Nano carbon-covered alumina support-based preparation process of dehydrogenation catalyst

A technology of alumina carrier and preparation process, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic chemistry, etc., and can solve problems such as pollution, catalytic performance decline, alumina particle clogging, etc. , to achieve the effects of simplifying the preparation process, improving performance, and being easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

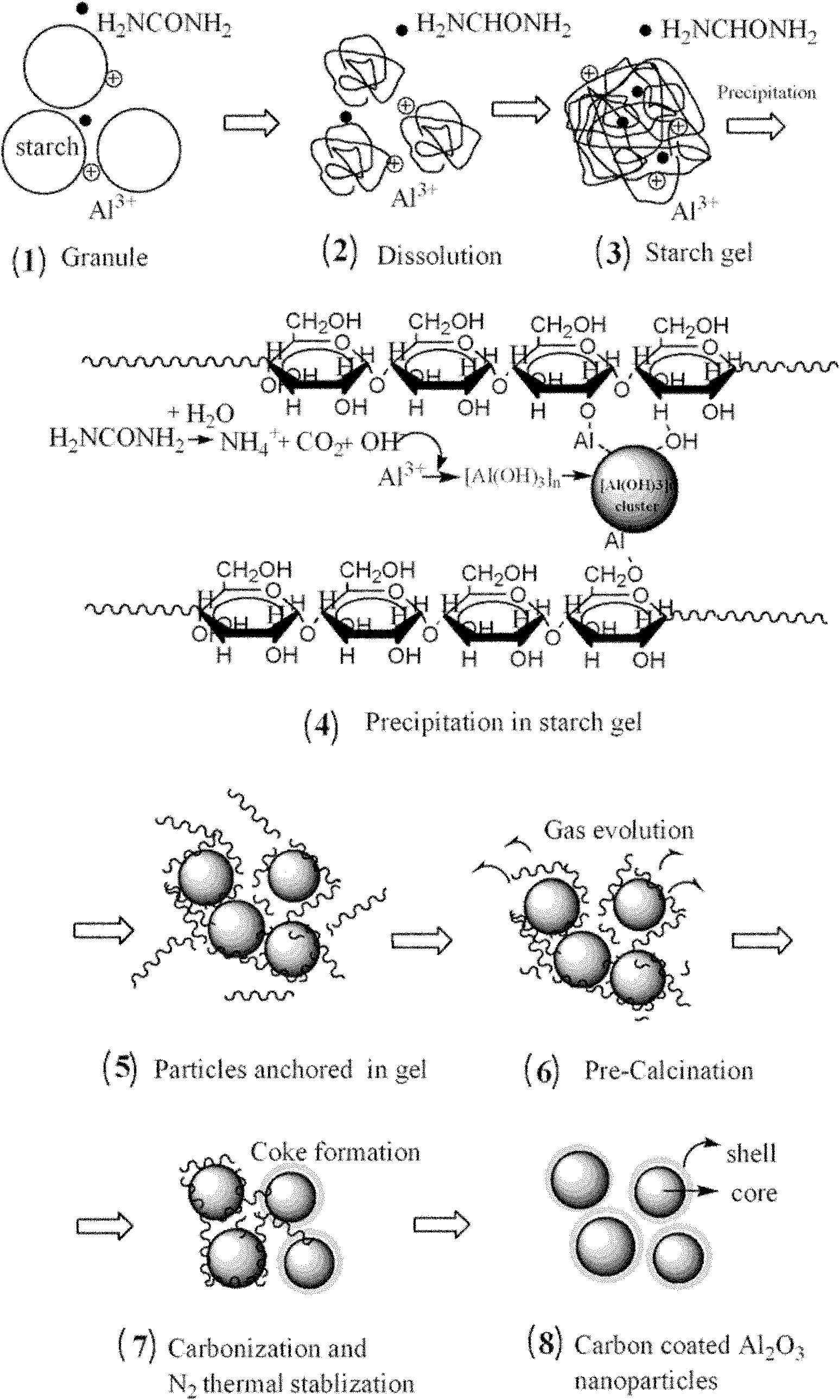

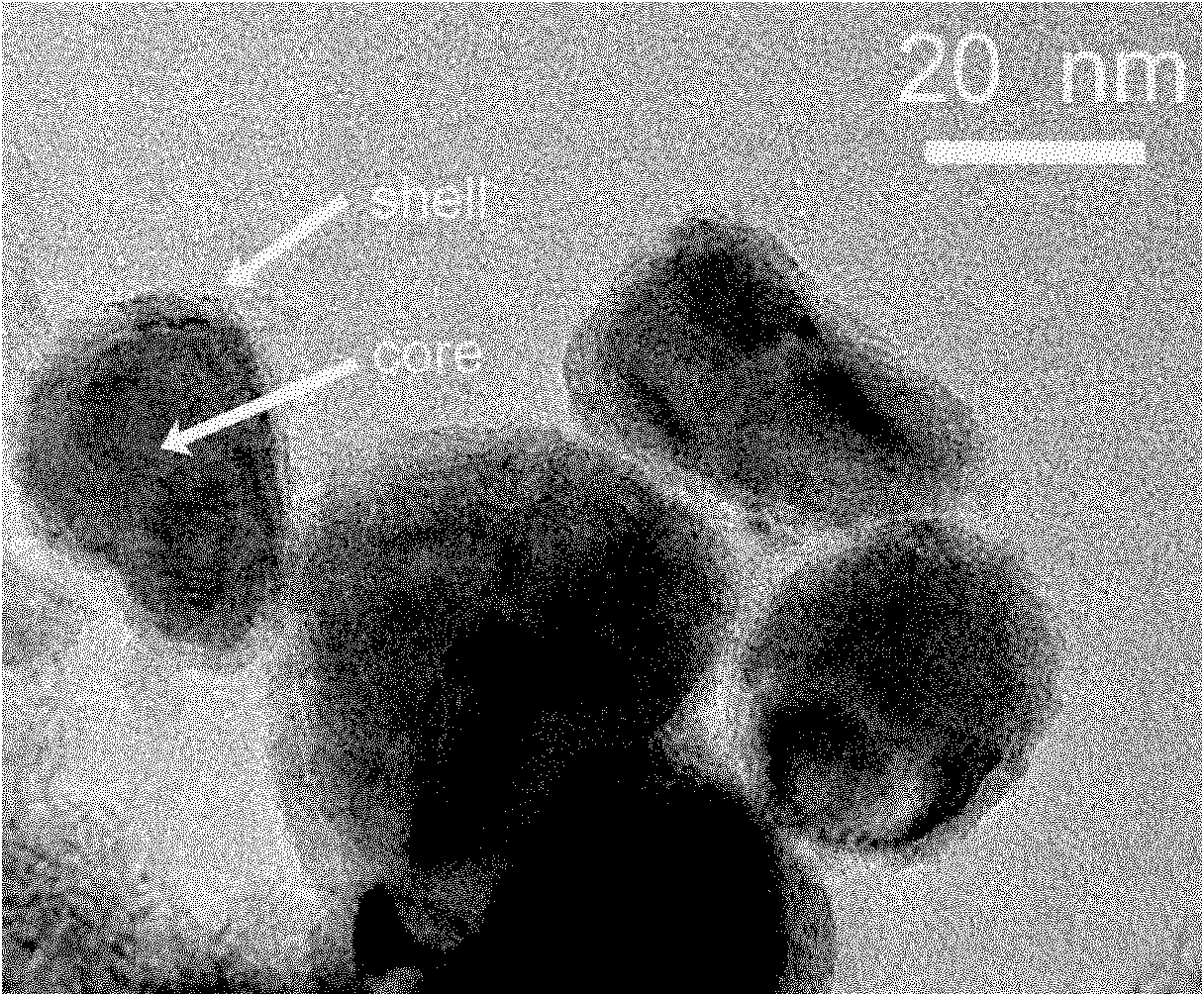

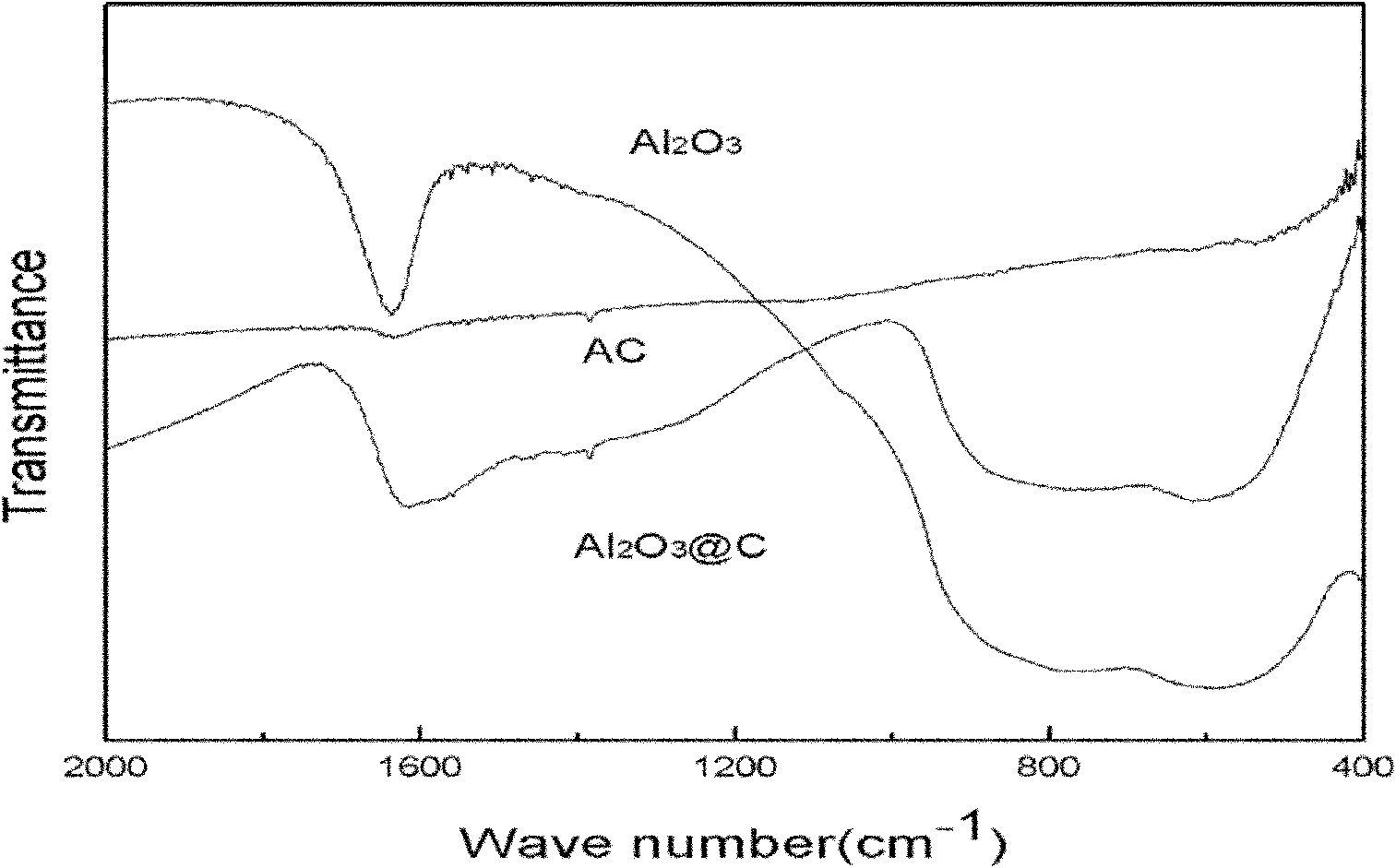

[0045] (1) Preparation of nano carbon-coated carrier

[0046] 14.2g aluminum chloride AlCl 3 .6H 2 O (g), 3.6g of soluble starch, and 5.2g of urea were dissolved in 30ml of deionized water, heated to 40°C and fully stirred to form a uniform mixed solution. Heat the above mixed solution to 85°C to gelatinize the starch molecules to form starch gel, and adjust the pH to 7. The above-mentioned gel was taken out, and the temperature was rapidly increased to 98° C., so that the urea was hydrolyzed and reacted with the inorganic aluminum salt to form a precipitate, and the time was 3 hours. After the above