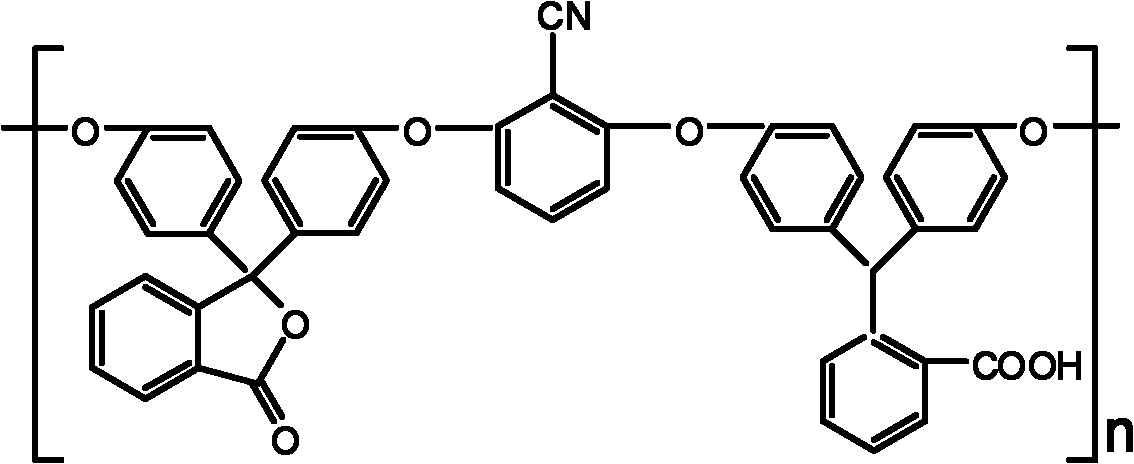

Fluorescent poly arylene ether nitrile multipolymer and preparation method thereof

A polyarylether nitrile and copolymer technology, applied in the field of fluorescent polyarylether nitrile copolymer and its preparation, to achieve the effects of easy control of the production process, easy availability of raw materials, and strong fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

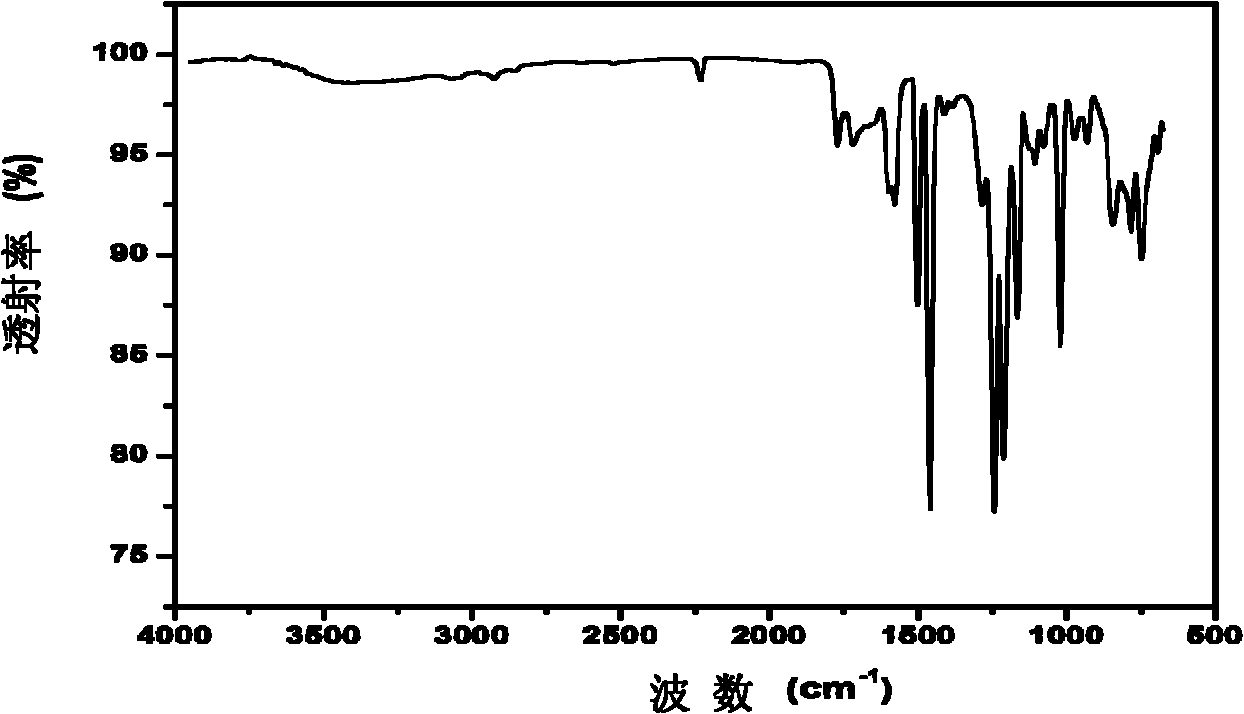

[0026] The molar ratio is 2,6-dichlorobenzonitrile: phenolphthalein: phenolphthalein: potassium carbonate: N-methylpyrrolidone: toluene = 1: 0.75: 0.25: 1.1: 6: 1.3 Ratio by weighing raw materials, the raw materials Put it into a reaction kettle with a water separator, agitator and a heater, start stirring, raise the temperature to 140°C for dehydration reaction for 3 hours, steam the toluene through the water separator, raise the temperature to 200°C, and react until climbing rods appear When the phenomenon occurs, stop the reaction. The reactant was poured into methanol for the first precipitation, and the first precipitate was pulverized, acidified with dilute hydrochloric acid, washed with boiling water, filtered, and dried to obtain a crude product. Then the crude product was dissolved and filtered with dimethylformamide, and the filtrate was precipitated with hot water for the second time, and the precipitate was filtered and dried for the second time to obtain a fluores...

