Non-contact-type ultrasonic-assisted laser welding method

An auxiliary laser, non-contact technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of joint softening, easy generation of pores, thermal cracks, etc., to avoid pores, improve efficiency, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

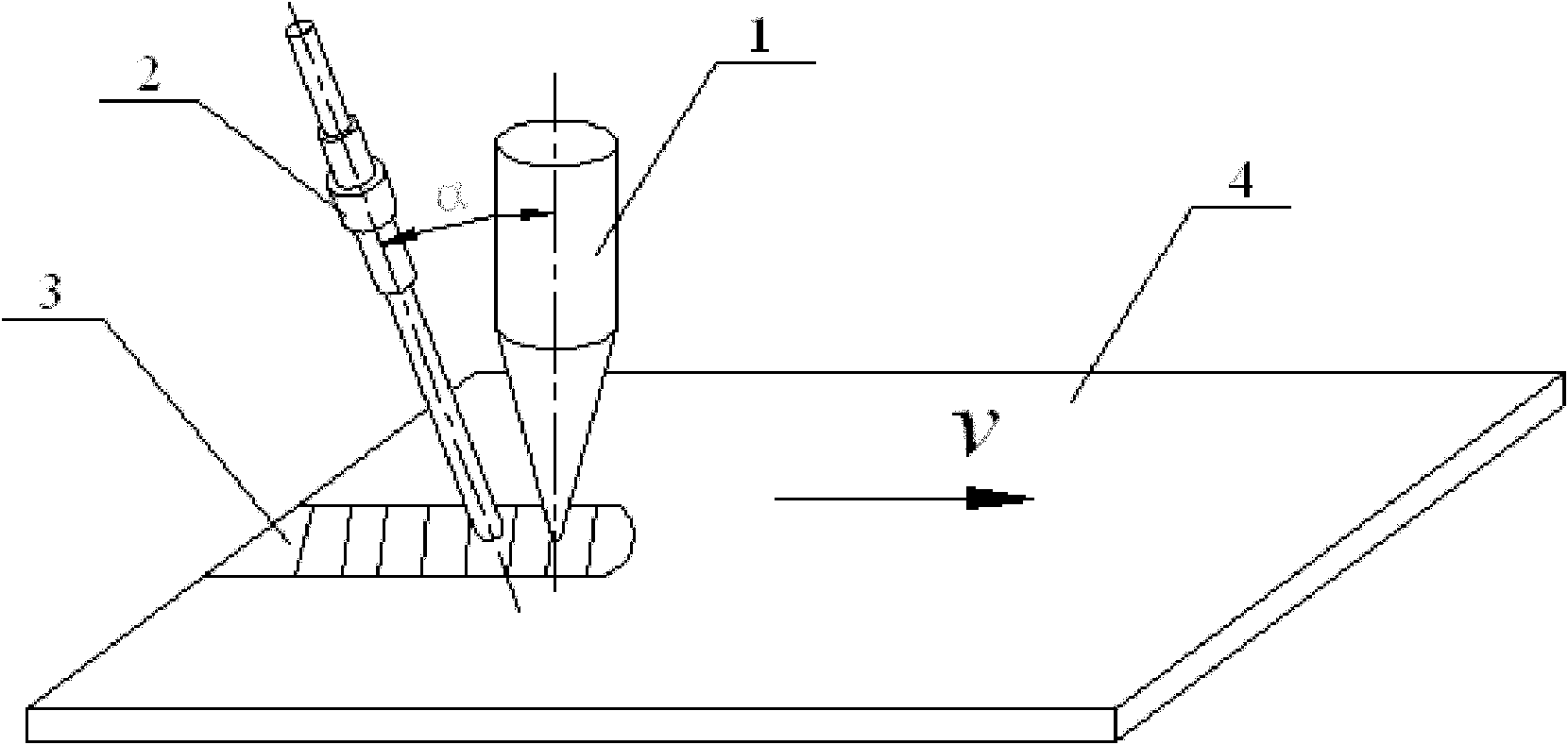

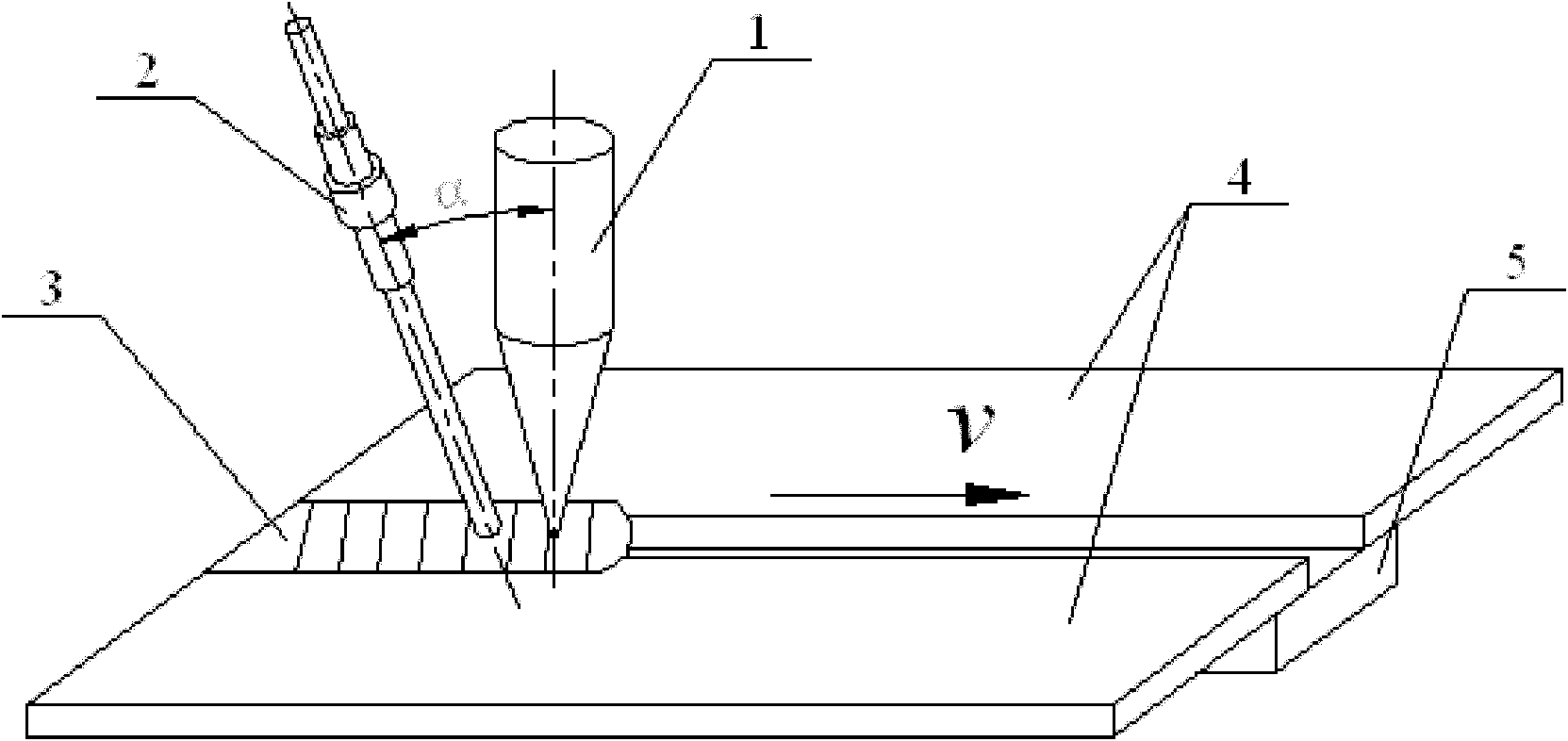

[0013] Specific embodiment one: the method for ultrasonic non-contact assisted laser welding in this embodiment is carried out according to the following steps:

[0014] 1. Treat the surface of the metal workpiece to be welded until the bright metal color is exposed on the surface to be welded. The metal workpiece to be welded is titanium alloy or aluminum alloy;

[0015] 2. Carry out the joint connection of the metal workpiece to be welded which has been processed in step 1, and rigidly fix it;