gel was taken and solidified, it was placed in a muffle furnace and heated to 350° C. for 2 hours in an air atmosphere for calcination to obtain a pre-calcined product. Transfer to a nitrogen atmosphere and heat up to 650°C for calcination for 4 hours to obtain nano-carbon-coated γ-Al 2 o 3 , denoted as nanoCCA-1.

[0047] (2) Active component loading process

[0048] 0.636...

Embodiment 2

[0053] (1) Preparation of nano carbon-coated carrier

[0054] 14.2g aluminum chloride AlCl 3 .6H 2 O (g), 1.8g of soluble starch, and 4.5g of urea were dissolved in 30ml of deionized water, heated to 60°C and fully stirred to form a uniform mixed solution. Heat the above mixed solution to 85°C to gelatinize the starch molecules to form starch gel, and adjust the pH to 7. The above-mentioned gel was taken out, and the temperature was rapidly increased to 95° C., so that urea was hydrolyzed and reacted with the inorganic aluminum salt to form a precipitate, and the time was 8 hours. After the above-mentioned gel was taken and solidified, it was placed in a muffle furnace and heated to 300°C in an air atmosphere for calcination for 5 hours to obtain a pre-calcined product. Transfer to a nitrogen atmosphere and heat up to 700°C for calcination for 5 hours to obtain nano-carbon-coated γ-Al 2 o 3 , denoted as nanoCCA-2.

[0055] (2) Active component loading process

[0056] 0...

Embodiment 3

[0060] (1) Preparation of nano carbon-coated carrier

[0061] 18.8g aluminum nitrate Al(NO 3 ) 3 .9H 2 O. Dissolve 3.0g of soluble starch and 4.5g of urea in 50ml of deionized water, heat to 50°C and stir thoroughly to form a uniform mixed solution. Heat the above mixed solution to 90°C to gelatinize the starch molecules to form starch gel, and adjust the pH to 8. The above-mentioned gel was taken out, and the temperature was rapidly increased to 95° C., so that the urea was hydrolyzed and reacted with the inorganic aluminum salt to form a precipitate, and the time was 12 hours. After the above gel was taken and solidified, it was placed in a muffle furnace and heated to 400° C. for 2 hours in an air atmosphere for calcination to obtain a pre-calcined product. Transfer to a nitrogen atmosphere and heat up to 700°C for calcination for 3 hours to obtain nano-carbon-coated γ-Al 2 o 3 , denoted as nanoCCA-3.

[0062] (2) Active component loading process

[0063] 1.21g nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com