Embodiment 2

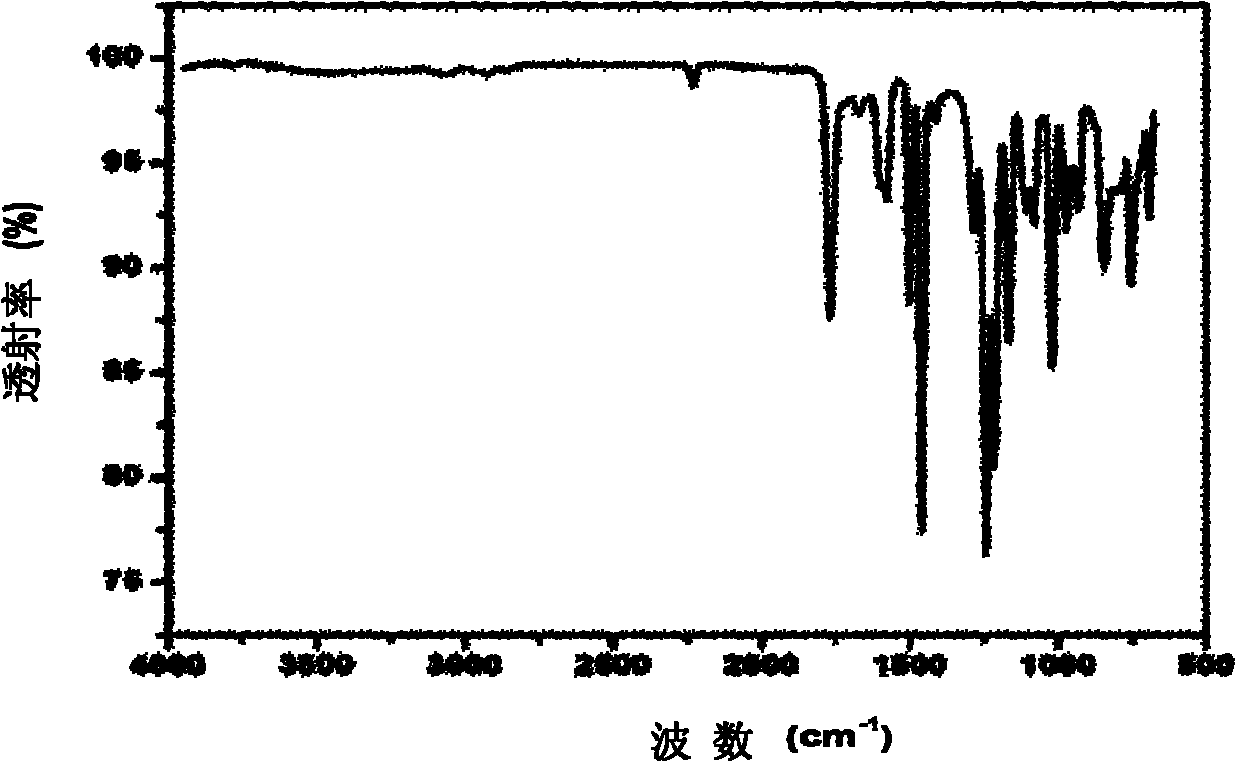

[0030] The molar ratio is 2,6-dichlorobenzonitrile: phenolphthalein: phenolphthalein: potassium carbonate: N-methylpyrrolidone: toluene = 1: 0.5: 0.5: 1.2: 7: 1.4 Ratio by weighing raw materials, the raw materials Put it into a reaction kettle with water separator, agitator and heater, start stirring, raise the temperature to 150°C for dehydration reaction for 2.5 hours, steam the toluene through the water separator, raise the temperature to 200°C, and react until climbing rods appear When the phenomenon occurs, stop the reaction. The reactant was poured into water for the first precipitation, and the first precipitate was pulverized, acidified with dilute hydrochloric acid, washed with boiling water, filtered, and dried to obtain a crude product. Then the crude product is dissolved and filtered with dimethylformamide, and its filtrate is precipitated for the second time with methanol. After the second precipitate is filtered and dried, the fluorescent polyarylether nitrile co...

Embodiment 3

[0034] The molar ratio is 2,6-dichlorobenzonitrile: phenolphthalein: phenolphthalein: potassium carbonate: N-methylpyrrolidone: toluene = 1: 0.25: 0.75: 1.1: 8: 1.5 Ratio by weighing raw materials, the raw materials Put it into a reaction kettle with a water separator, agitator and a heater, start stirring, raise the temperature to 160°C for dehydration reaction for 2 hours, steam the toluene through the water separator, raise the temperature to 200°C, and react until climbing rods appear When the phenomenon occurs, stop the reaction. The reactant was poured into water for the first precipitation, and the first precipitate was pulverized, acidified with dilute hydrochloric acid, washed with boiling water, filtered, and dried to obtain a crude product. Then the crude product is dissolved and filtered with dimethylformamide, and its filtrate is precipitated for the second time with methanol. After the second precipitate is filtered and dried, the fluorescent polyarylether nitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com