Method for rapidly and continuously preparing size and feature controllable metal nano particles

A technology of metal nanoparticles and metal ions is applied in the field of preparation of metal nanoparticles to achieve the effects of low preparation cost, wide temperature range and overcoming uneven heating of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

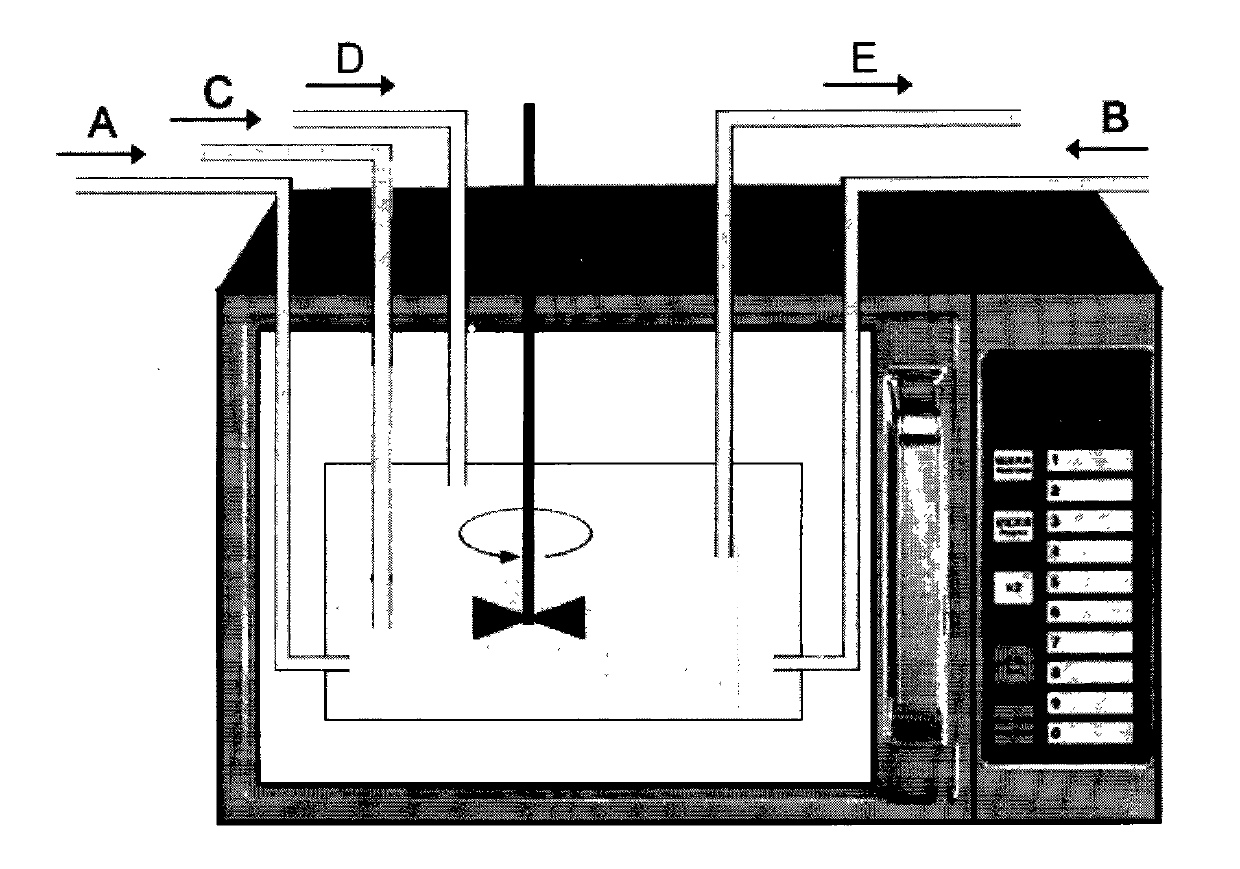

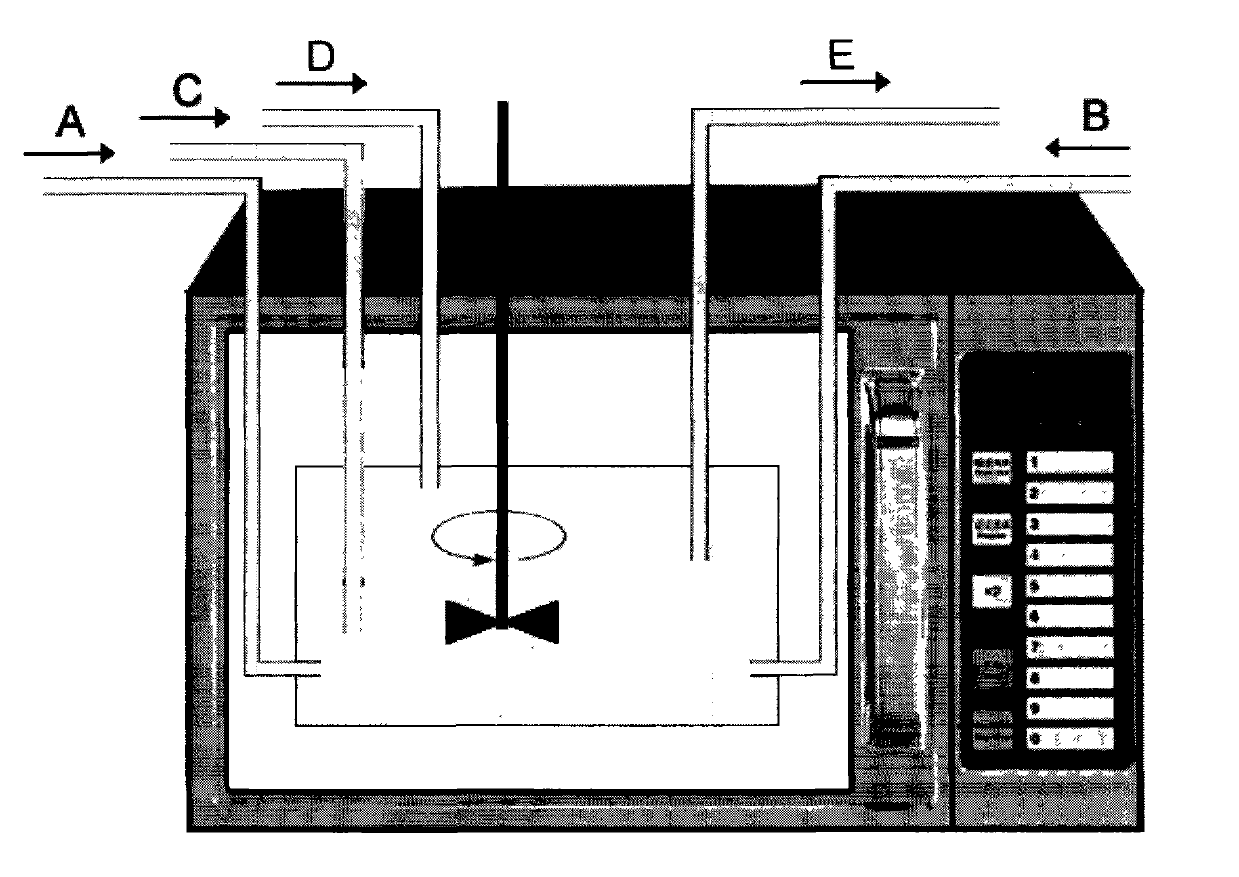

[0034] See figure 1 .

[0035]The PVP solution B and ethanol C of 0.2mmol / L chloroauric acid solution A, 2mmol / L, respectively pass through metal ion solution feed pipe A, stabilizer solution feed pipe B, reducing agent solution feed pipe C simultaneously and continuously Inject it into the reactor whose pressure is always maintained at atmospheric pressure, adjust the three solution flow rates VA, VB and VC of A, B and C, so that the flow rates of the three are the same, and the mol ratio of chloroauric acid to PVP in the obtained reaction solution is 1 : 10, while using microwaves with a frequency of 900 to 4500 MHz to heat the reactor, the reaction temperature in the reactor is set between room temperature and less than 100 ° C, and the reaction solution is stirred at a stirring rate of 800 rpm, so that Gold ions, PVP and ethanol are in full contact, and redox reactions occur; keep the reaction solution in the reactor and experience microwave irradiation for 1 minute to ob...

Embodiment 2

[0037] See figure 1 .

[0038] The PVP aqueous solution B of 0.6mmol / L chloroauric acid solution A, 6mmol / L and 3mmol / L sodium citrate solution C are fed through metal ion solution feeding tube A, stabilizer solution feeding tube B and reducing agent solution respectively. Feed pipe C is