Composite bactericide for paper making white water

A paper-making white water and composite technology, which is applied in the direction of paper, etc., can solve the problems of high irritation of organic bromine compounds, easy to corrode equipment, and difficult to decompose, and achieve the effects of inhibiting growth and reproduction, not corroding equipment, and fast penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The composite fungicide used for papermaking white water system described in this embodiment: the composition of its weight percentage is as follows:

[0018] 5-chloro-2-methylisothiazolin-3-one 2.7%, 2-methylisothiazolin-3-one 1.5%, polyhexamethylene monoguanidine hydrochloride 5% fungicide aqueous solution.

[0019] Its preparation method is: take 60kg of isothiazolinone derivatives respectively (5-chloro-2-methylisothiazolin-3-one, the mixed aqueous solution of 2-methylisothiazolin-3-one, the following examples are the same as ), 10kg of polyhexamethylene monoguanidine hydrochloride and 130kg of water are evenly mixed.

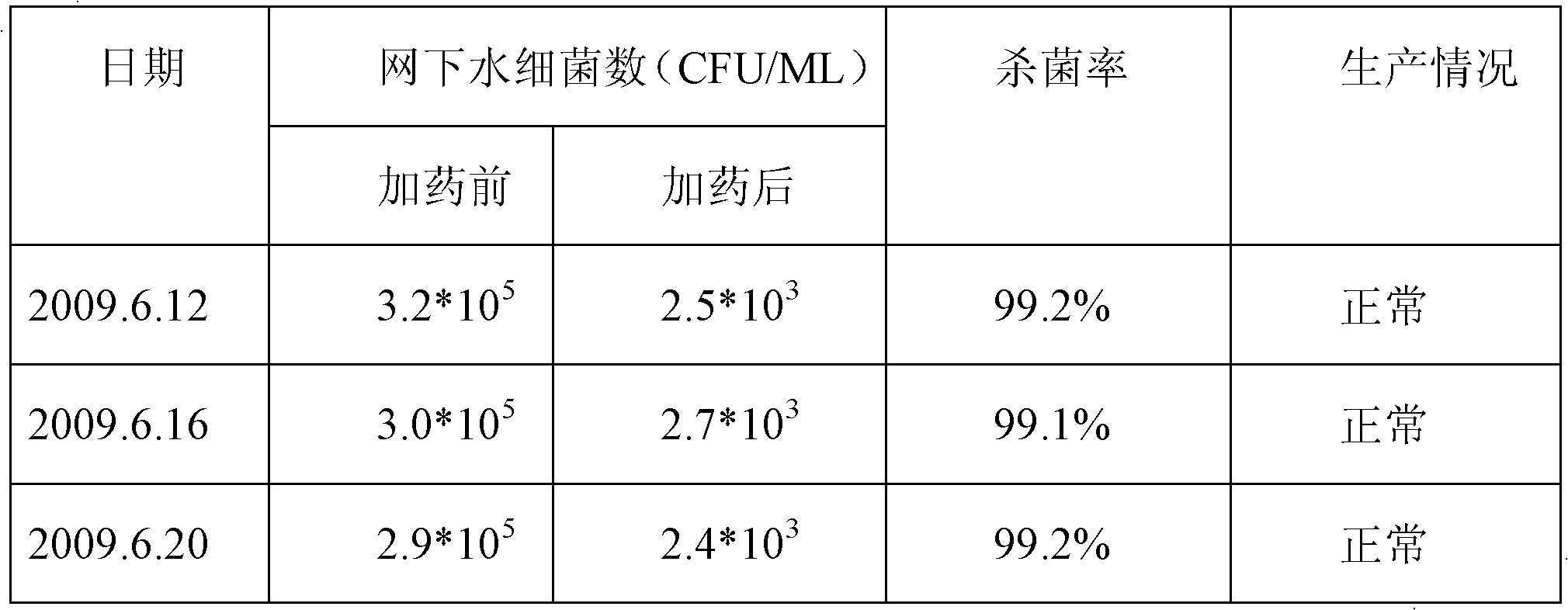

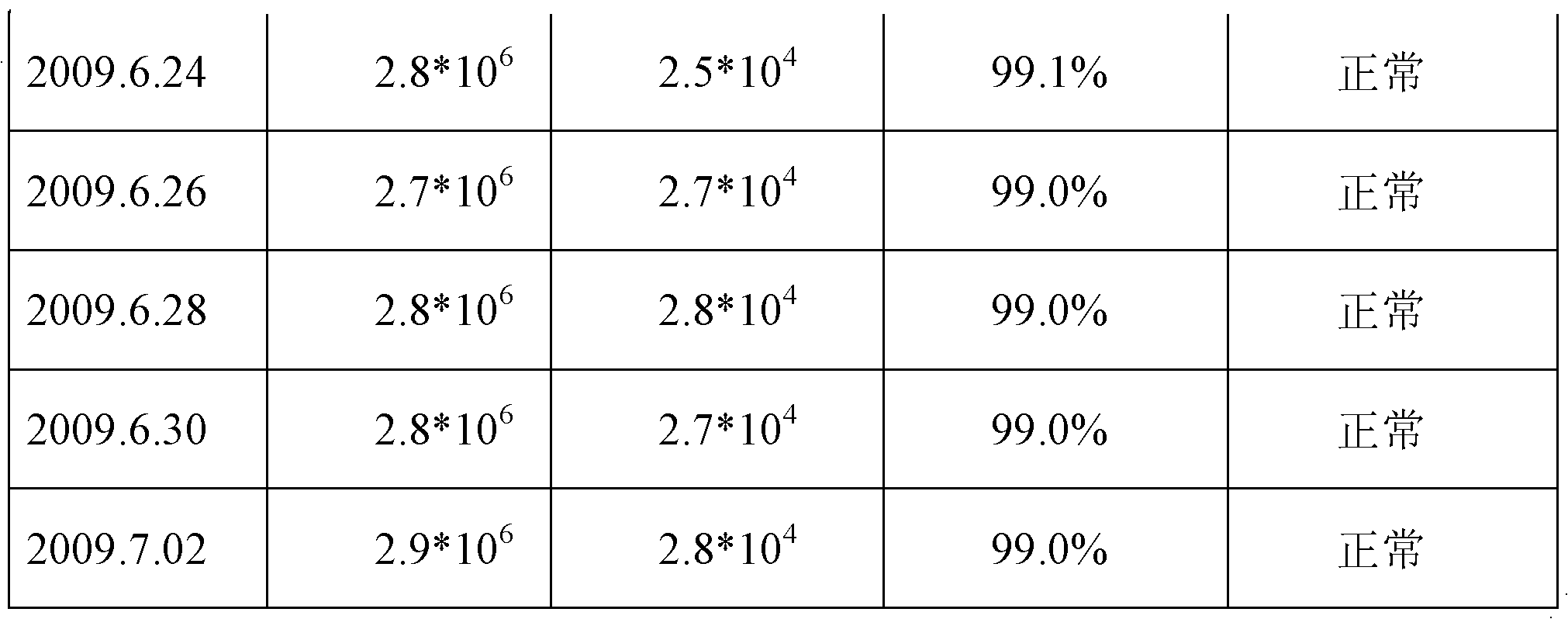

[0020] The application test was carried out on the 2350 paper machine of a paper mill in Hunan. The paper machine mainly uses wood pulp and reed pulp as raw materials, and produces 48-140g / m 2 For industrial coated base paper, the speed is 150-300m / min. The fungicide is added in front of the starch pool and the round sieve, and the interval-type au...

