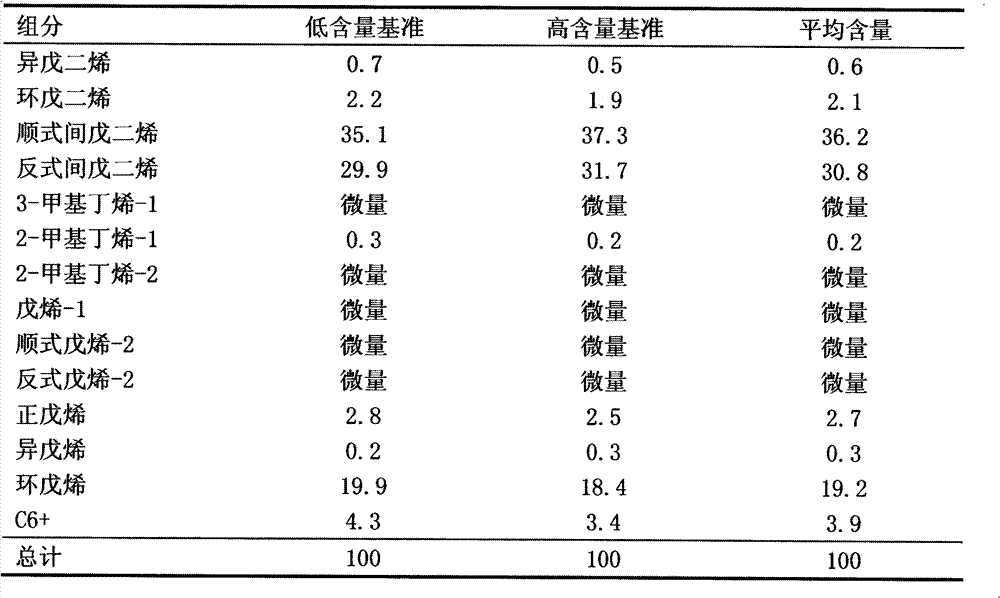

Method for synthesizing m-pentadiene petroleum resin by thermal polymerization

A technology for petroleum resin and piperylene, which is applied in the field of preparing piperylene petroleum resin, can solve the problems of high labor intensity, three wastes "pollution, influence on resin quality and application, etc., achieve high safety, improve economic benefits, The effect of easy continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add piperylene concentrate (see Table 2 for composition), solvent in proportion to the reaction kettle, use N 2 Replace 3 to 4 times, start to heat up, and start stirring. Control the heating rate to 60-90°C / h, control the reaction temperature to 300°C, the pressure to 2.1MPa, and the reaction time to 4h. After the reaction is finished, flash evaporate to obtain the product piperylene petroleum resin, the yield of the resin reaches 80%, the hue (Fe—Co)≤4 and the softening point of 92° C. can be obtained.

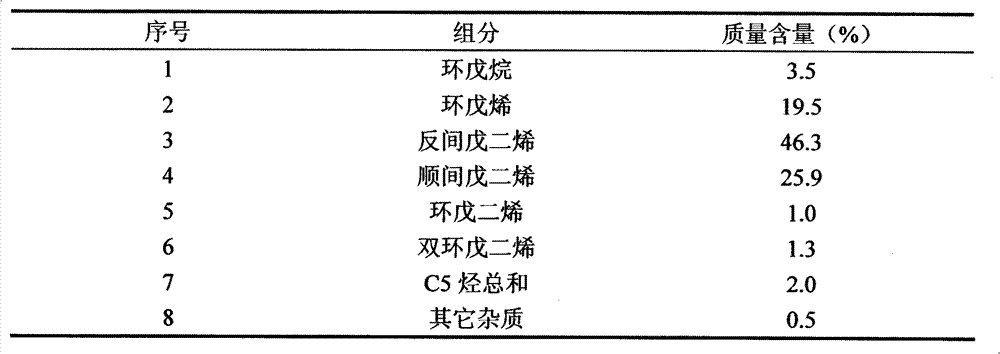

[0019] Table 2 Piperylene Concentrate Component Table

[0020]

Embodiment 2

[0022] The experimental process and raw materials are the same as in Example 1, the reaction temperature is changed to 310° C., the pressure is 2.2 MPa, and the reaction time is 5 hours. After the reaction, the non-polymer is flashed off to obtain the product piperylene petroleum resin, the resin yield reaches 83%, the hue (Fe—Co)≤5 and the softening point of 94° C. can be obtained.

Embodiment 3

[0024] The experimental process and raw materials were the same as in Example 1, the reaction temperature was changed to 320° C., the pressure was 2.3 MPa, and the reaction time was 4 hours. After the reaction, the non-polymer is flashed out to obtain the product piperylene petroleum resin, the resin yield reaches 84%, the hue (Fe—Co)≤6 and the softening point of 97° C. can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com