Method for integrally extracting levamisole hydrochloride by continuous distillation and drum crystallization

A technology for levamisole hydrochloride and crystallization, which is applied in the field of continuous rectification and drum crystallization integrated extraction of levamisole hydrochloride, can solve the problems of poor quality stability, high energy consumption, difficult control of crystallization process, etc., and achieves simple operation, high yield, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

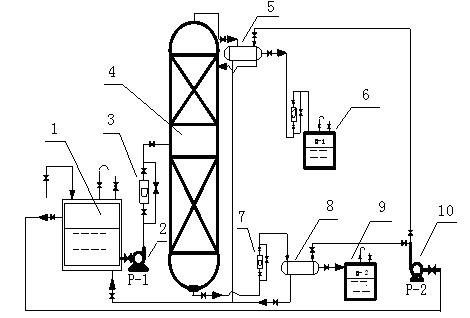

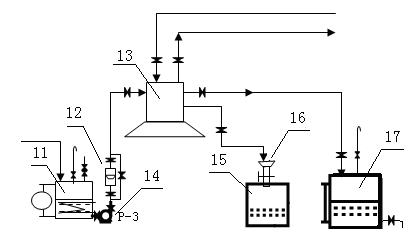

[0024] Embodiment 1, according to the continuous rectification of the present invention and the continuous drum crystallization integration method for extracting high-purity levamisole hydrochloride from levamisole hydrochloride aqueous solution, its process flow refers to figure 1 , figure 2 .

[0025] Described method comprises the following steps:

[0026] (1). Adopting the continuous feeding mode in the middle section of the tower, the raw material levamisole hydrochloride aqueous solution is squeezed into the tower still of the rectifying tower 4, and heating is started when the liquid level of the tower reaches 1 / 3; The plate number of distillation column is 5, and raw material levamisole hydrochloride aqueous solution feeds in the 3rd plate of continuous rectification column;

[0027] (2). When the temperature of the tower top and the kettle starts to stabilize and the rectification tower device reaches total reflux, the temperature of the tower top is 99-102°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com