Preparation method of nickel-cobalt hydroxide with controllable appearance

A nickel-cobalt hydroxide and hydroxide technology, which is applied in the field of preparation of nickel-cobalt hydroxide, can solve the problems of long period, single shape of nickel-cobalt hydroxide, uniform particle size and difficulty in shape control. , to achieve the effect of short process, simple reaction process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

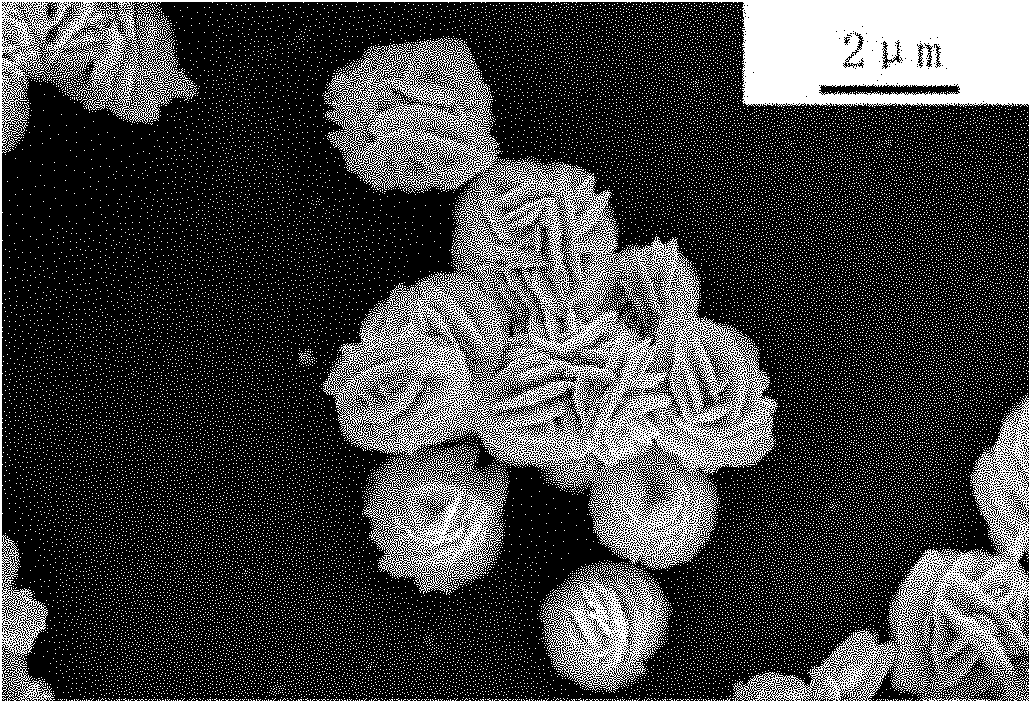

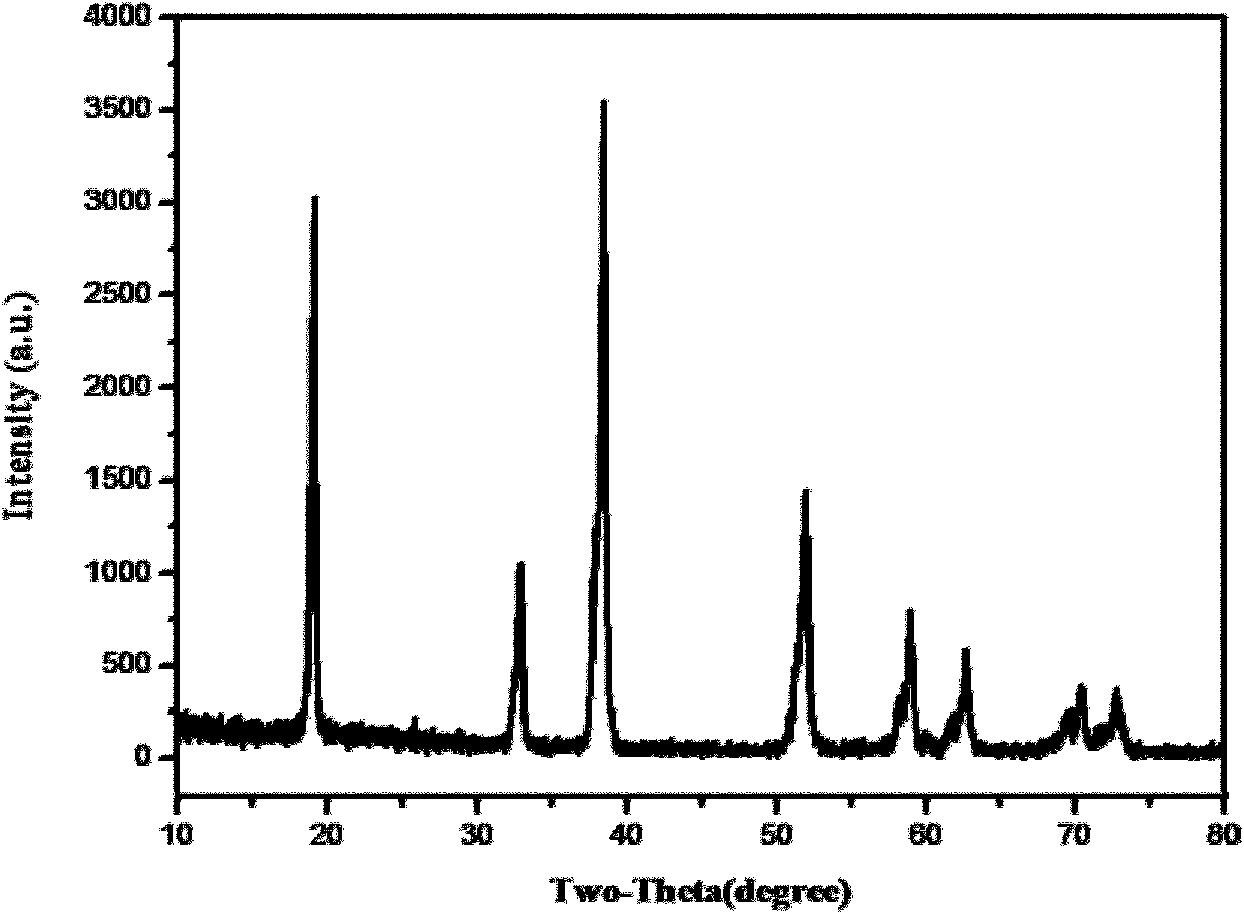

[0024] Prepare 10 ml of a mixed solution of nickel nitrate and cobalt nitrate with a concentration of 0.75 mol / L at room temperature, wherein the molar ratio of nickel ions to cobalt ions is 2:1, add 0.024 mol of ethylenediamine under stirring conditions, continue stirring for 1 h, and then Add 48ml of sodium hydroxide solution with a concentration of 7mol / L, stop stirring after 1h, then control the temperature at 100°C for 1h, filter and wash, then dry at 40°C for 12h to obtain the final product nickel-cobalt hydroxide. Scanned photographs and X-ray diffraction patterns such as figure 1 with figure 2 shown. The structure of the obtained nickel-cobalt hydroxide is a spherical structure, and the basic structural unit is a double-wheel structure. The diameter of the wheels on both sides is 1.5 μm, the thickness is 70 nm, and the length of the middle axis is 50 nm.

Embodiment example 2

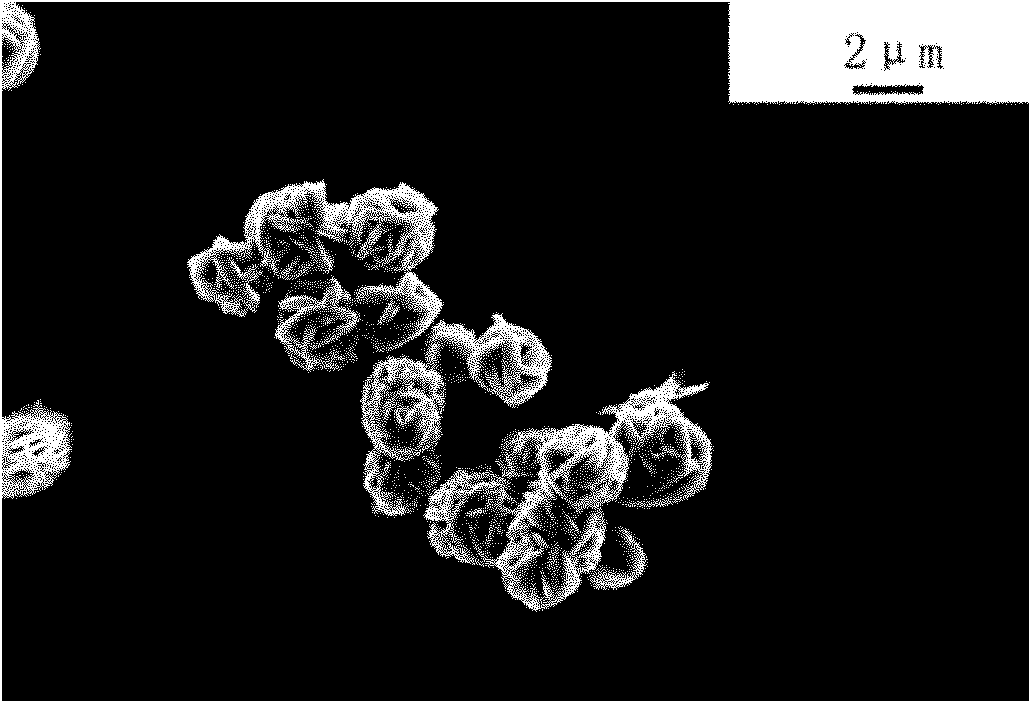

