Method for preparing copper-zinc-zirconium composite oxide catalyst

A composite oxide and catalyst technology, applied in the preparation of organic compounds, catalyst activation/preparation, preparation of hydroxyl compounds, etc., can solve the problems of difficult industrial production, low catalyst activity, cumbersome preparation process, etc. Good activity and stability, rich source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

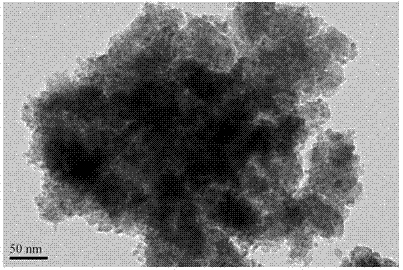

Image

Examples

Embodiment 1

[0036] (1) Weigh 0.1 g of konjac glucomannan and add it to 100 ml of deionized water, and stir to form an aqueous solution of konjac glucomannan with a mass concentration of 0.1%; weigh 2.718 g of Cu(NO 3 ) 2 ·3H 2 O, 3.346g of Zn(NO 3 ) 2 ·6H 2 O and 1.073g of Zr(NO 3 ) 4 ·5H 2 O is dissolved in 100 ml of deionized water to form a mixed solution with a molar percentage of copper of 45%, a molar percentage of zinc of 45%, and a molar percentage of zirconium of 10%; a sodium carbonate aqueous solution with a concentration of 0.2mol / L is prepared.

[0037] (2) Pour the mixed solution of copper, zinc and zirconium and the aqueous solution of sodium carbonate into two separatory funnels, and add them dropwise to the aqueous solution of konjac glucomannan at the same time, and adjust the dropping speed of the mixed aqueous solution of copper, zinc and zirconium to 0.8ml / min, the dropping speed of the sodium carbonate aqueous solution is 0.5ml / min, and the pH value is controlled to be a...

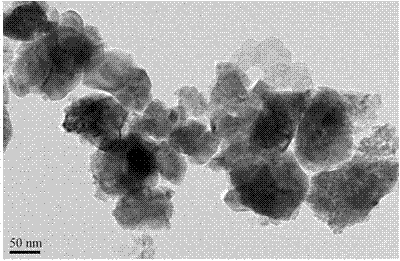

Embodiment 2

[0040] Same as Example 1, except that the mass concentration of the aqueous konjac glucomannan solution is 0.3%. Prepared CuO-ZnO-ZrO 2 Catalyst B. The particle size is uniform, and the scale is between 10-25nm. BET specific surface area is 80~90m 2 And Cu surface area 12~14m 2 .

Embodiment 3

[0042] Same as Example 1, except that the mass concentration of the aqueous konjac glucomannan solution is 0.5%. Prepared CuO-ZnO-ZrO 2 Catalyst C. The particle size is uniform, and the scale is between 5-20nm. BET specific surface is 90~100m 2 And Cu surface area 14~15m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com