Method for manufacturing diamond tool with self-lubrication function

A diamond tool and functional technology, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of reduced grinding efficiency, diamond thermal damage, shedding, etc., to reduce the heat generated by grinding, reduce the grinding temperature, Improves the effectiveness of the lubricating behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: a kind of manufacture method with self-lubricating function diamond tool, comprises the following steps:

[0015] (1) Add graphite particles with lubricating function to the Ni-Cr alloy; the content of graphite particles accounts for 2~20% of the total mass of the solder;

[0016] (2) Stir the mixture of Ni-Cr alloy and graphite particles evenly to form the solder for brazing diamond tools;

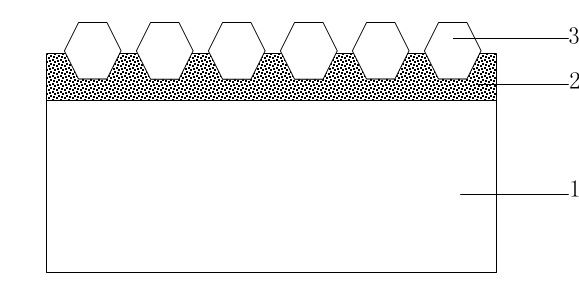

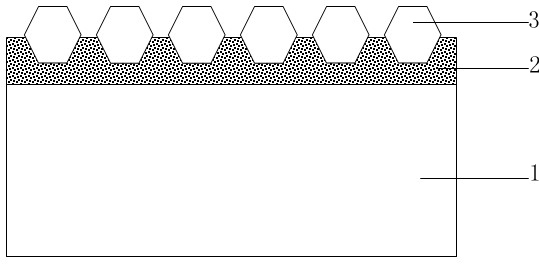

[0017] (3) if figure 1 As shown, diamond tool forming blanks are made in the order of diamond tool metal substrate 1, brazing filler metal 2, and diamond abrasive grains 3;

[0018] (4) Put the diamond tool forming blank into the heating furnace, adopt the brazing process, the heating temperature is 900~1100°C, and keep it warm for 1~20 minutes, so that the Ni-Cr alloy can chemically react with the graphite particles and diamond abrasive particles respectively. A diamond tool with self-lubricating function is produced.

[0019] The brazing method is a vacuum brazin...

Embodiment 2

[0021] Embodiment 2: A kind of manufacture method with self-lubricating function diamond tool, Ni-Cr alloy selects Ni-Cr-B-Si alloy for use, wherein Cr 17%, B 3.5%, Si 4.0%, C is 1%, Fe< 5.0%, and the balance is Ni. The diameter of graphite particles is 10 μm, and its mass accounts for 4% of the total mass of solder. The brazing filler metal (Ni-Cr-B-Si alloy and graphite particles) is mechanically stirred for 10 minutes, and the tool blank is made in the order of diamond tool steel substrate, brazing filler metal, and diamond abrasive grains, and the diamond tool substrate material is a steel substrate. Put the tool blank into the heating furnace, and carry out vacuum protection brazing at 1010°C for 1 minute, so that the Ni-Cr-B-Si alloy containing graphite particles and the diamond undergo a chemical reaction, and then cool to room temperature with the furnace.

[0022] Others are with embodiment 1.

Embodiment 3

[0023] Embodiment 3: A kind of manufacture method with self-lubricating function diamond tool, Ni-Cr alloy selects Ni-Cr-B-Si alloy for use, wherein Cr 17%, B 3.5%, Si 4.0%, C is 1%, Fe< 5.0%, and the balance is Ni. The diameter of graphite particles is 10 μm, and its mass accounts for 6% of the total mass of solder. The brazing filler metal (Ni-Cr-B-Si alloy and graphite particles) is mechanically stirred for 10 minutes, and the tool blank is made in the order of the diamond tool metal matrix, brazing filler metal, and diamond abrasive grains. The diamond tool matrix material is a steel matrix. Put the tool blank into the protection device, and perform induction brazing at 1030°C for 30 seconds, so that the Ni-Cr-B-Si alloy containing graphite particles and diamond undergo a chemical reaction, and cool to room temperature to take out the sample.

[0024] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com