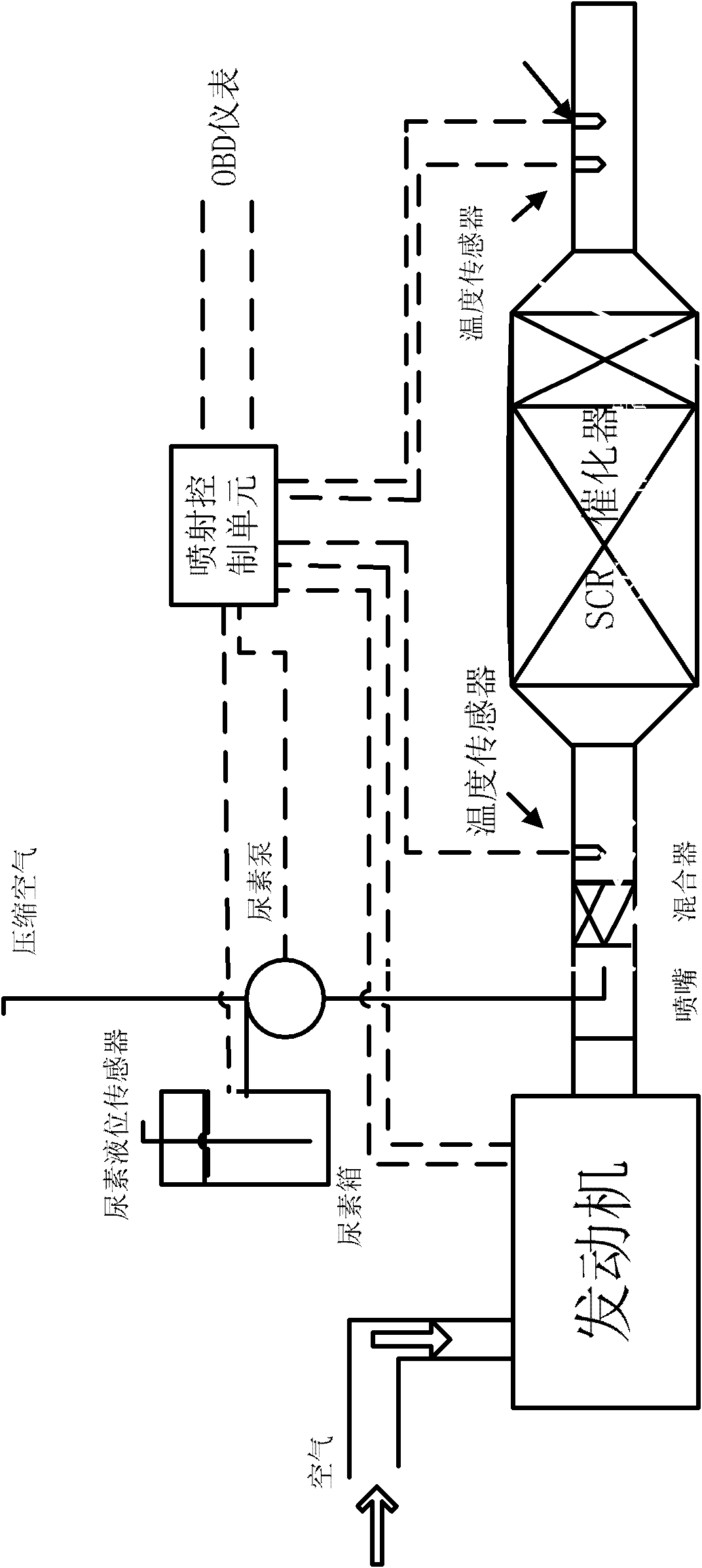

Mixing device for diesel engine urea SCR system

A technology of SCR system and mixing device, applied in mixers, mufflers, exhaust devices, etc., can solve the problems of ammonia leakage and low conversion efficiency, and achieve the effect of reducing crystallization, easy processing and installation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