Embodiment 2

[0026] The composite fungicide used for papermaking white water system described in this embodiment: the composition of its weight percentage is as follows:

[0027] 5-chloro-2-methylisothiazolin-3-one 1.4%, 2-methylisothiazolin-3-one 0.8%, polyhexamethylene biguanide hydrochloride 15% fungicide aqueous solution.

[0028] 30 kg of the above isothiazolinone derivatives, 30 kg of polyhexamethylene biguanide hydrochloride and 140 kg of water were respectively taken and mixed uniformly.

[0029] The application test was carried out on the 1760 paper machine of a paper mill in Henan. This machine uses wood pulp and straw pulp as raw materials and produces 58-112g / m 2 High-white double-adhesive paper, the speed is 150-220 m / min. After alkaline washing, replace it with a compound fungicide, add it to the white water pool, and use impact-type automatic metering and dosing, dosing three times a day, one time lasts 15 minutes, and the flow rate is 80ml / min.

[0030] Test results Micro...

Embodiment 3

[0034] The composite fungicide used for papermaking white water system described in this embodiment: the composition of its weight percentage is as follows:

[0035] 5-Chloro-2-methylisothiazolin-3-one 1.8%, 2-methylisothiazolin-3-one 1.0%, polyhexamethylene monoguanidine phosphate 10% fungicide aqueous solution.

