Medicinal gullet scaffold fiber and preparation method thereof

A technology of fiber and esophagus, applied in the field of medical esophageal stent fiber and its manufacture, medical esophageal stent fiber and its preparation, can solve the problems of poor toughness and biodegradability, unseen problems, etc., and achieve good biodegradability, The effect of high mechanical support strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of medical esophageal stent fiber of the present invention comprises the steps:

[0027] PPDO slices→drying→screw extrusion and ejection→cooling liquid cooling→stretching→winding→PPDO fiber

[0028] The specific process is as follows:

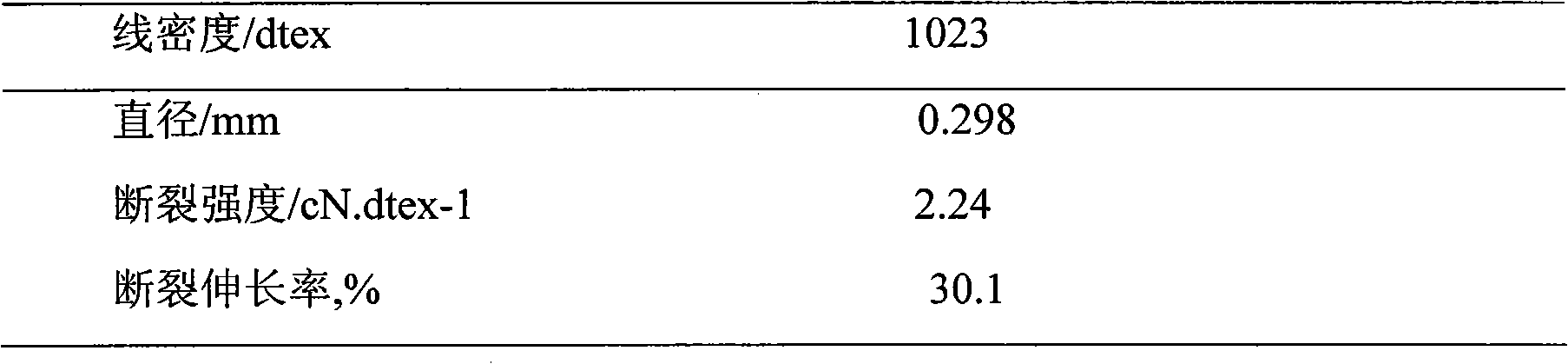

[0029] The polydioxanone chips are first dried at 70°C and have a moisture content of 29ppm, and are melted and extruded into the spinning box by twin-screws for spinning, and the spinning temperature is 135°C; then extruded through the spinneret The polydioxanone monofilament enters the cooling tank for cooling and solidification molding, the cooling liquid is 1,2-propylene glycol and absolute ethanol, the mass ratio of the two is 3:1, and the temperature is 35 °C; then use absolute ethanol The cooled and solidified polydioxanone fiber is cleaned, and the temperature is controlled at 30°C; then the obtained fiber is stretched on a hot plate, the stretching temperature is 60°C, and the one-time stretching ra...

Embodiment 2

[0033] This fiber preparation method comprises the steps:

[0034] PPDO slicing→drying→screw extrusion and spraying→cooling liquid cooling→stretching→winding→PPDO fiber The specific process is as follows:

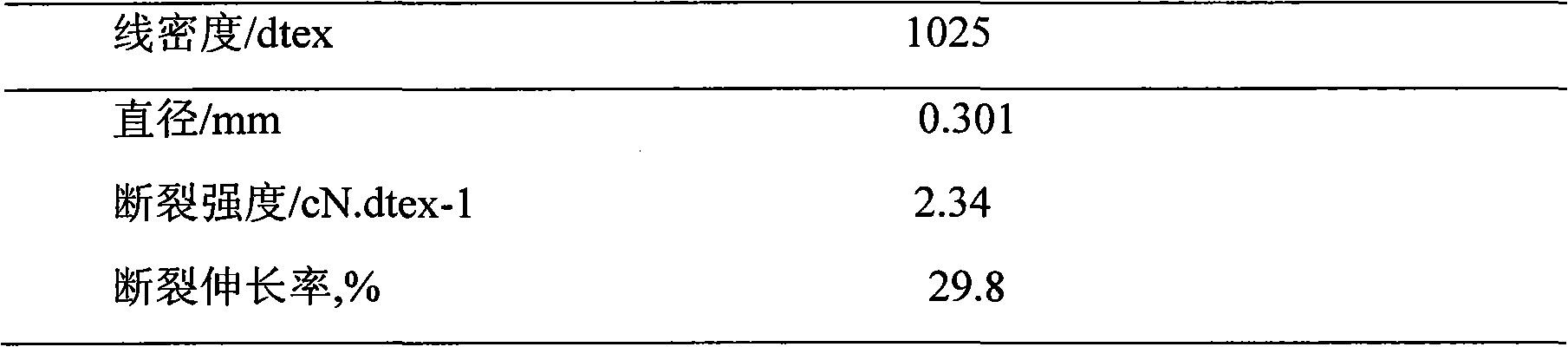

[0035] The polydioxanone chips are first dried at 75°C, and the moisture content is 26ppm. They are melted and extruded into the spinning box for spinning by twin-screw, and the spinning temperature is 145°C; then extruded through the spinneret The polydioxanone monofilament enters the cooling tank for cooling and solidification molding, the cooling liquid is 1,2-propylene glycol and absolute ethanol, the mass ratio of the two is 3.5:1, and the temperature is 38 °C; then use absolute ethanol The cooled and solidified polydioxanone fiber is cleaned, and the temperature is controlled at 35°C; then the obtained fiber is stretched on a hot plate at a stretching temperature of 70°C, and the one-time stretching ratio is 5 times; Winding after shaping, the heat setting temperatur...

Embodiment 3

[0039] This fiber preparation method comprises the steps:

[0040] PPDO slicing→drying→screw extrusion and spraying→cooling liquid cooling→stretching→winding→PPDO fiber The specific process is as follows:

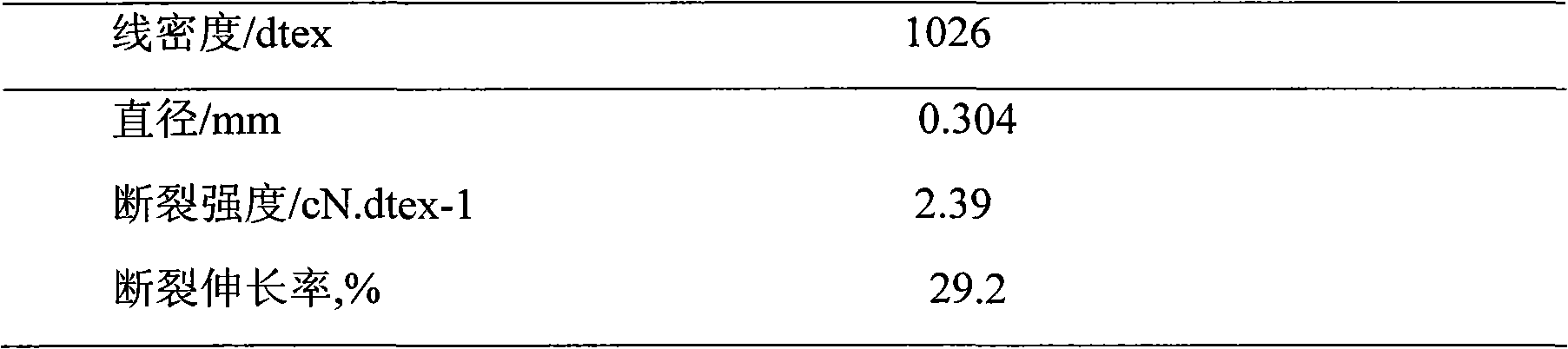

[0041] The polydioxanone chips are first dried at 80°C and have a moisture content of 27ppm. They are melted and extruded into the spinning box by twin-screws for spinning, and the spinning temperature is 155°C; then extruded through the spinneret The polydioxanone monofilament enters the cooling tank for cooling and solidification molding, the cooling liquid is 1,2-propylene glycol and absolute ethanol, the mass ratio of the two is 4:1, and the temperature is 40 °C; then use absolute ethanol The cooled and solidified polydioxanone fiber is cleaned, and the temperature is controlled at 38°C; then the obtained fiber is stretched on a hot plate, the stretching temperature is 75°C, and the one-time stretching ratio is 8 times; Winding after shaping, the heat setting temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com