continuously injected into the reactor under atmospheric pressure all the time simultaneously, adjusts A, B and C three solution flow rates, makes the flow rate of the three identical, and in the obtained reaction solution, chloroauric acid: PVP: sodium citrate The molar ratio is 1:10:5, and the microwave heating reactor with a frequency of 900-4500 MHz is used at the same time, so that the reaction temperature in the reactor is set between room temperature and less than 100 ° C, and the stirring rate is 500 rpm. Stir the reaction solution so that the gold ions, PVP and sodium citrate are in full contact, and a redox reaction occurs; keep the reaction solution in the reactor and experience mi...

Embodiment 3~5

[0040] See figure 1 .

[0041] Put 0.2mol / L chloroauric acid aqueous solution A, 20mol / L PVP aqueous solution B and 0.2mol / L sodium citrate solution C through metal ion solution feeding tube A, stabilizer solution feeding tube B, and reducing agent solution respectively. At the same time, the feed pipe C is continuously injected into the reactor whose pressure is always maintained at atmospheric pressure, and the flow rates of A, B and C three solutions VA, VB and VC are adjusted to obtain the reaction liquid in the reactor, and the utilization frequency is 900-4500MHz at the same time The microwave heating reactor is used to set the reaction temperature in the reactor between room temperature and less than 100°C, and the reaction solution is stirred at a stirring rate of 300 rpm to fully contact the gold ions, PVP and sodium citrate , a redox reaction occurs; keep the reaction solution in the reactor and experience microwave irradiation for 3 minutes to obtain solution E, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com