[0036] Take 40kg of the above isothiazolinone derivatives, 20kg of polyhexamethylene monoguanidine phosphate and 140kg of water and mix uniformly.

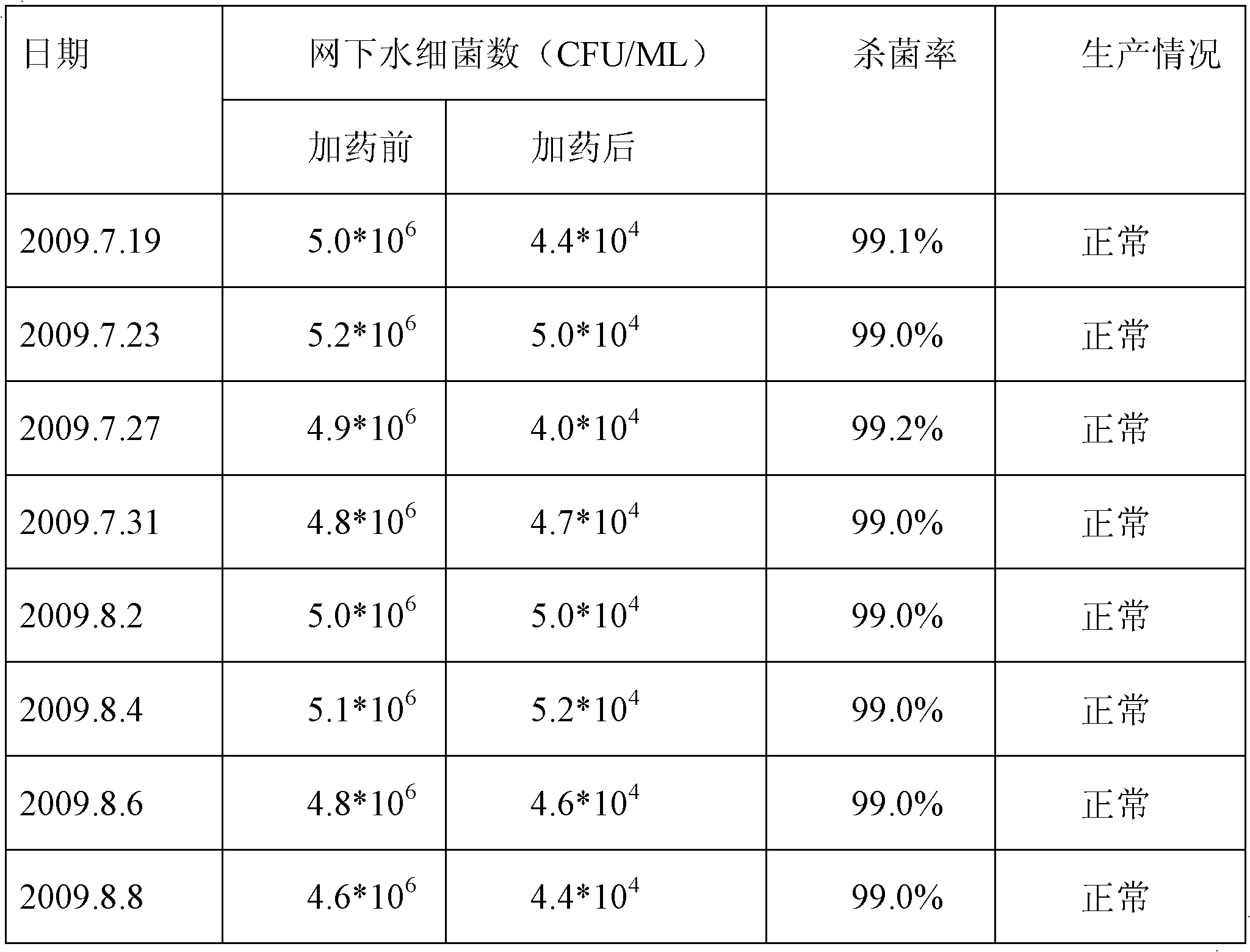

[0037] The application experiment was carried out on the 2640 paper machine of a paper mill in Henan, and the paper produced by the paper machine was 68g / m 2 Cultural double-adhesive paper, the type of pulp is wood and straw pulp, the speed is 480-530 m / min, the daily output of the paper machine is 120 tons, the dosing point is the white water pool, dosing three times a day, one time lasts 15 minutes, and the flow rate is 320ml / min.

[0038] Test results Microorganisms of the paper machine: (Tested with 3MPetuifilm t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com