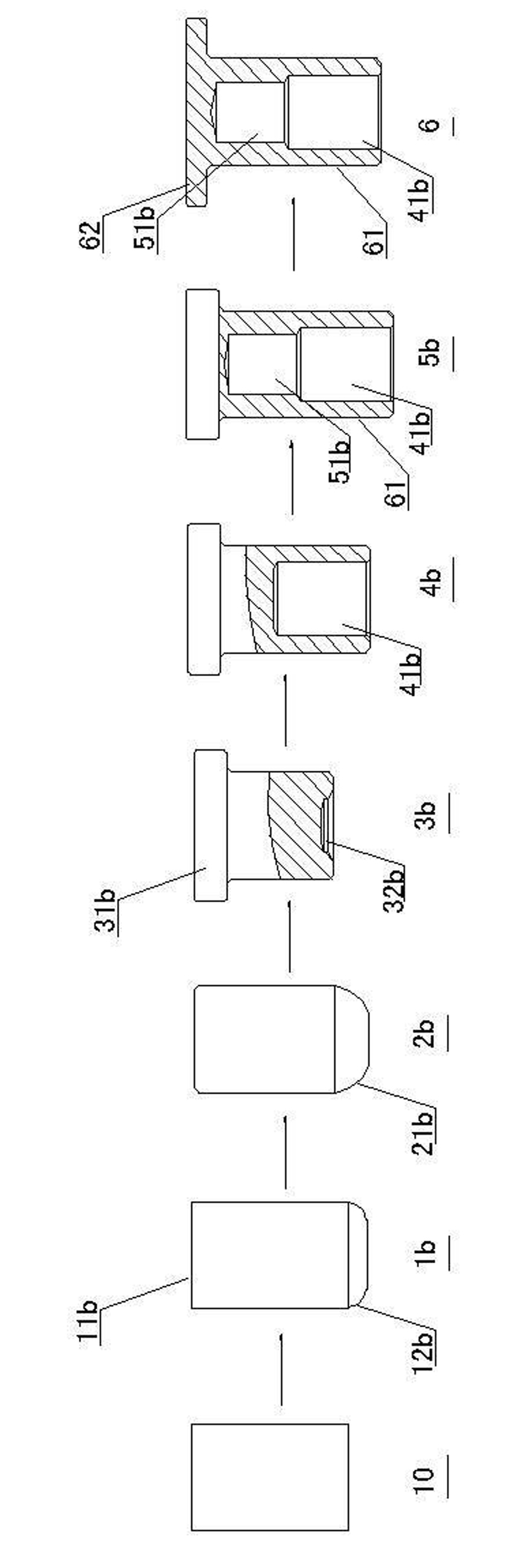

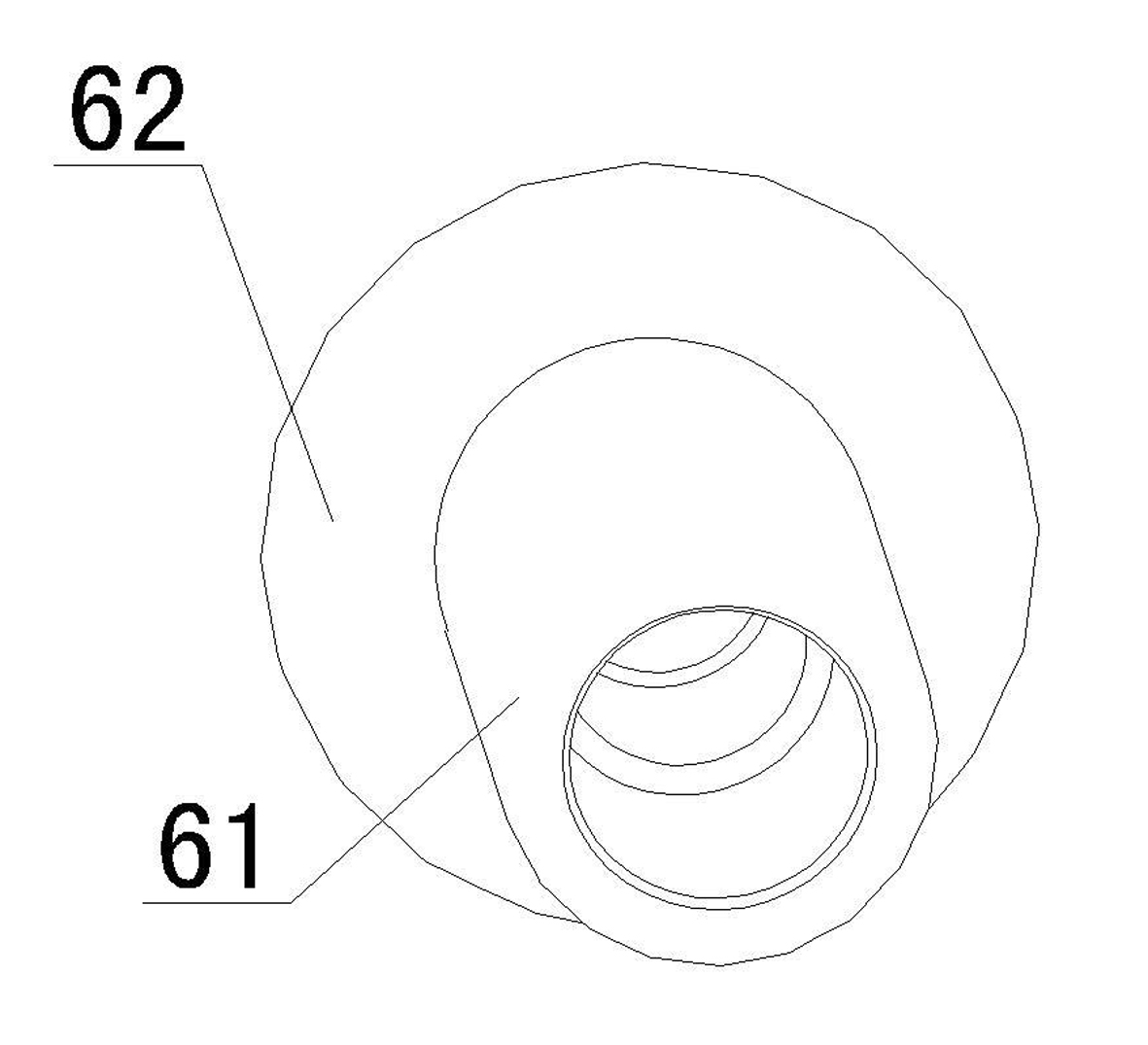

[0045] Embodiment 2, with reference to figure 2 , 3 .

[0046] In this embodiment, the cold extrusion treatment A and the cold extrusion treatment B are carried out in corresponding stations according to the following sequence of stations. figure 2 , the reference numbers are the same as figure 1 The same means the same meaning.

[0047] The first station: level the front end 11b of the material, and upset the arc angle 12b at the rear end of the material to elongate the total length of the material; the reference number 1b is the plate mold adjustment seat material after the first station is completed .

[0048] The second station: the rear end of the material is upset on the basis of the first station to form an arc angle 21b with a larger radius to elongate the total length of the material; the reference number 2b is the plate after the second station Die adjustment seat material.

[0049] The third station: Turn the material over 180°, cold extrude the material, cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com