Device for testing metallic film failure behaviors under the coupling of force, heat, power and magnetism multi-field

A metal thin film, magnetic coupling technology, applied in measurement devices, single semiconductor device testing, instruments, etc., can solve the problems of open-circuit failure, system catastrophic, errors, etc., and achieve the effect of reducing failure rate, easy to promote, and practical promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

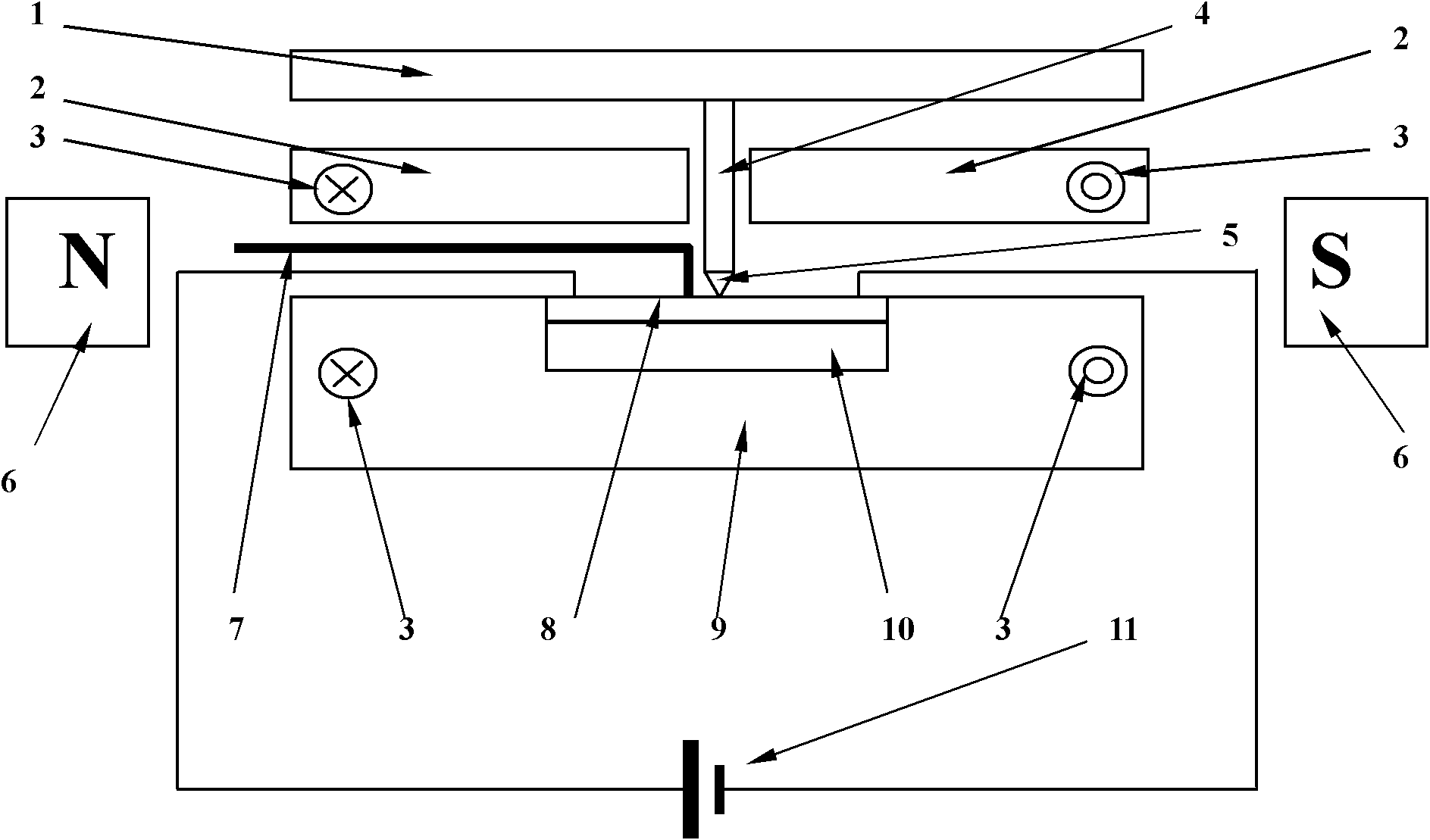

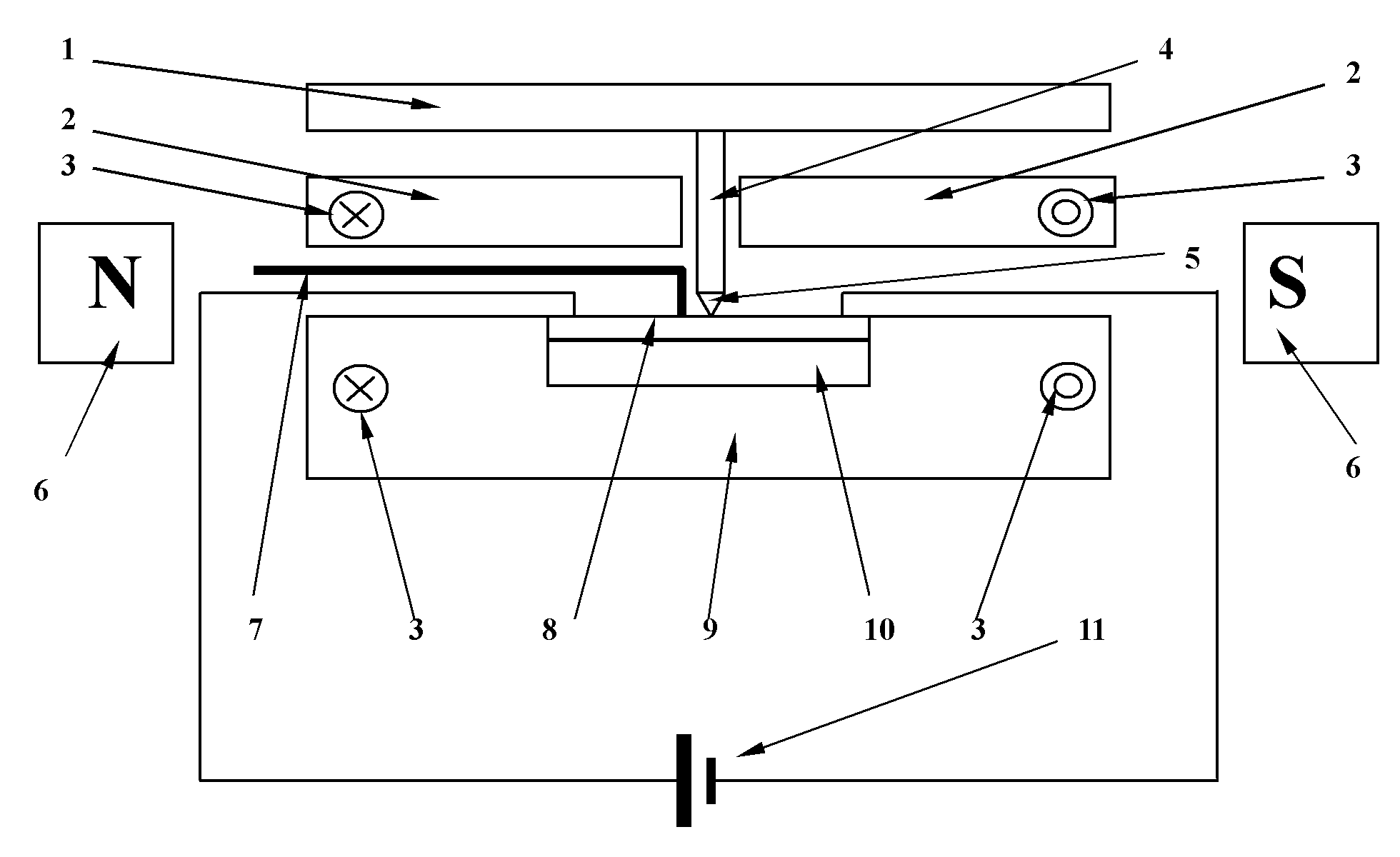

[0024] A metal Cu film with a line width of 2 microns was deposited on single crystal Si by photolithography and magnetron sputtering, and a TaN barrier layer was plated between the Cu film and Si to prevent Cu from diffusing to Si. Place the Cu film at 8 places in the device, turn on the heating platform 10, and control the constant direct current with a current intensity of 0.5A through a micro-nano digital ammeter. The magnetic pole 6 is placed on both sides of the heat insulation platform 9 perpendicular to the metal film, and applied in parallel. While applying a steady magnetic field, the film is heated to 100°C, protected by an argon atmosphere (to avoid oxidation) and cooled by circulating water. The magnetic induction intensity selected for the test is 0.5T. Using the fixed maximum load method, take P max = 100 μN, the load-displacement curve was obtained by a nanoindenter, and repeated 20 times. The load-displacement curve has good repeatability, indicating that th...

Embodiment 2

[0026] A metal Cu film with a line width of 2 microns was deposited on single crystal Si by photolithography and magnetron sputtering, and a TaN barrier layer was plated between the Cu film and Si to prevent Cu from diffusing to Si. Place the Cu film at 8 places in the device, turn on the heating platform 10, and control the constant direct current with a current intensity of 0.3A through a micro-nano digital ammeter. The magnetic pole 6 is placed on both sides of the heat insulation platform 9 perpendicular to the metal film, and applied in parallel. While applying a steady magnetic field, the film is heated to 100°C, protected by an argon atmosphere (to avoid oxidation) and cooled by circulating water. The magnetic induction intensity selected for the test is 0.3T. Using the fixed maximum load method, take P max = 150 μN, the load-displacement curve was obtained by a nanoindenter, and repeated 20 times. The load-displacement curves are very repeatable, indicating that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com