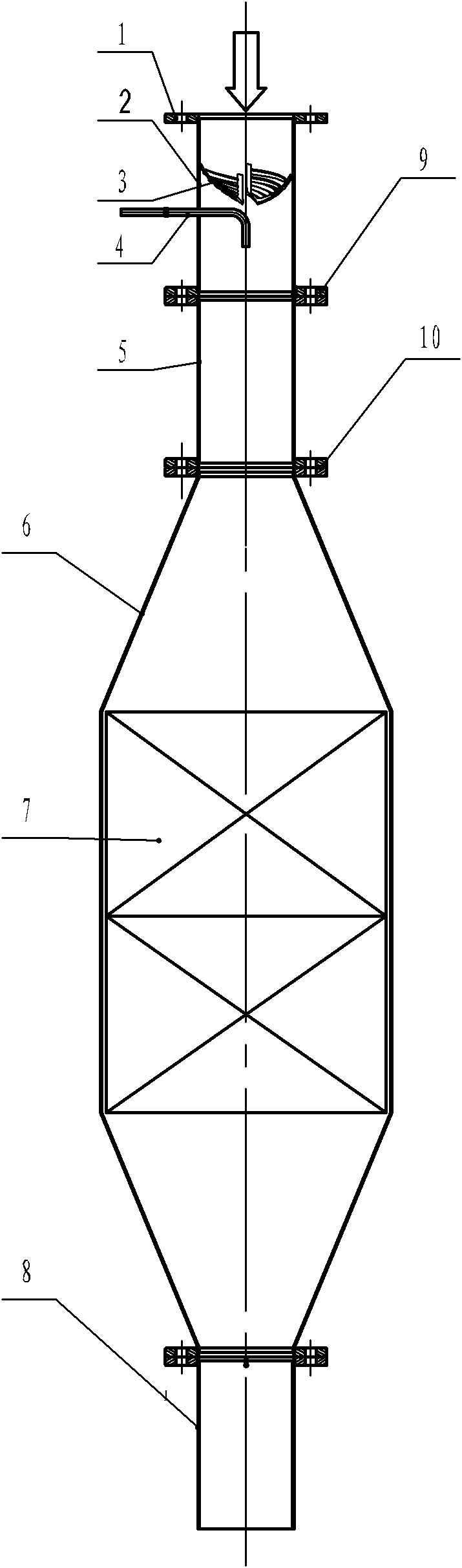

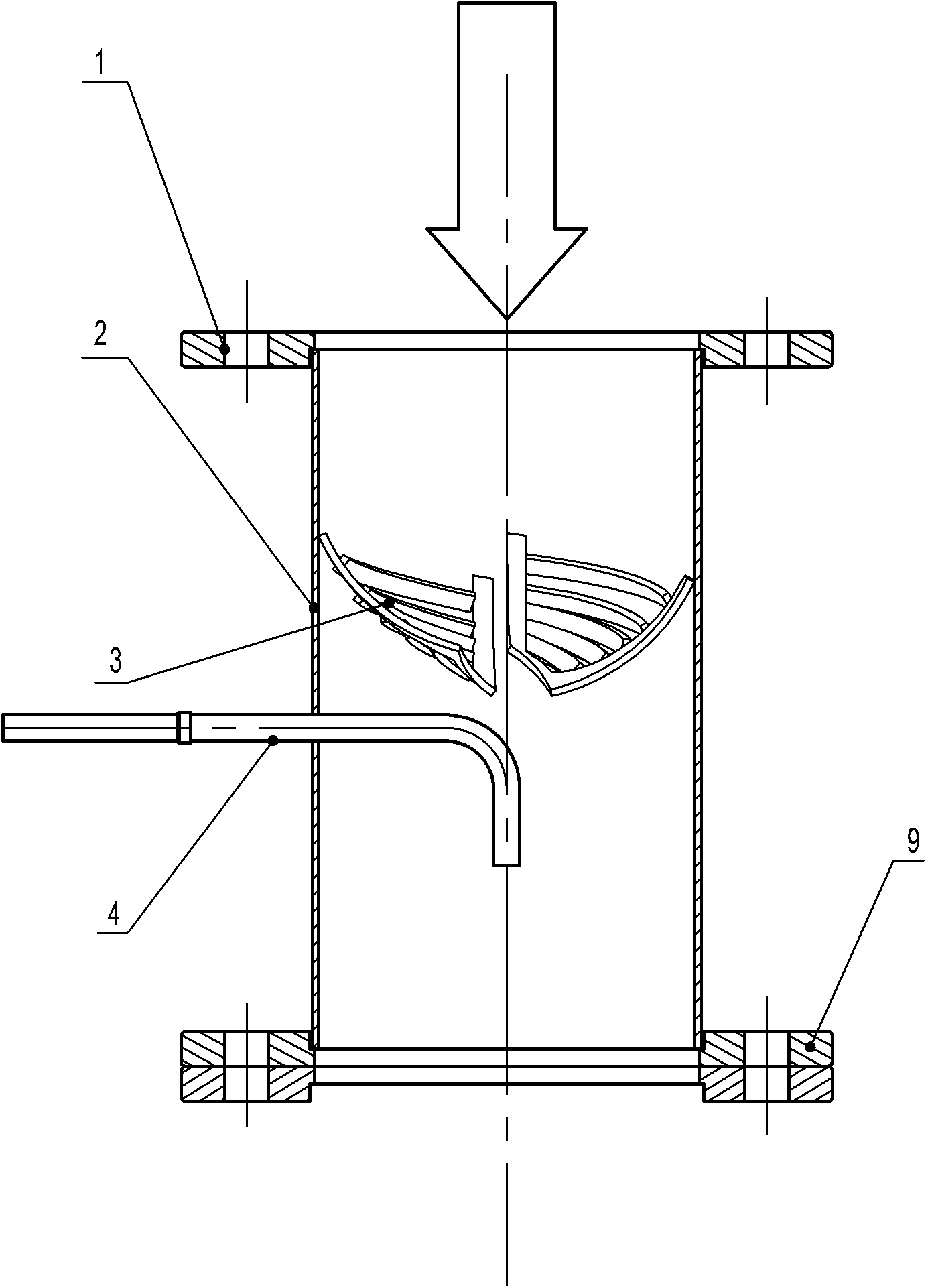

[0020] Below with reference to the accompanying drawings, by describing the embodiments, the specific implementation of the present invention, such as: the shape of each structure, structure and the mutual positional relationship and connection relationship between each part, the role and working principle of each part, etc. are further made A detailed description of:

[0021] The present invention is a mixing device for urea SCR system of diesel engine. The mixer is used to guide the gas flow in the exhaust pipe of the automobile, and a strong turbulent flow is formed at the outlet of the nozzle and in the direction of the spray axis, so that the urea aqueous solution can be better mixed with the automobile. Exhaust gas mixing to improve the uniformity of ammonia distribution and NO in the exhaust pipe X conversion efficiency, thereby further reducing the NOx content in the exhaust gas, and at the same time reducing the formation of urea crystals.

[0022] refer to image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com