Method for reclaiming and treating electronic waste

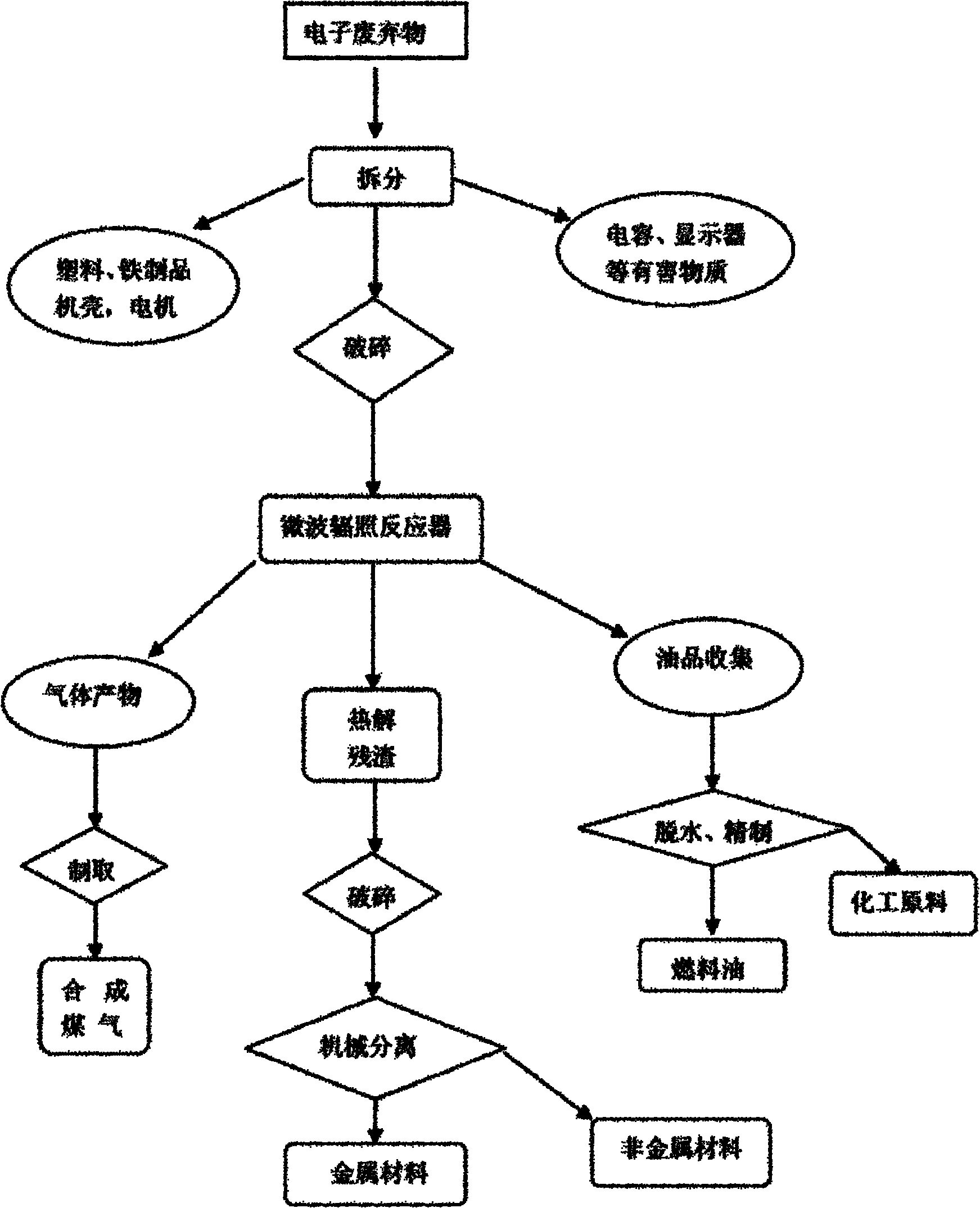

A technology for electronic waste and recycling, which is applied in the direction of electronic waste recycling, solid waste removal, recycling technology, etc., to achieve the effects of improving energy utilization, direct and efficient use of microwave energy, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

