Polyethylene artificial joint capable of improving biocompatibility and tribological property and preparation method thereof

A technology of biocompatibility and artificial joints, which is applied in the field of polyethylene artificial joints and its preparation, can solve the problems of polyethylene degradation and accelerated aging, and achieve the goal of reducing aseptic loosening, reducing tissue reactions and improving biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

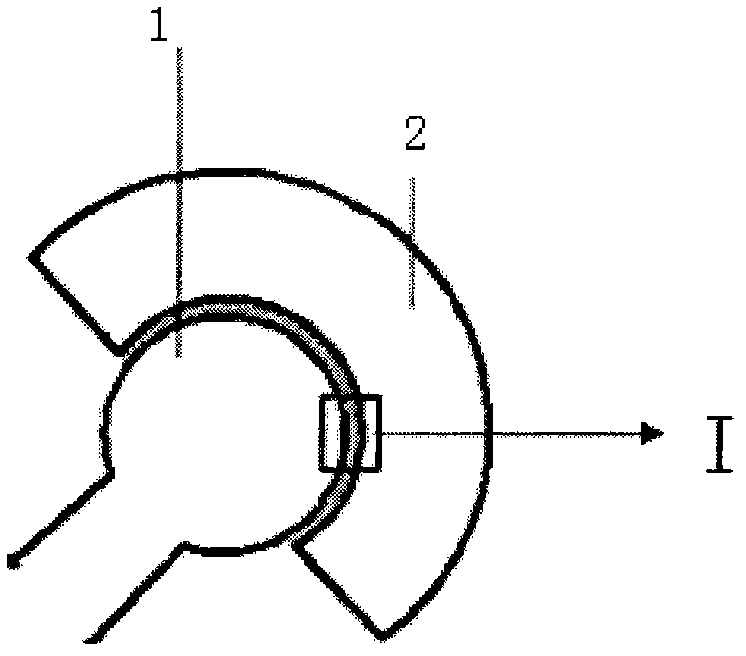

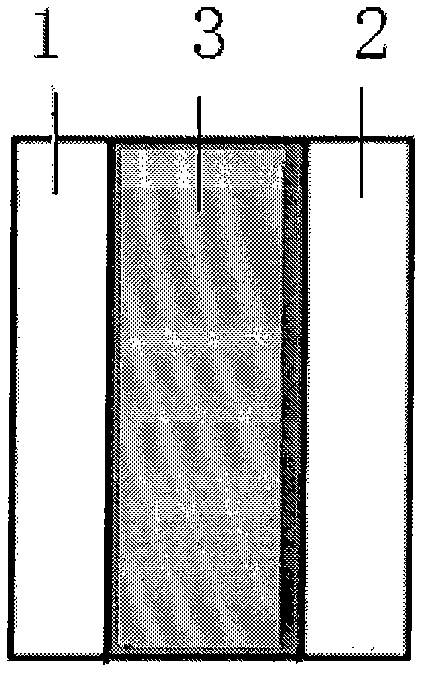

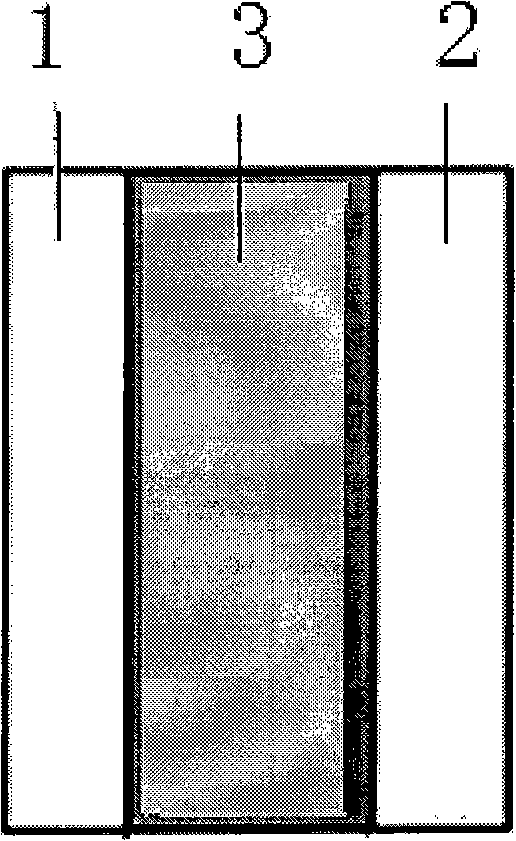

Image

Examples

Embodiment 1

[0017] Put a polyethylene sample with a molecular weight of 2 million into methanol and ultrasonically clean it for 30 minutes, wash it twice, and dry it; then soak it in an acetone solution with a concentration of 0.02g / ml benzophenone, take it out after 2 hours, The photosensitizer-precoated polyethylene was prepared by vacuum drying in the dark for 1 hour at room temperature to remove the solvent.

[0018] Immerse the polyethylene sample above in 0.5mol / L aqueous solution of 2-methylpropanoyloxyethylphosphorylcholine, blow in nitrogen gas and keep stirring, heat to 60°C, then keep the temperature constant, and irradiate with 500W ultraviolet light Irradiate for 15 minutes, wash with ethanol and deionized water at 50°C, and dry under vacuum for 24 hours.

Embodiment 2

[0020] Put a polyethylene sample with a molecular weight of 3 million into methanol and ultrasonically clean it for 30 minutes, wash it twice, and dry it; then soak it in an acetone solution with a concentration of 0.04g / ml benzophenone, take it out after 2 hours, The photosensitizer-precoated polyethylene was prepared by vacuum drying in the dark for 1 hour at room temperature to remove the solvent.

[0021] Immerse the polyethylene sample above in 0.5mol / L aqueous solution of 2-methylpropanoyloxyethylphosphorylcholine, blow in nitrogen gas and keep stirring, heat to 40°C and keep the temperature, and irradiate with 500W ultraviolet light Leave on for 20 minutes, wash with 50°C ethanol and deionized water, and dry under vacuum for 24 hours.

Embodiment 3

[0023] Put a polyethylene sample with a molecular weight of 5 million into methanol and ultrasonically clean it for 30 minutes, wash it twice, and dry it; then soak it in an acetone solution with a concentration of 0.02g / ml benzophenone, take it out after 2 hours, The photosensitizer-precoated polyethylene was prepared by vacuum drying in the dark for 1 hour at room temperature to remove the solvent.

[0024] Immerse the polyethylene sample above in 0.5mol / L aqueous solution of 2-methylpropyloxyethylphosphorylcholine, blow in nitrogen gas and keep stirring, heat to 30°C and keep the temperature, and irradiate with 500W ultraviolet light Leave on for 30 minutes, wash with ethanol and deionized water at 50°C, and dry under vacuum for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com