Preparation method of silicon dioxide (SiO2) ultrasonic imaging radiography material

A technology of ultrasonic imaging and silicon dioxide, which is applied in the direction of echo/ultrasonic imaging agents, etc., to achieve the effects of pollution-free by-products, good biocompatibility, and affordable prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Measure 0.25 mL of commercial polystyrene microspheres (1 μm particle size) (5%, wt / v), add 7 mL of distilled water, 30 mL of isopropanol, 0.1 mL of tetraethyl orthosilicate (TEOS) (93 mg) , 0.01mL of 3-aminopropylsilane (9.5mg) and 0.2mL (mass concentration of 25% to 28%) ammonia water to adjust the pH value to 8 to 10, stir at room temperature for 3 hours, centrifuge, and wash to obtain the amino group on the surface. SiO 2 Microspheres.

[0033] Take 50mg of the above-mentioned SiO with amino groups on the surface 2 Microspheres, dispersed in 30mL tetrahydrofuran solution, extracted at 25°C for 8-10 hours, removed the hard template of polystyrene microspheres, and obtained SiO with amino groups on the surface 2 hollow microspheres.

[0034] According to the amino density test, the amino density is 8.65*10 -4 mol / g.

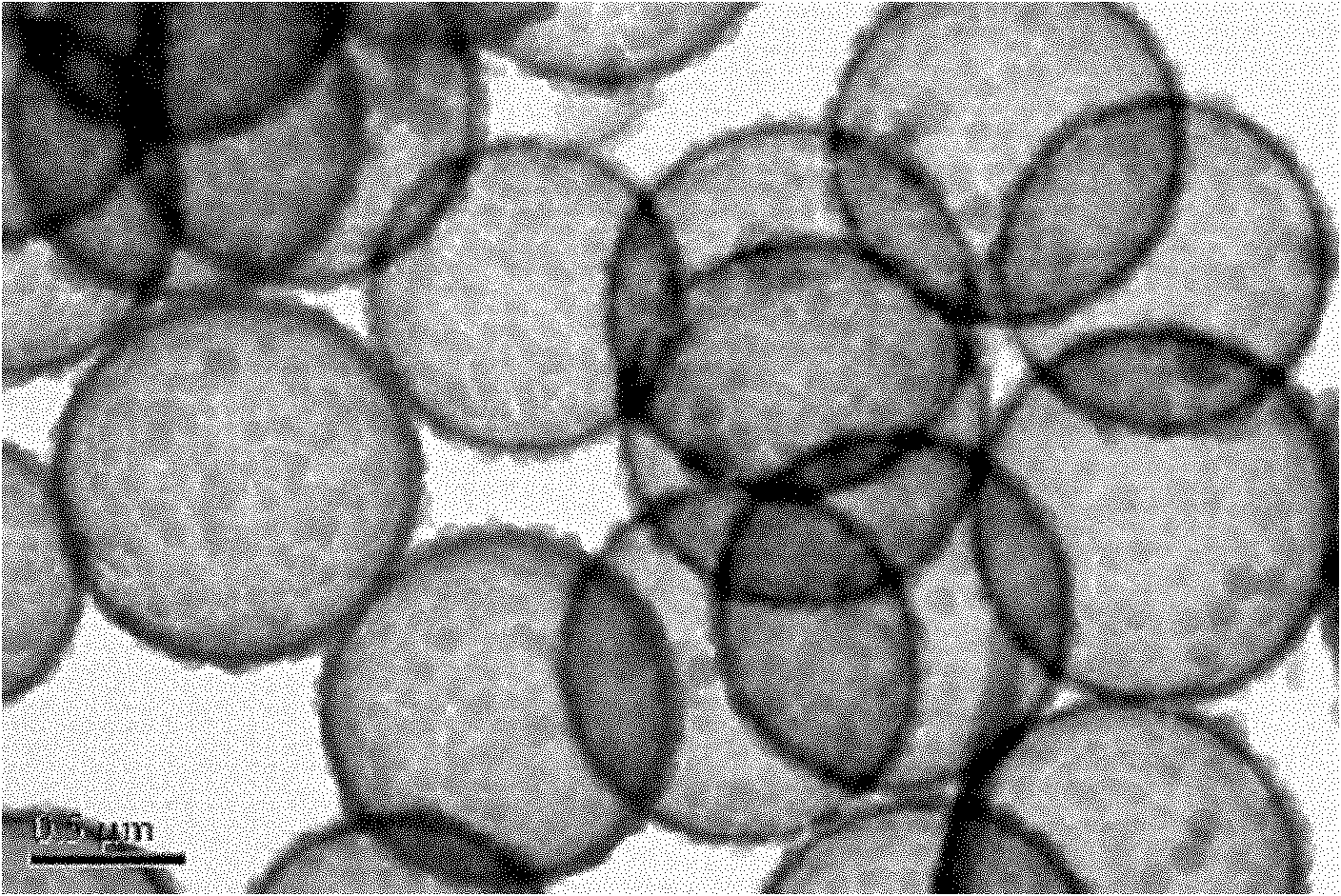

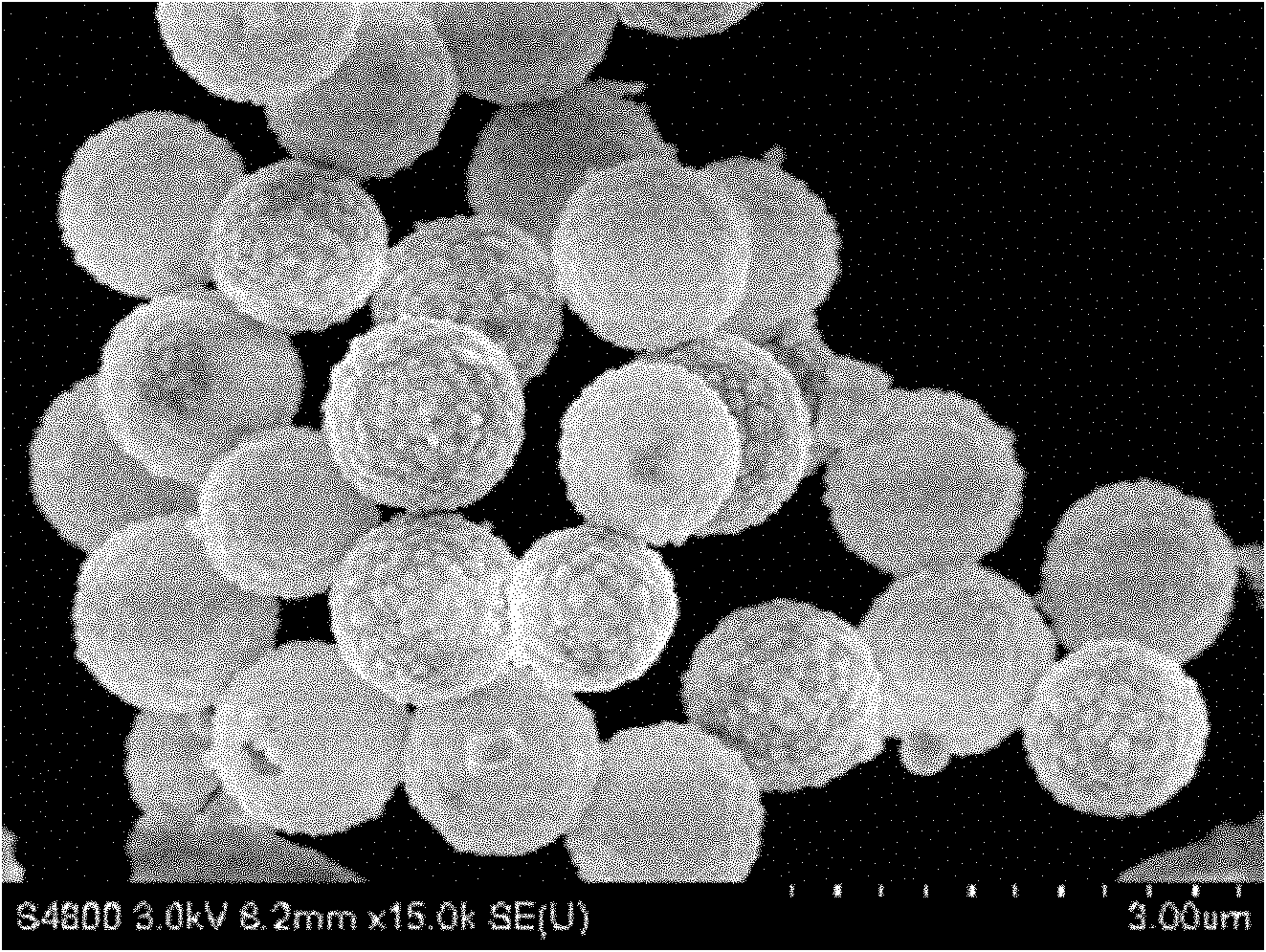

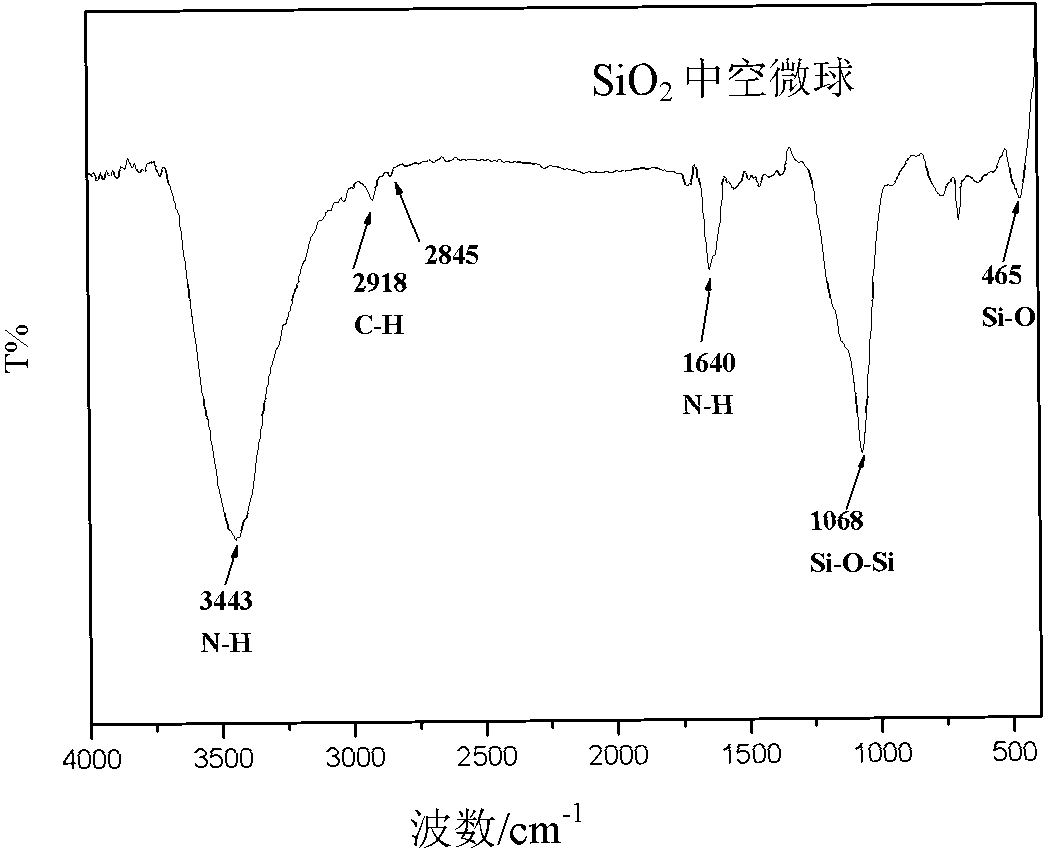

[0035] The transmission electron microscope picture is as figure 1 ; Field emission scanning electron microscope picture as figure 2 ; Infrared ...

Embodiment 2

[0037] The consumption of tetraethyl orthosilicate (TEOS) is 0.2ml (186mg), all the other are with embodiment 1. Infrared spectroscopy, transmission electron microscopy and field emission scanning electron microscopy detected that the prepared microspheres were SiO with amino groups on the surface. 2 hollow microspheres. According to the amino density test, the amino density is 4.85*10 -4 mol / g.

Embodiment 3

[0039] Take 6mg (3.46*10 -5 mol) PEG2000, dissolved in 20 mL of dimethyl sulfoxide (DMSO), added EDC (5 mg) and NHS (10 mg) according to the molar ratio of PEG: EDC: NHS = 1: 1: 2.5, stirred for 1 to 3 h, and used to activate the carboxyl group.

[0040] Add the SiO with amino group on the surface synthesized by 40mg embodiment 1 2 Hollow microspheres (the molar ratio of surface amino groups to PEG carboxyl groups is 1:1), slowly stirred at room temperature for 6-10 hours, washed, centrifuged, and freeze-dried to obtain very good biocompatibility, surface modified with PEG Alcoholic hollow SiO 2 microspheres for use in ultrasound imaging. The particle size is uniform, the average particle size is 960nm, and the thickness of the shell layer is suitable, which is 30-50nm.

[0041] field emission scanning electron microscope Figure 4 , it can be seen that there is almost no obvious change in its morphology after modification.

[0042] Infrared spectrum picture as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com