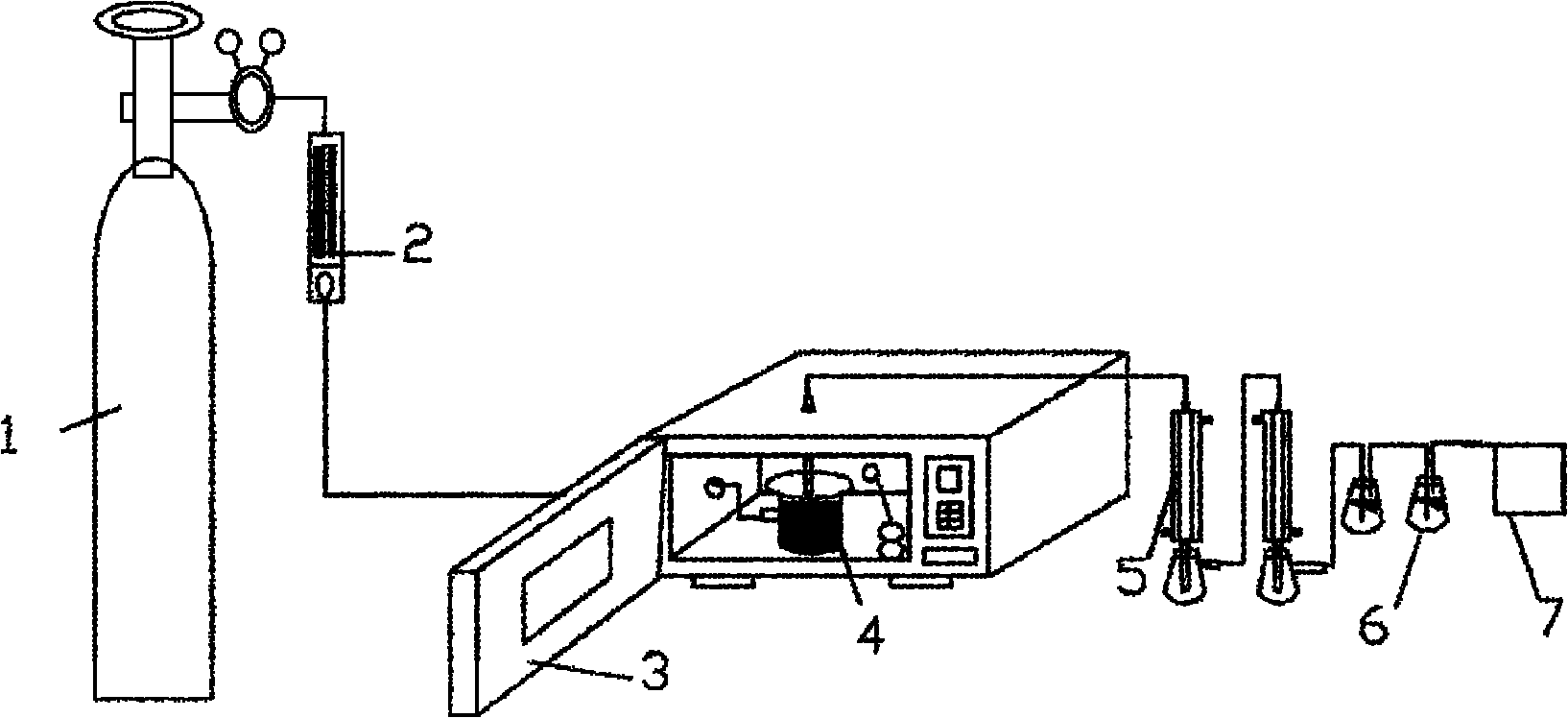

Embodiment 1

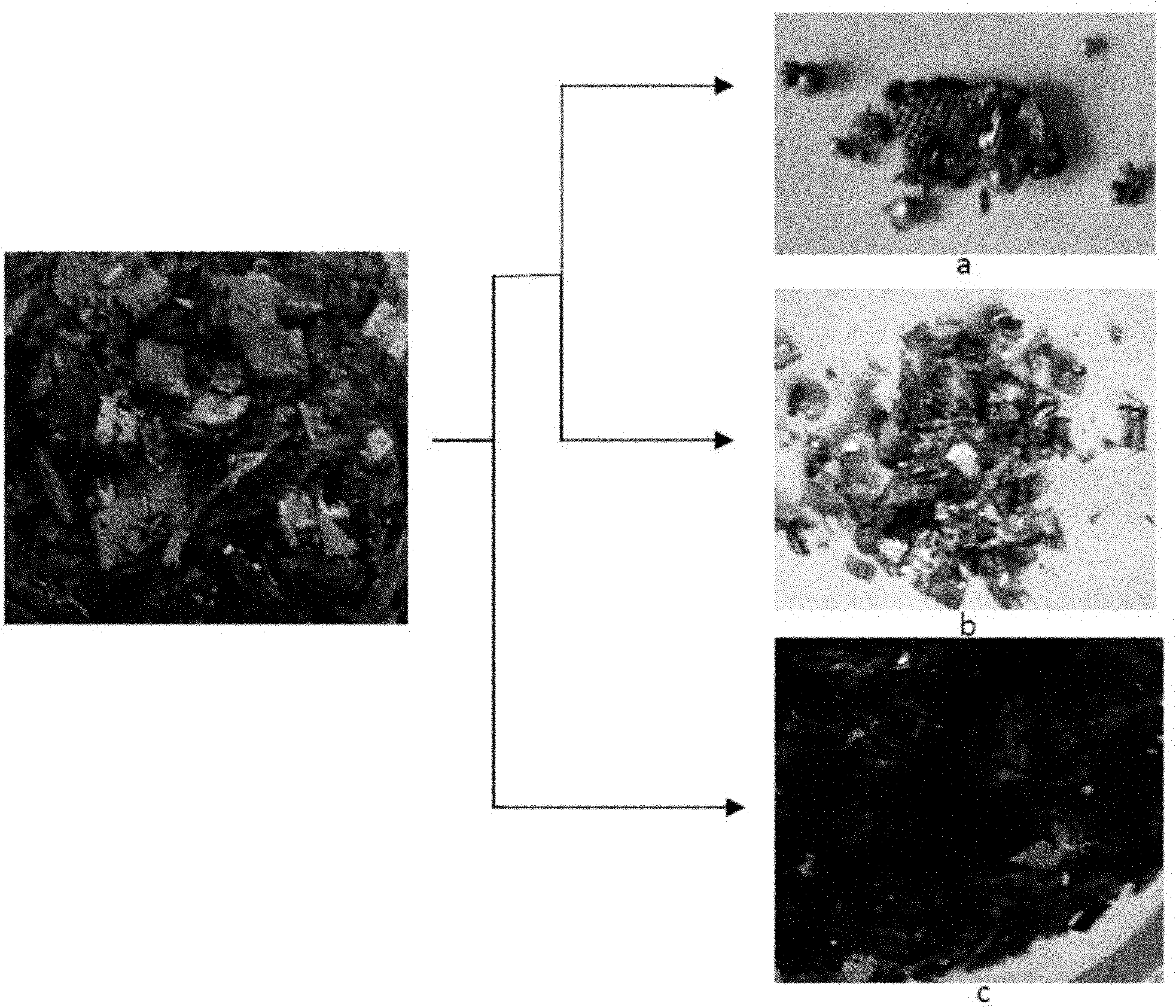

[0023] The waste computer main board is broken to less than 3cm×3cm and placed in the quartz reaction container 4 in the center of the microwave heating furnace 3, and sealed by a tetrafluoroethylene flange. Connected to each other, pass nitrogen for 30 minutes to make the air in the reactor as clean as possible, set the microwave power to 500W-700W, and the irradiation time to be 10-30min, so that the electronic waste undergoes thermal decomposition reaction, and the volatile matter is condensed by the condensing device 5 and enter The scrubber 6 equipped with NaOH solution is finally collected by the gas collection bag 7 to obtain gas, liquid and solid products respectively, and their yields are shown in Table 1. The composition of the analyzed gas is shown in Table 2, the composition of the oil product after treatment is shown in Table 3, the composition of the solid product is shown in Table 4, and the form is as follows image 3 shown.

[0024] Table 1 The yield of micro...

Embodiment 2

[0033] The solid product obtained in Example 1 was crushed with a high-speed rotating crushing device, the blade speed was 20000r / min, the glass fiber-reinforced matrix material was crushed, and the glass fiber cloth was crushed into fibers. Ensure that the conversion rate of glass fiber cloth broken into glass fiber reaches more than 95%.

[0034] The separation of metal and non-metal adopts the aforementioned cyclone flotation separation process. The metal recovery rate is above 98%, and the metal component content in the recovered metal mixture is over 91%, while the glass fiber recovery rate is high, the purity is good, and the fiber characteristics are good. The main composition of the recovered metal mixture is shown in Table 5.

[0035] Table 5 Main composition of recovered metal mixture

[0036] Cu

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com