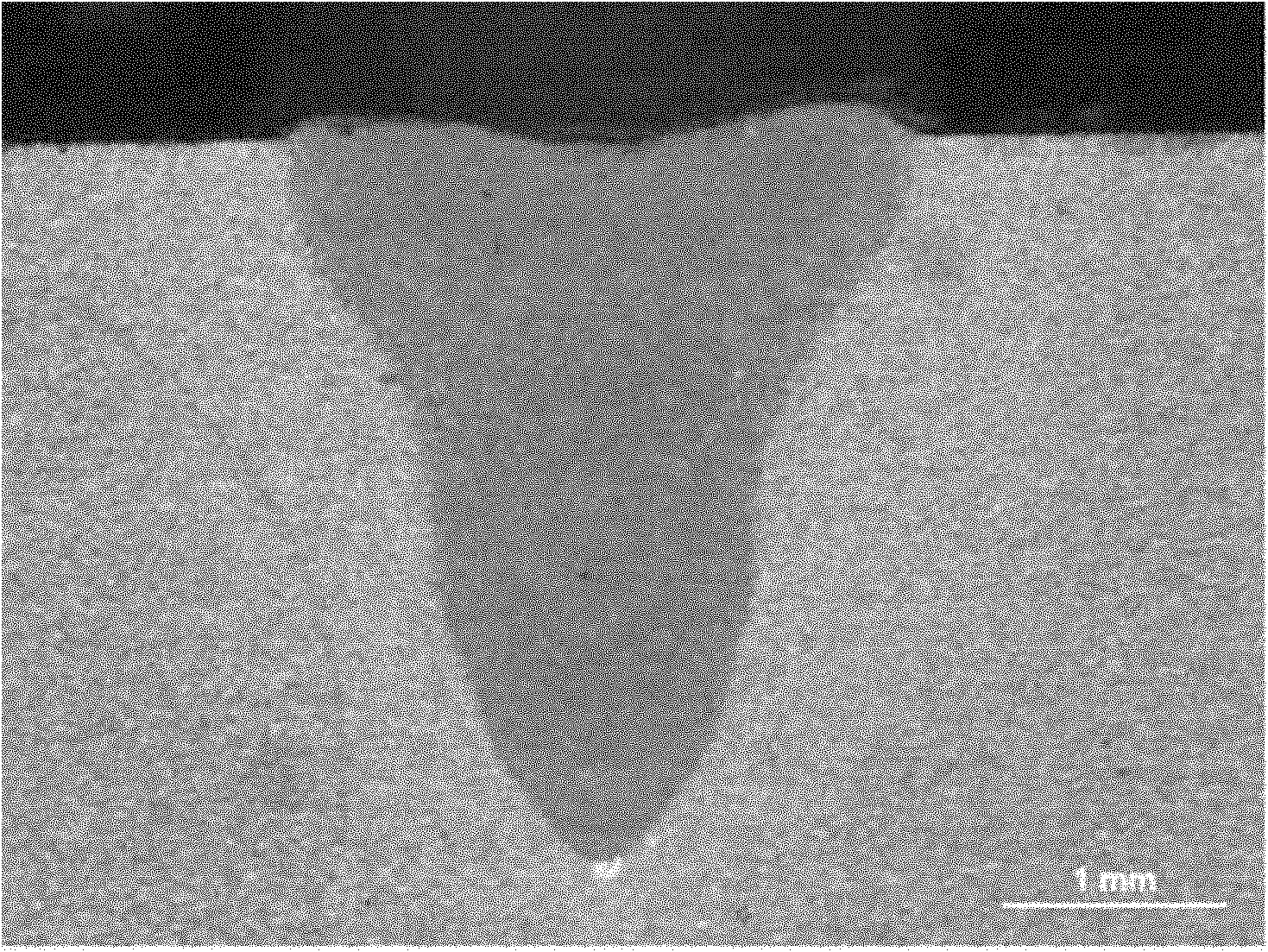

[0016] 3. Then use argon as protective gas, CO 2 The laser is used as a laser source for laser welding, and ultrasonic waves are applied to the molten pool generated by laser welding during the welding process. The ultrasonic waves are generated by a power ultrasonic generator placed in the air, and the lowest end of the ultrasonic horn of the ultrasonic generator does not touch The metal workpiece to be welded, and the ultrasonic horn of the ultrasonic generating device is inclined...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that: the joint connection method described in step 2 is lap joint or deep penetration welding. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the angle a between the ultrasonic horn of the ultrasonic generating device and the laser beam in step 3 is 35°-55°. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com