Method for preparing anti-adhesive membrane for tendon ligaments

An anti-adhesion film and tendon technology, applied in the field of medical materials, can solve problems such as uncontrollable absorption time, secondary damage to the body, unsatisfactory effect, etc., and achieve the effects of relieving pain, promoting repair, and preventing exogenous healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of tendon and ligament anti-adhesion film of the present invention comprises the following steps:

[0021] 1. Slurry Preparation

[0022] 1.1 Raw material thawing:

[0023] The collagen is taken out from the freezer, and the usage amount of the batch is calculated according to the water content, placed in a sterilized plate, and used after thawing at room temperature.

[0024] 1.2 Preparation calculation method

[0025] 600ml acid solution contains 3-5g dry collagen

[0026] 1. Preparation of 30.05M glacial acetic acid:

[0027] Take 2-6ml of glacial acetic acid to a 1000ml Erlenmeyer flask, add sterile water to 720ml, stir with a magnetic stirrer for 10 minutes, and measure the pH to be 2.5-5.0.

[0028] 1.4 Preparation of chondroitin sulfate sodium salt:

[0029] Add 0.2-0.6g chondroitin sulfate sodium salt to 120ml of 0.05M glacial acetic acid, stir with a magnetic stirrer for 20-50 minutes, set it to dissolve completely (no visible insolu...

experiment example

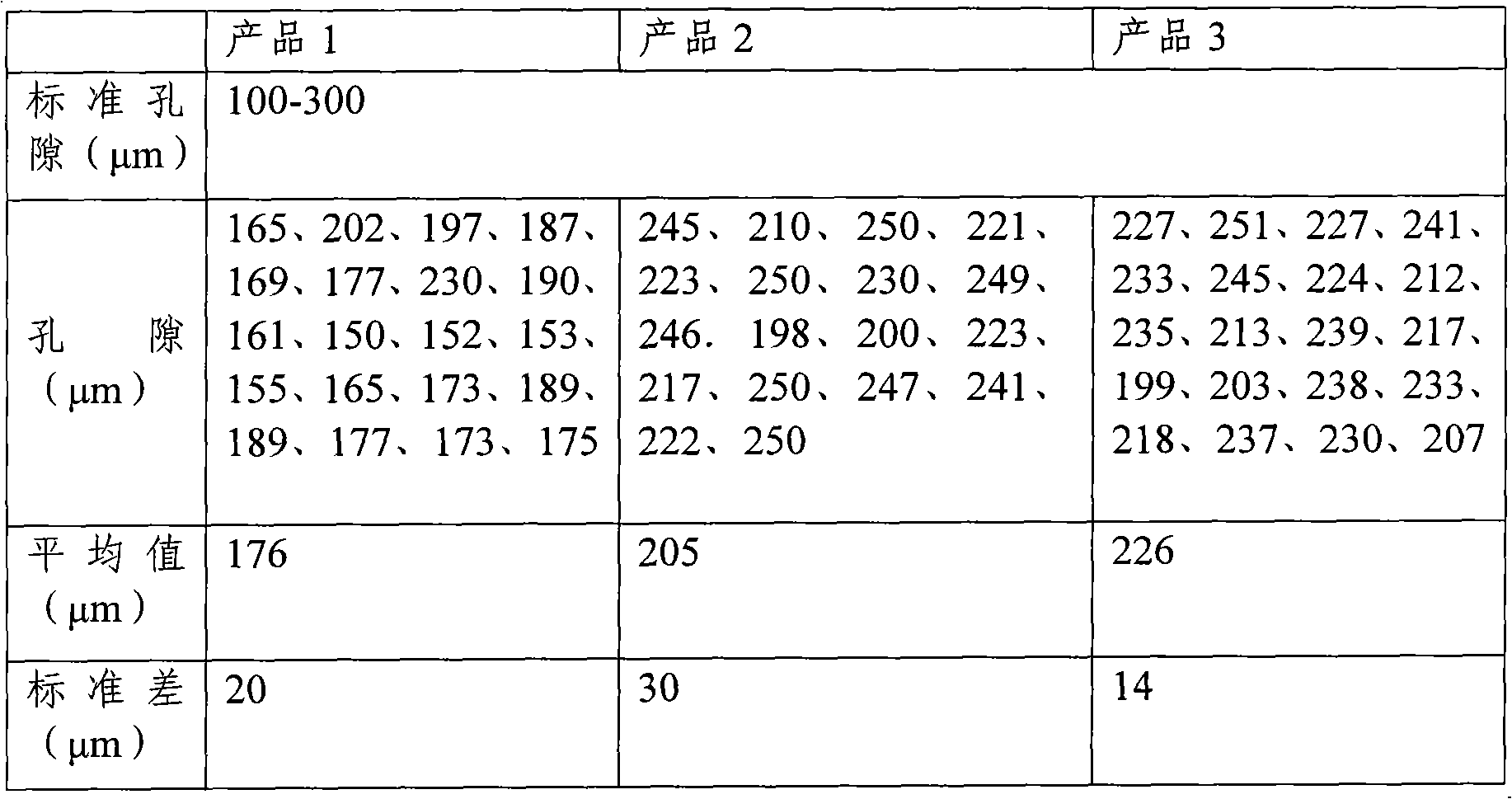

[0071] Adopt the method for embodiment 1 to prepare a plurality of products, adopt electron microscope to measure the pore size in its structure, the result is as shown in the table below:

[0072] It can be seen from the above test examples that the tendon and ligament anti-adhesion film prepared by the present invention has a specific three-dimensional pore structure, and the pore size is basically about 200-220 μm.

[0073] In the embodiment of the present invention, the type I collagen and chondroitin sulfate are mixed and stirred in a certain concentration of acid water to form a slurry, and then a degradable collagen sponge film with specific pores is made under a freeze-drying process, and then temperature cross-linked. Package. The product has the advantages of absorbability, antigen-free, and suture-free. It can effectively prevent or reduce the formation of adhesions and promote the repair of damaged tendons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com