[0026] Prepare 10ml concentration of 0.75mol / L nickel nitrate and cobalt nitrate mixed solution at normal temperature, wherein the molar ratio of nickel ion and cobalt ion is 3:1, add 0.012mol triethylenetetramine under stirring condition, continue to stir for 1h, Then add 48ml of sodium hydroxide solution with a concentration of 8mol / L, stop stirring after 1.5h, then control the temperature at 90°C for 1.5h, filter and wash, then dry at 40°C for 12h to obtain the final product nickel-cobalt hydroxide , the scanned photo of the product is as image 3 As shown; the obtained nickel-cobalt hydroxide structure is a spherical structure, and the basic structural unit is a hexagonal disk, the thickness of the hexagonal disk is 100nm, and the side length is 600nm.

Embodiment example 3

[0028] Prepare 10 ml of a mixed solution of 0.8 mol / L nickel nitrate and cobalt nitrate at room temperature, wherein the molar ratio of nickel ions to cobalt ions is 1:3, add 0.012 mol of triethylenetetramine under stirring conditions, and continue stirring for 1 h. Then add 48ml of sodium hydroxide solution with a concentration of 7mol / L, stop stirring after 1.8h, then control the temperature at 110°C for 2h, filter and wash, then dry at 40°C for 12h to obtain the final product nickel-cobalt hydroxide, The scanned photo of the product is as Figure 4 shown. The obtained nickel-cobalt hydroxide structure is a three-dimensional sisal structure, and the basic structural unit is a smooth rod-like structure, wherein the length of the rod is 1.5 μm and the diameter is 400 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com